OM-950 Page 20

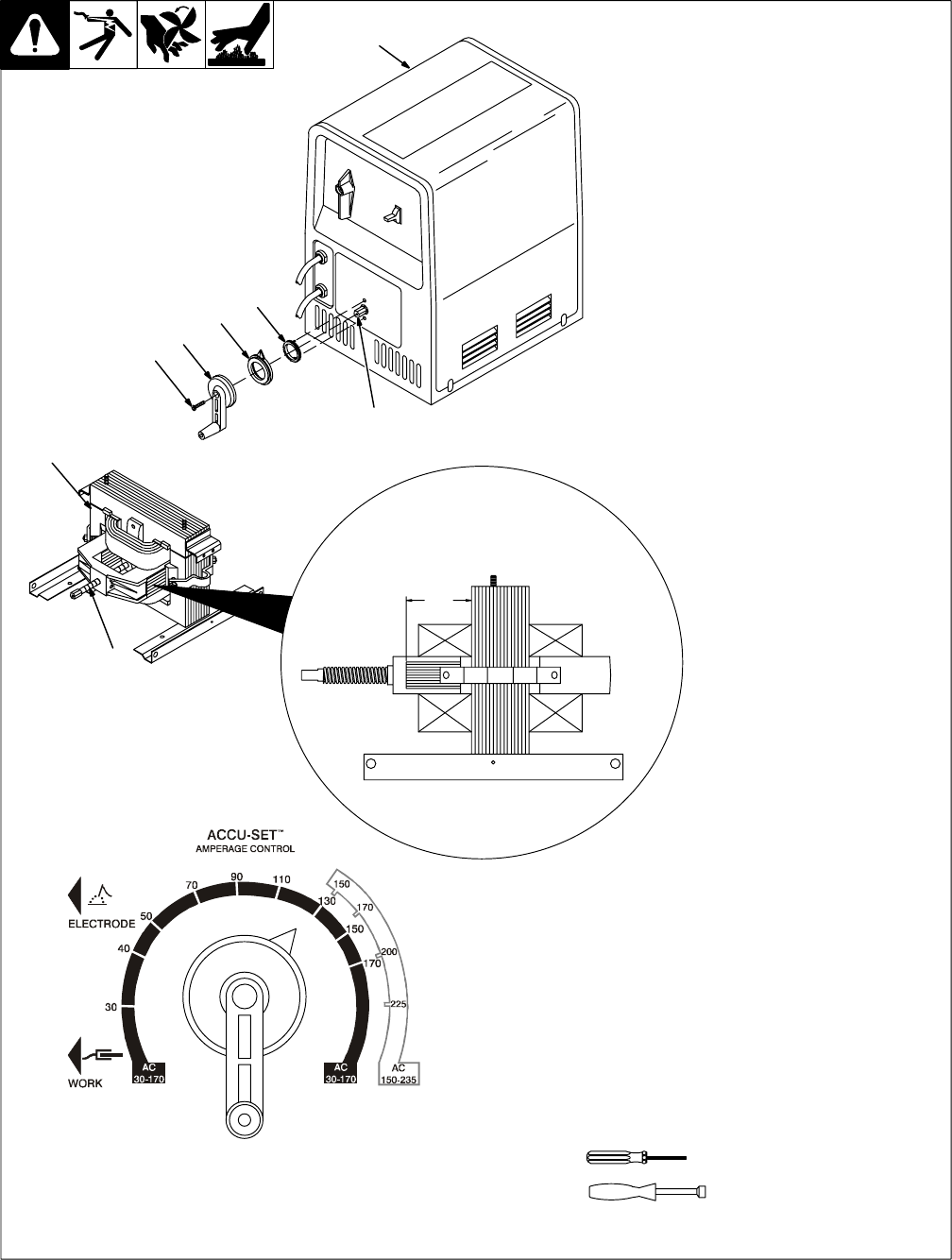

6-3. Reinstalling Amperage Adjustment Indicator

804 293-A / Ref. 802 248-D / Ref. 190 599-A

Y Turn Off welding power

source and disconnect input

power.

1 Wrapper

Remove wrapper from unit.

2 Crank Handle

3 Shunt Shaft

4 Transformer And Shunt

(Located Inside Unit)

Insert crank handle onto shunt

shaft protruding through front panel

and turn crank handle to adjust

shunt to the proper vale of “X”, de-

pending on model (see detail of

transformer and shunt.

Remove crank handle.

5 Pinion Gear

Install pinion gear onto front panel

making sure anti-rotation pins are in

holes on front panel.

6 Pointer Gear

Install pointer gear overtop of pinion

gear and rotate so pointer is indicat-

ing 130 Amps on ac Low Range

scale (see example).

Install crank handle overtop the sta-

tor/pinion gear assembly with the

handle straight down. It may be

necessary to turn the handle slight-

ly so vertical alignment is possible.

7 Securing Screw

Install securing screw through han-

dle, into threaded hole in shunt

shaft. Tighten securely.

Reinstall wrapper.

5/16, 3/8 in

4

3

Tools Needed:

X

For 225 A models, X = 2−1/2 in

Viewed from right side of unit.

Proper alignment of pointer and crank handle.

T-20 Torx

1

3

2

5

6

7