-18-

Model T25100 (Mfg. Since 8/12)

Review the troubleshooting and procedures in this section if a problem develops with your machine. If you

need replacement parts or additional help with a procedure, call our Technical Support at (570) 546-9663.

Note: Please gather the serial number and manufacture date of your machine before calling.

SECTION 7: SERVICE

Troubleshooting

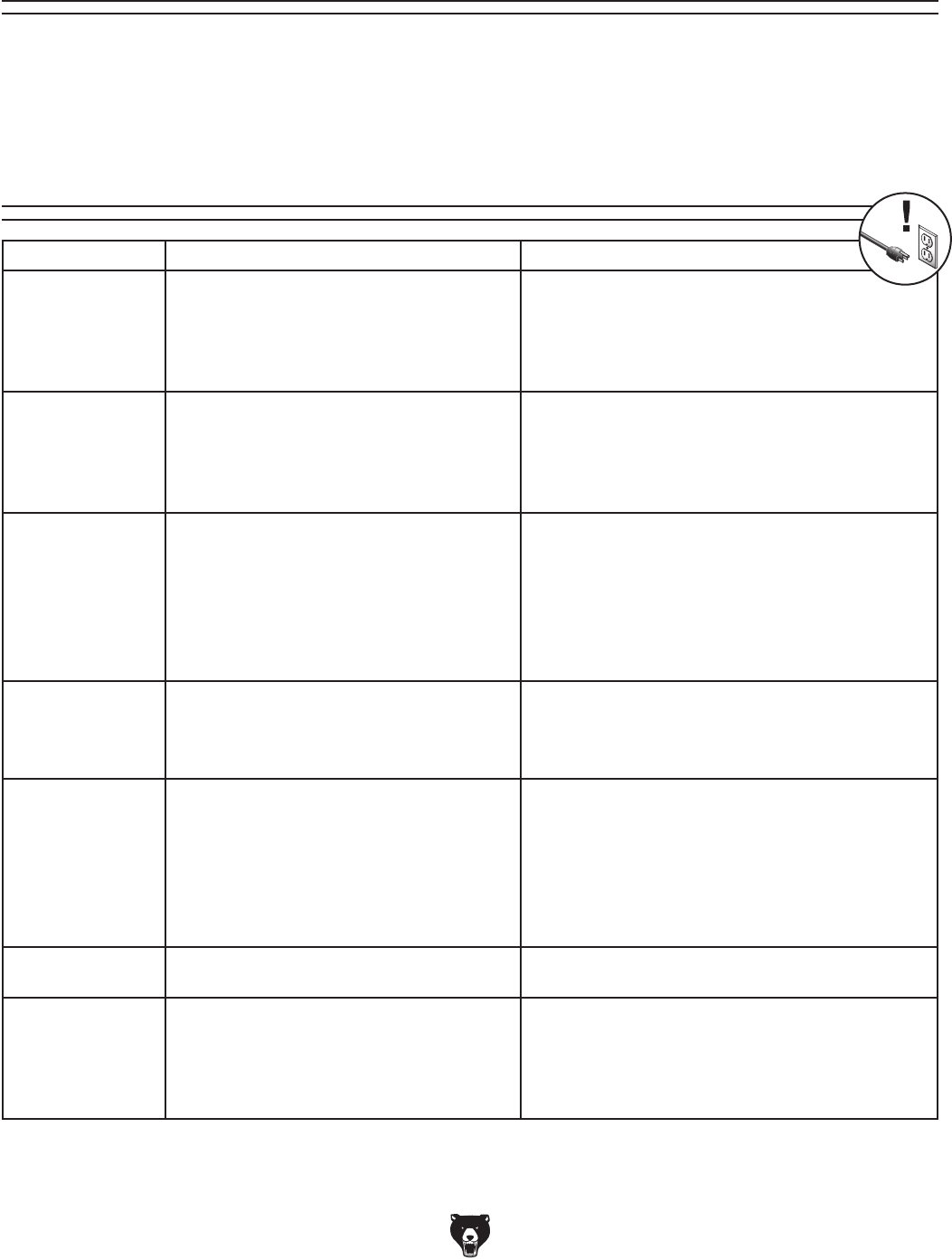

Symptom Possible Cause Possible Solution

Tool does not turn

on.

1. Control box fuse is blown.

2. Power source turned OFF at breaker.

3. Wall fuse/circuit breaker is blown/tripped;

short in electrical system.

4. ON/OFF switch at fault.

1. Replace control box fuse (0.5A, Fast-Acting)

2. Make sure circuit breaker is turned ON.

3. Troubleshoot/repair source cause of overload;

replace weak breaker; find/repair electrical short.

4. Replace switch.

Poor adhesion. 1. Workpiece not properly cleaned/pre-treated

prior to spraying.

2. Coating under/over-cured.

3. Powder coat too thick.

1. Thoroughly clean workpiece; research/perform

pretreatment recommendations for workpiece

material and powder.

2. Follow powder manufacturer's curing instructions.

3. Reduce powder coat thickness when spraying.

Uneven spray

pattern, intermittent

powder flow.

1. Blockage in spray gun body/powder cup.

2. Damp powder.

3. Air pressure low.

4. Powder flow regulating screw too tight.

1. Disconnect tool from power, ground conducting

pole, put on protective gear, and use air pressure to

thoroughly clean spray gun and powder cup.

2. Check powder source; replace powder if

contaminated; replace in-line moisture filter(s).

3. Increase air pressure up to 30 PSI.

4. Loosen screw to increase powder flow.

Chipping after

curing.

1. Workpiece not properly cleaned/pre-

treated.

2. Powder coat too thick.

1. Thoroughly clean workpiece; research/perform

pretreatment recommendations for workpiece

material and powder.

2. Reduce powder coat thickness when spraying.

Cratering after

curing.

1. Powder is contaminated.

2. Workpiece not properly cleaned/pre-treated

prior to spraying.

3. Damp powder.

1. Thoroughly clean spray gun/powder cup; replace

power with new.

2. Thoroughly clean workpiece; research/perform

pretreatment recommendations for workpiece

material and powder.

3. Check powder source; replace powder if

contaminated; replace in-line moisture filter(s).

Off color after

curing.

1. Oven not properly ventilated.

2. Incorrect curing time/temperature.

1. Make sure oven is well ventilated during curing.

2. Follow powder manufacturer's curing instructions.

Orange peel. 1. Warming up of powder coat is too slow or

too fast.

2. Powder heat-damaged prior to spraying.

3. Coating too thin.

1. Check curing oven for proper operation; follow

powder manufacturer's curing instructions.

2. Thoroughly clean spray gun/powder cup; replace

powder with new.

3. Increase coating thickness when spraying.