SKU 95082 For technical questions, please call 1-800-444-3353. Page 8

SPECIFICATIONS

Electrical Requirements 120 V~ / 60 Hz / 11.8 A

Motor (Cutter head)

Speed

2-1/2 HP, 18,800 cuts

per minute

Maximum Cutting Depth 3/32”

Stock Capacity 4-1/2” x 12” lumber

Feed Speed 20 Feet per Minute

Included

Accessories

1 Hex Wrench (4mm)

2 Magnets, 1 Dust Bag,

UNPACKING

When unpacking, check to make sure

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at the number shown on the

cover of this manual as soon as possible.

INSTRUCTIONS FOR

PUTTING INTO USE

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION: Turn the Power

Switch of the tool to its “OFF”

position and unplug the tool

from its electrical outlet

before assembling or making

any adjustments to the tool.

Note: For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Assembly

NOTE: 1. This should always be mount-

ed to a workbench before use.

Select an area with enough room to 1.

Select a workbench to mount the

Planer. Place the Planer on a work-

bench able to support the weight of

the Planer and the wood stock being

planed. The orientation of the Planer

should enable the easy entry and exit

of long pieces of wood stock.

Using a pencil, mark through the 2.

mounting holes of the Planer, onto

the workbench. Slide the Planer

aside and drill four 3/8 inch mounting

holes into the workbench.

Before drill-

ing, verify that there are no utility

wires or other obstructions under

the workbench.

Slide the Planer back over the mount-3.

ing holes in the workbench, and se-

cure the Planer to the workbench with

bolts, washers, spring washers and

nuts (not included). Securely tighten.

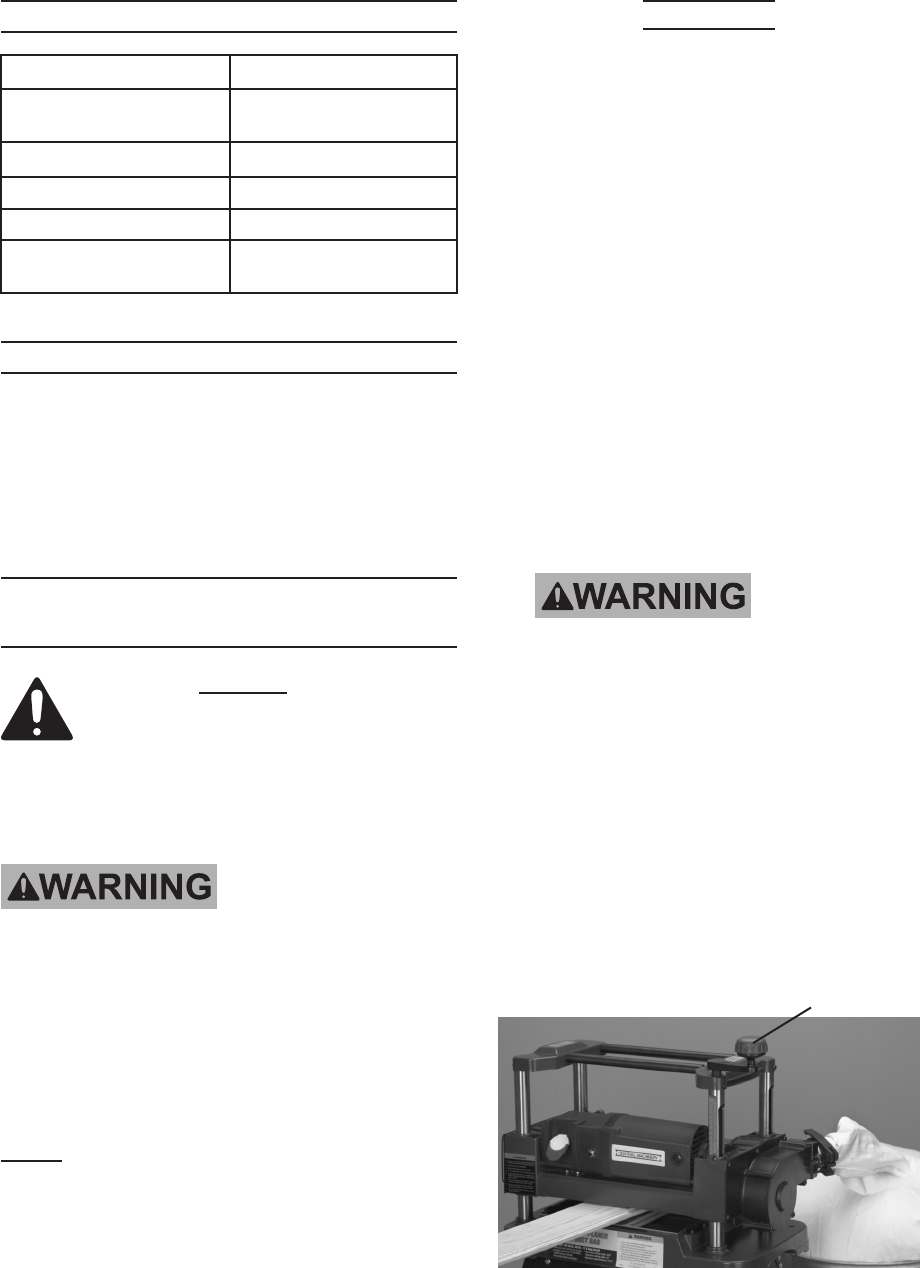

Mount the height (thickness) adjust-4.

ment Handle (10) to the Right Cap

(11). See Figure A.

Figure A

Crank

Handle (10)

Rev 10d