OM-184 693 Page 13

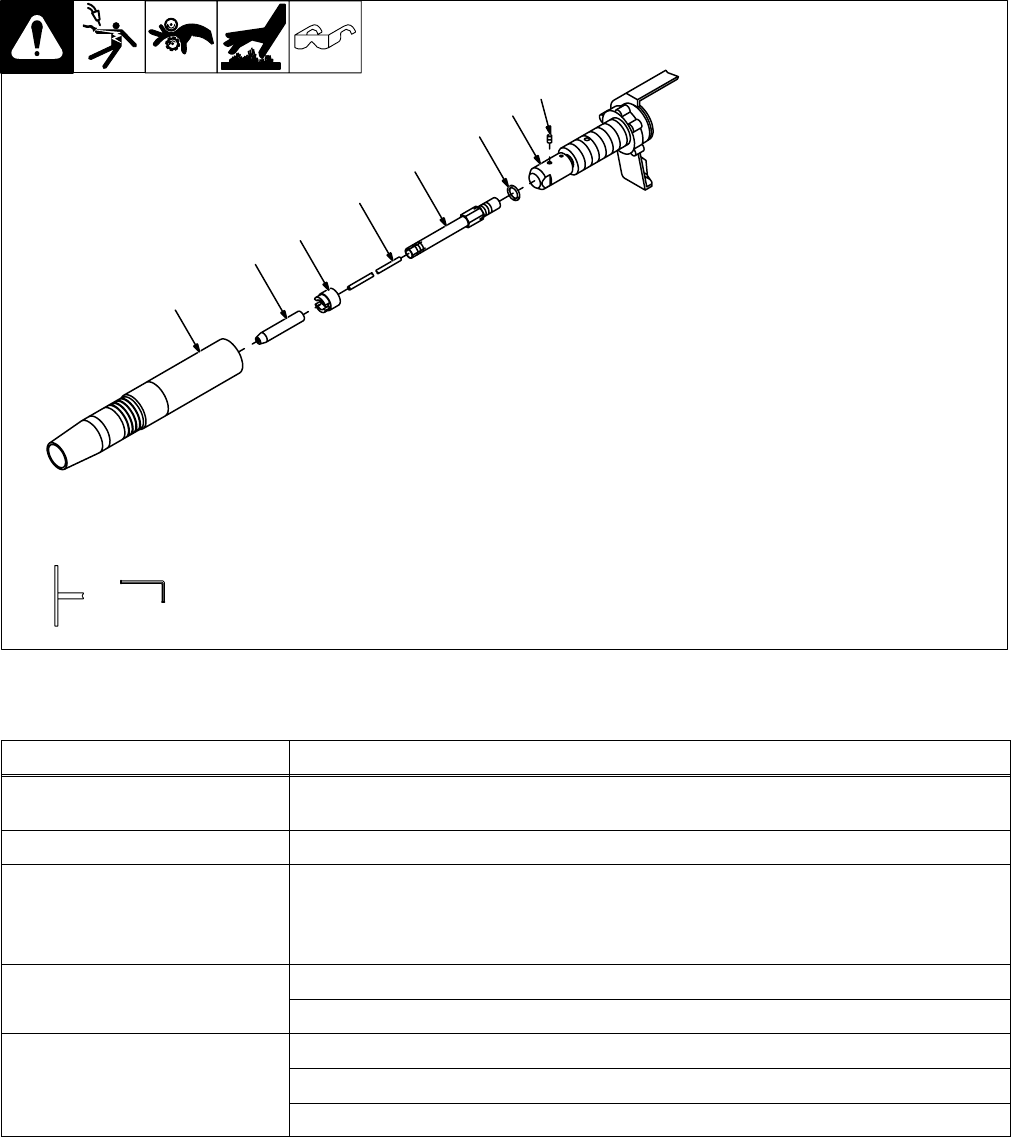

4-6. Replacing Contact Tip Adapter

150 430-B

1 Barrel Extension

Remove as shown.

2 Contact Tip

3 Compression Nut

To remove, see Section 4-2.

4 Liner

5 Contact Tip Adapter

6 O-Ring

7 Head Tube

8 Head Tube Setscrew

Loosen setscrews and remove

adapter.

Install new o-ring and adapter, and

tighten setscrews. Reinstall con-

tact tip, compression nut, and

nozzle.

Tools Needed:

3/32 in

1

2

3

4

5

6

7

8

4-7. Troubleshooting

Trouble Remedy

No weld output; gun/feeder does not

work.

Place Power switch on welding power source in the On position (see welding power source Owner’s

Manual).

Erratic weld output. Tighten and clean all connections.

Pressing gun/feeder trigger does not

energize weld control; welding wire is

not energized; shielding gas does not

flow.

Secure plug from gun/feeder trigger cord into 10-socket receptacle on weld control (see Section 2-6).

Wire feeds, shielding gas flows, but

ldi i i t i d

Secure control cable leads in welding power source (see welding power source Owner’s Manual).

welding wire is not energized.

See Troubleshooting section in welding power source Owner’s Manual.

Wire feeds erratically. Check and correct drive roll pressure (see Section 2-8).

Clean drive roll or replace drive roll (see Section 4-3).

Decrease spool brake pressure (see Section 2-8).