Page 7SKU 93119

For technical questions, please call 1-800-444-3353.

Troubleshooting

In the event the pot is not operating properly, refer to the following table for troubleshooting

procedures.

Problem Possible Cause Possible Solution

Air escapes from the port on

the regulator cap.

A broken or damaged dia-

phragm.

Replace the diaphragm.

Pressure drops slowly on the

gauge.

A dirty or worn valve seat in

the regulator.

Clean or replace the valve

seat.

Paint tends to settle in can

rapidly.

Insufficient mixing of the

paint.

Mix or thin the paint according

to the manufacturer’s instruc-

tions before spraying.

Fluid or air leaks from the lid

gasket.

A defective lid gasket or loos-

ened thumb screw.

Replace the gasket or tighten

the thumb screw.

Safety valve is stuck, does not

operate freely or does not re-

lieve pressure.

Damaged valve. Replace the safety valve.

Safety valve popping off. Tank pressure too high.

Reduce tank pressure 30-60

PSI.

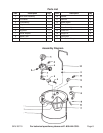

Accessories

The following accessories are available for use with the Paint Pressure Pot:

An Air Regulator Kit can be used as an independent monitor of both air and fluid pressure.

It can be used with portable air compressors or with air lines when no other means of air

pressure regulation (air filters or regulators) is available.

An Air Adjusting Valve gives the operator more control and reduces air use at the gun.

The valve is ideal for low pressure spraying.

A Rubber Lid Gasket can be used when the material being sprayed is not compatible with

the supplied gasket.

An Intake Strainer connects to the fluid inlet tube, preventing lumps and foreign matter

from entering the fluid lines.