English

23

(6) Clearance of the socket (WR12DM2, WR9DM2)

A worn or deformed hex. or a square-holed socket will not give an adequate tightness

to the fitting between the nut or anvil, consequently resulting in loss of tightening

torque.

Using an improper socket which does not match to the bolt will result in an insufficient

tightening torque. Matching socket and bolt sizes are shown in Table 4, 5, 6 and 7.

(7)Tightening torque varies, depending on the battery’s charge level (WR12DM2, WR9DM2)

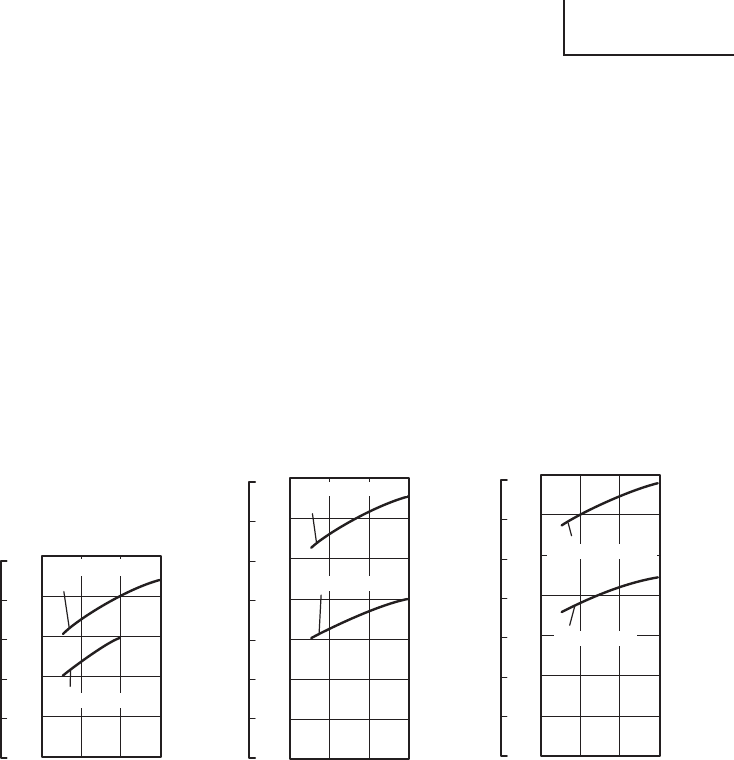

Fig. 22 and 23 show an example of the relationship between tightening torque and the

number of tightenings. As shown, tightening torque gradually weakens with the increase

in the number of tightenings. In particular, as the torque decreases very close to the

complete discharge (“a” margin in graph), the unit’s impact weakens, the number of

time impacts declines and tightening torque drops off abruptly. If this occurs, check

torque level, then recharge the battery if necessary.

9/16"×1-15/16"

(M14×50)

0123

kgf·cm

(in-lbs)

(1215)

(1042)

(868)

(694)

(521)

(347)

(174)

1400

1200

1000

800

600

400

200

0

N·m

140

120

100

80

60

40

20

0

15/32"×1-3/4"

(M12×45)

0 123

kgf·cm

(in-lbs)

N·m

(1215)

(1042)

(868)

(694)

(521)

(347)

(174)

140

120

100

80

60

40

20

0

1400

1200

1000

800

600

400

200

0

0 123

kgf·cm

(in-lbs)

1000

800

600

400

200

100

80

60

40

20

0

(868)

(695)

(521)

(347)

(174)

0

3/8"×1-5/32"

(M10×30)

N·m

Tightening torque

Tightening torque

Tightening torque

Tightening time: sec

(Steel plate thickness

t = 1" (25 mm))

Tightening time: sec

(Steel plate thickness

t = 1" (25 mm))

Tightening time: sec

(Steel plate thickness

t = 3/8" (10 mm))

Fig. 17

Ordinary bolt

High strength bolt

High strength bolt

Ordinary bolt

High strength bolt

Ordinary bolt

<For WH12DM2>