Page 12SKU 66787 For technical questions, please call 1-800-444-3353.

Protective gear must be worn

when using the Welder; ANSI-

approved, arc shaded, eye

protection, a full face shield,

heavy duty work gloves, a

welding apron, respirator,

and heavy-duty work clothes

without pockets should be

worn when using this product.

Do not look at the ignited

arc without eye protection.

Light from the arc can cause

permanent damage to the

eyes. Light from the arc can

burn the skin. Do not breathe

arc fumes.

The 1. duty cycle denes the number

of minutes, within a 10 minute period,

during which a given Welder can

safely produce a particular welding

current. For example, this Welder,

with a 40% duty cycle at 130 Amps

(maximum setting), must be allowed

to rest for at least 6 minutes after

every 4 minutes of continuous weld

at 130 Amps.

Failure to carefully observe duty cy-•

cle limitations can stress a Welder’s

power generation system, contribut-

ing to premature Welder failure.

This Welder is equipped with an •

internal thermal protection system

to help prevent damage to the unit.

When the unit overheats; it auto-

matically shuts down, then returns

to service when it cools down.

Once the unit returns to service, fol-•

low a more conservative duty cycle

routine to help prevent excess wear

to the Welder.

Mount the metal to be welded to the 2.

metal work table. It should be mount-

ed so that the welding debris falls to

the cement oor.

Place the Welder no closer than six 3.

feet from the workpiece to be welded

and attach the Tig Torch, if desired.

Securely attach the Ground Clamp 4.

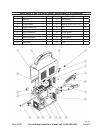

(9) to a part of the workpiece or metal

table. (See Figure A.)

Place the bare end of an Electrode 5.

(not included) in the Electrode Holder

(8). NOTE: Always keep the jaws of

the Electrode Holder clean to ensure

proper electrical contact with the

Electrode. (See Figure A.)

Set the desired current on the Poten-6.

tiometer Dial (4) from 10 to130 amps

for the type of metal being welded.

Thin metals use low current and

heavy metals use high current.

(See Figure B.)

Make sure the Power Switch (16) is 7.

OFF. Then plug the Welder’s Power

Cord (17) into the nearest 240 volt,

dedicated, grounded, electrical outlet

with delayed action type circuit break-

er or fuse. (See Figure C.)

While gripping the Handle of the 8.

Electrode Holder (8), with the Elec-

trode clear of grounded objects, turn

the Power Switch (16) ON.

(See Figure C.)

Hold the Electrode Holder (8) rmly. 9.

CAUTION! The Electrode Holder is

“live”. (See Figure A.)

WARNING! 10. Never look at the ignited

arc without ANSI-approved, arc shad-

ed, eye protection in a full face shield.

Permanent eye damage or blindness

can occur. Skin burns can occur.

REV 09h