Page 9SKU 66787 For technical questions, please call 1-800-444-3353.

SPECIFICATIONS

Electrical

Requirements

240V~ / 60 Hz / 25A max.

Power Cord: SJT 12AWG x 3C

Power Plug: 3-Prong, 240 VAC

(Not Included)

Output

Amperage

Range

10-130 Amps

Maximum

Open Circuit

Voltage

61V

Duty Cycle

40% @ 130 Amps

60% @ 120 Amps

100% @ 80 Amps

Maximum

Welding

Capacity

1/4” - For Welding Steel Only

Electrode

Diameter

Capacity

For Use With

1/16”, 3/32” and 1/8” Diameter

Rods

Electrode

Holder Head

Ground Cable

75”

65”

Torch Cable

Length

12’ 9”

Gas Hose 8’ 6” L, 0.34” OD, .19” ID

Additional

Features

May be used for both arc and tig

welding.

Quick starting with high open

voltage.

Anti-Stick circuit works with

rutile, basic steel, stainless

steel, and cast iron electrodes.

Additional amperage during

short arc length conditions

increases electrode penetration.

UNPACKING

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

Note: For TIG Welding Torch Parts

List and Diagram, refer to page 17.

REV 09h, 09l

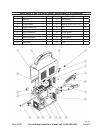

When assembling Torch, make 1.

sure Torch Cable is not connected

to Welder or argon gas supply.

Ceramic

Nozzle

(3a/3b)

Rod

Holder

(2a)

Gas Flow

Knob

Handle

(Front)

(Back)

2. Thread either Rod Holder (2a) or Plug

(6a) securely into back of Torch (1a).

Choose a matching set of Collet and 3.

Collet Holder, either 1/16” (4a & 5a)

or 3/32” (4b & 5b), depending on the

rod to be used. Insert the Collet, nar-

rower end rst, into the Collet Holder,

and then thread the Collet Holder

loosely into the front of the Torch.

Place a prepared tungsten welding 4.

rod (the correct diameter for the Col-

let used) into Collet. Tighten Collet

Holder in place.

Attach desired Ceramic Nozzle (3a or 5.

3b) onto Collet Holder. Do not over-

tighten. Ceramic Nozzles of larger

sizes will contain shielding gas in a

larger area, but may require more gas

ow to be effective.

Connect the gas hose securely to the 6.

regulator on the argon bottle. Set the

argon regulator to 18-22 PSI. Fol-

low the gas cylinder manufacturer’s

instructions for set-up and use.

Connect the cable to the Welder. 7.

Twist to lock in place.

TORCH ASSEMBLY