1. Unscrew the threaded Oil Dipstick to re-

move it from the oil reservoir.

2. Look at the oil level on the dip stick. The

proper oil level is shown on the illustration

to the right.

3. If the oil level is low, add standard, non-

detergent 30-weight non detergent compres-

sor oil, (use lighter weight oil for cold

weather operation). Add a little at a time,

and check the level before each addition.

Do not overfill. If overfilled, you can re-

move the drain plug to allow oil to drain

out.

4. When the oil level is correct, replace the

dipstick.

SET UP & OPERATION

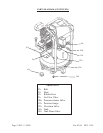

Figure 2 — Connecting the Air Compressor

Page 5 SKU # 38898 Rev 02/01 REV 03/04 REV 05/05

Your compressor is fully assembled when you receive it. Before using it, perform the following set up

operations.

Before using your compressor for the first time,

check to be sure the oil reservoir is filled.

Next, connect your air hoses, filter and regula-

tor to the compressor, as illustrated in Figure 2

below.

1. The provided air outlet is 1/4” NPT. Connect the high pressure air hose to the air outlet.

Note: For easy connection or removal, a quick coupler (included) should be installed on the

end of the outlet (a female and a male coupler are also included to use with the quick coupler).

2. For best service, you should incorporate an oiler, a regulator, and a filter in line; as shown in the

above diagram.

3. Hoses, Couplings, Fittings, Oilers, Regulators, and Filters are all available from Harbor Freight

Tools.

Warning: Fill with compressor oil before using;

running with NO or LOW OIL voids warranty.

Warning: Do not remove

factory sealed Air Flow Valve

(#9A); removal of valve voids

warranty.

Note: Optimal oil tank capacity is 7.8 ounces.

NOTE:

Use Pipe Thread Seal tape on all

threaded connections.

Figure 1. Checking the Oil Level

Oil

Dipstick

Proper

Oil Level