OM-184 693 Page 7

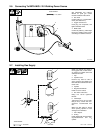

2-6. Connecting To BETA-MIG 251 Welding Power Source

801 758-A

1 Spool Gun Control Module

See BETA-MIG 251 Owner’s

Manual for spool gun control

module installation instructions.

2 Gas Hose

Connect fitting to regulator/flow-

meter (see Section 2-7).

3 Trigger Control Cord

Insert plug into receptacle, and

tighten threaded collar.

4 Weld Cable

Connect to positive (+) weld output

terminal on welding power source

according to its Owner’s Manual.

Tools Needed:

1-1/8, 5/8 in

1

2

3

4

+

_

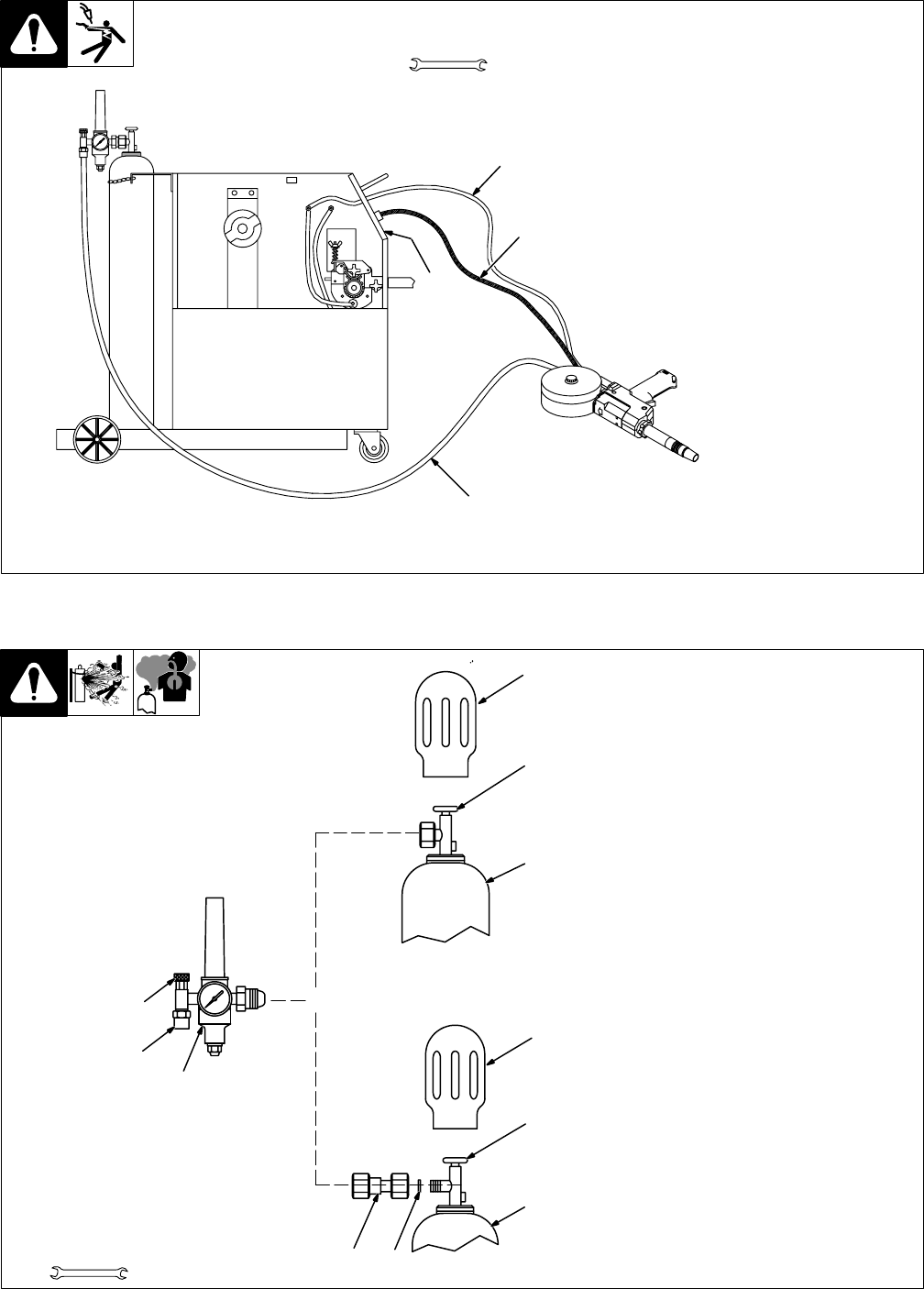

2-7. Installing Gas Supply

ssb3.1* 5/94 – 158 697-A

Obtain gas cylinder and chain to

running gear, wall, or other station-

ary support so cylinder cannot fall

and break off valve.

1 Cap

2 Cylinder Valve

Remove cap, stand to side of

valve, and open valve slightly. Gas

flow blows dust and dirt from valve.

Close valve.

3 Cylinder

4 Regulator/Flowmeter

Install so face is vertical.

5 Gas Hose Connection

Fitting has 5/8-18 right-hand

threads.

6 Flow Adjust

Typical flow rate is 20 cfh (cubic

feet per hour). Check wire man-

ufacturer’s recommended flow

rate.

Make sure flow adjust is closed

when opening cylinder to avoid

damage to the flowmeter.

7CO

2

Adapter

8 O-Ring

Install adapter with O-ring between

regulator/flowmeter and CO

2

cylinder.

Tools Needed:

1-1/8, 5/8 in

CO

2

Gas

7

8

3

1

2

4

5

6

1

2

3

Argon Gas

OR