-14-

Model T25100 (Mfg. Since 8/12)

Workpiece

Preparation

The powder coating system is designed to

ONLY operate on solid, electrically-conduc-

tive metal workpieces.

Follow these workpiece preparation guide-

lines for the best results:

• Thoroughly clean the workpiece of paints or

other finishes, residue left by cleaning solu-

tions, debris, dust, and any other foreign

material. Depending upon the application,

additional pre-treatment steps may be neces-

sary.

• Make sure the workpiece is completely dry.

• Attach the grounding clip (see Figure 8) to

the workpiece or hanger with a good metal-

to-metal contact at a point where the pow-

der will not be applied. This will provide a

negative electrical attraction for the charged

power.

Figure 8. System grounding clip.

• Use clean metal material for workpiece hang-

ers. This will ensure that the hanger is

grounded with the workpiece.

Scatter Tips

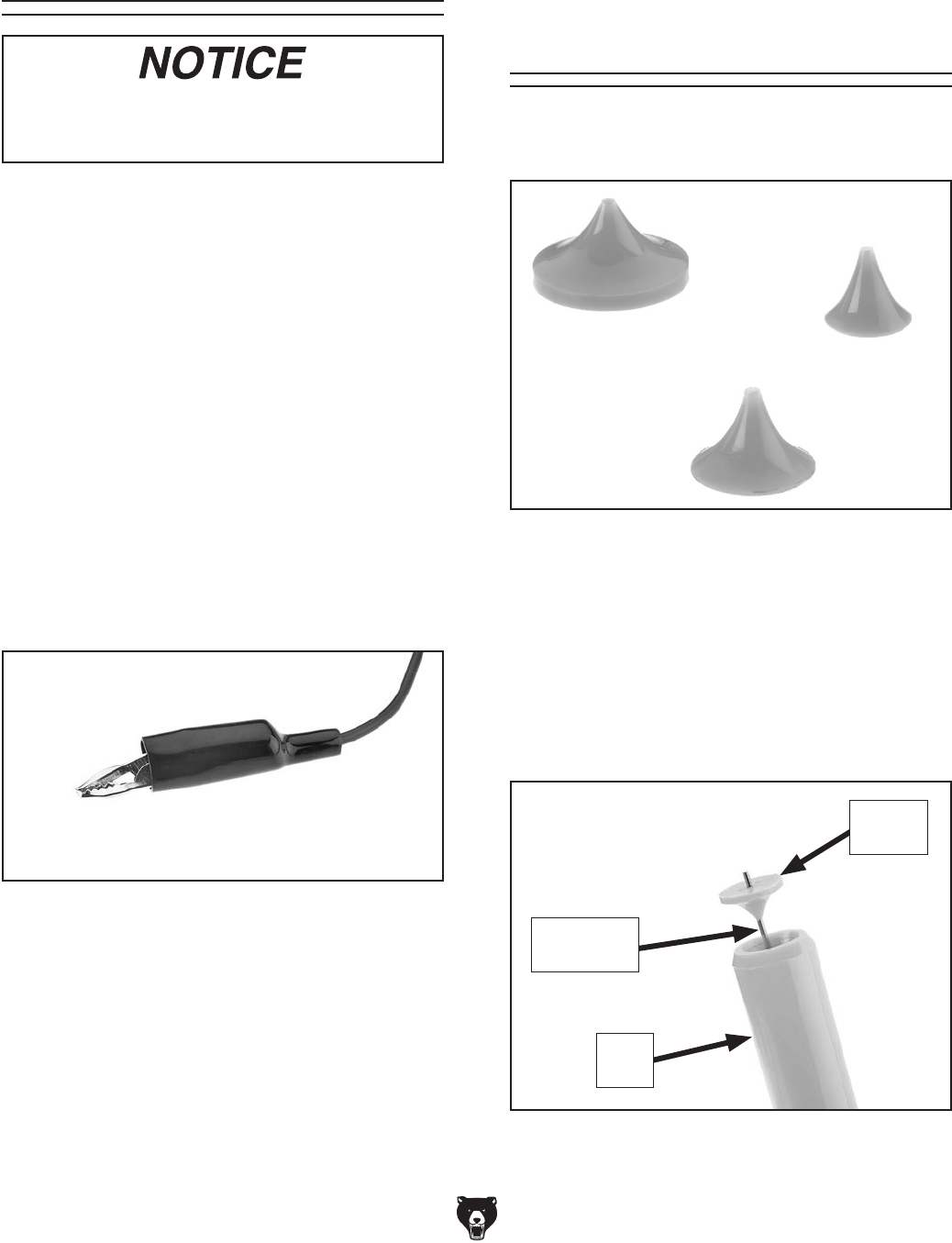

The Model T25100 ships with three scatter tips

with diameters of

1

⁄2",

3

⁄4", and 1" (see Figure 9).

Figure 9. Included scatter tips.

The scatter tips thread onto the conductor pole

(see Figure 10) and produce different spray pat-

terns. Experiment with a scrap workpiece to gain

an understanding of the effect that each tip pro-

duces.

Note: Wipe the tips clean of powder before stor-

ing them.

Figure 10. Scatter tip installed.

Conductor

Pole

Scatter

Tip

Gun

Nose

• Make sure the workpiece is not touching any

other grounding source other than the pow-

der coating system ground.

• To reduce the risk of electrical shock from

workpiece contact, position or hang the

workpiece so that it does not need to be

re-positioned during the powder coating pro-

cess.