OM-951 Page 13

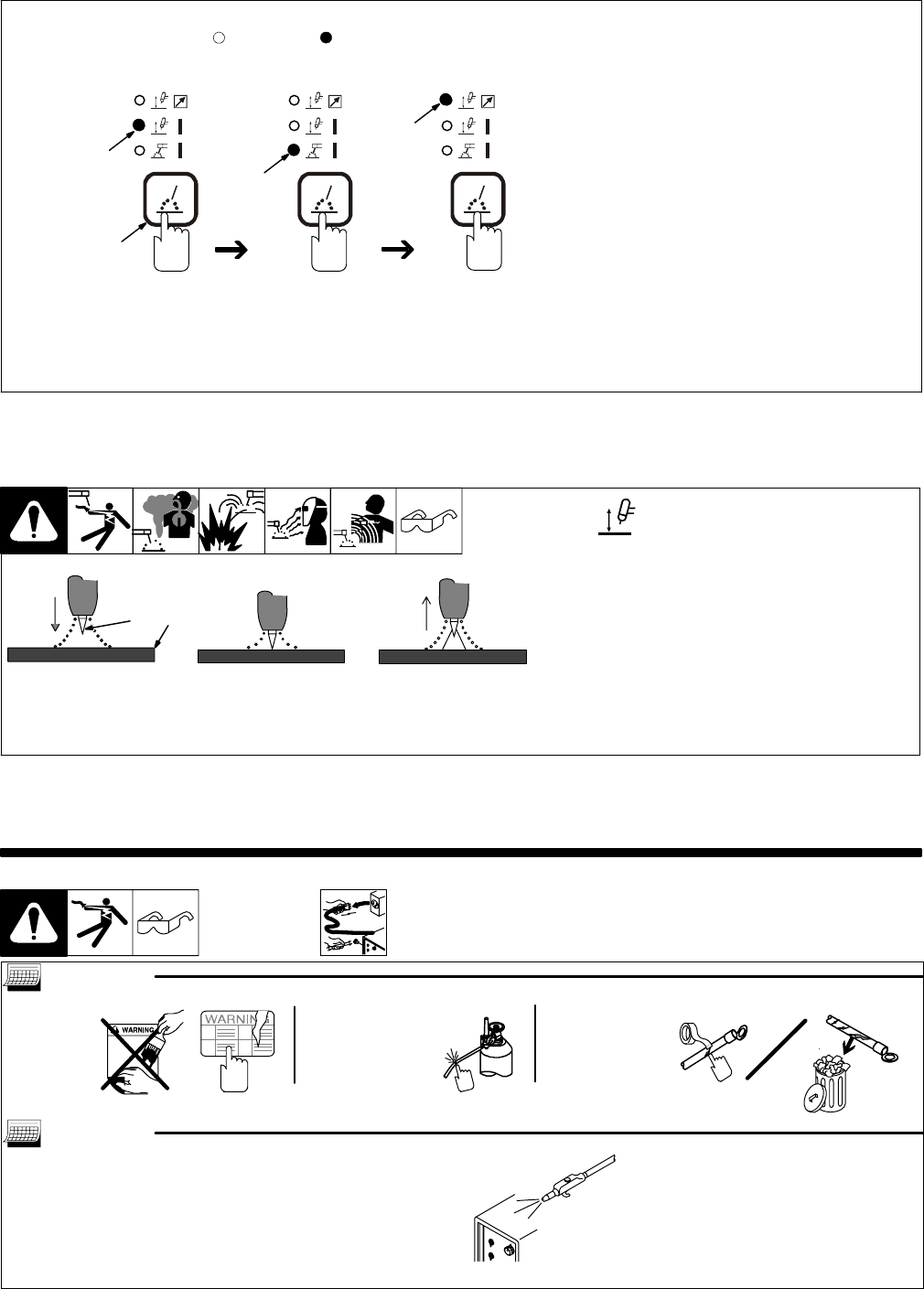

5-2. Process Selection

1 Process Selector Switch Pad

Use control to select required welding

process. Press switch pad until LED

for desired process is illuminated.

2 Lift Arct Start

When selected, a TIG arc starting

method in which the electrode must

come in contact with the workpiece to

initiate an arc is activated (see Section

5-3).

3 Stick (SMAW)

When selected, Adaptive Hot Start

and DIG circuitry are energized.

4 Lift Arct Start (Remote)

A TIG starting method in which the

electrode must come in contact with

the work and a closure from pin 1 to pin

2 on the remote receptacle (see Sec-

tion 4-6) is required to initiate an arc.

1

Press Press

2

3

=Light Off =Light On

Press

4

5-3. Lift-Arc™

Lift-Arc Start

1 TIG Electrode

2 Workpiece

Touch tungsten electrode to work-

piece, hold for 1-2 seconds, slowly

lift electrode, and an arc forms.

Open-circuit voltage may be present

before electrode touches workpiece.

1

1 − 2

Seconds

“Touch”

Do NOT Strike Like A Match!

2

SECTION 6 − MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

Y Disconnect power before maintaining.

. Maintain more often during severe conditions.

3 Months

Replace

unreadable

labels.

Replace Damaged

Gas Hoses

Repair Or Replace

Cracked Cables

And Cords

6 Months

Blow out inside. Direct airflow through front and back louvers.

Y Do not remove case when blowing out inside of unit .