Manual de Instrucciones y Lista de Piezas HDS550

Lista De Repuestos

Puede escribirnos a:

Campbell Hausfeld

Attn: Parts Department

100 Production Drive

Harrison, OH 45030

Sirvase darnos la siguiente información:

- Número del modelo

- Código estampado en la unidad

- Descripción y número del repuesto según la lista de repuestos

1 Conjunto de boquilla de aire DH067300AV 1

2 Boquilla de líquido ▲ DH067400AV 1

3 Gatillo ● 1

4 Cuerpo de pistola no disponible 1

5 Empaque de válvula de aire ■ ◆ 2

6 Tuerca de empaque de válvula de aire ■ ◆ 1

7 Conjunto de vástago de válvula de aire ■ 1

8 Resorte de válvula de aire ■ 1

9 Entrada de aire ■ 1

10 Empaque de aguja de líquido ▲ ◆ 2

11 Tuerca de empaque ▲ 1

12 Tornillo de gatillo ● 1

14 Conjunto de aguja de líquido ▲ 1

15 Resorte de control de líquido ▲ 1

16 Perilla de control de líquido ▲ 1

17 Pasador del control de patrón ❍ 1

18 Arandela del control de patrón ❍ ◆ 1

19 Resorte del control de patrón ❍ 1

20 Aro de empaque del control de patrón ❍ ◆ 1

21 Empaque del control de patrón ❍ ◆ 1

No. Número

de del

Ref. Descripción Repuesto Ctd.

22 Tuerca del control de patrón ❍ 1

23 Perilla del control de patrón ❍ 1

24 Conjunto de tubo de material ❒ 1

25 Yugo ❒ 1

26 Palanca de regulación ❒ 1

27 Cubierta de taza ❒ 1

28 Tuerca ❒ 1

29 Empaquetadura (paquete de 3) DH067500AV 1

30 Bote DH067600AV 1

JUEGOS DE SERVICIO (contienen uno de cada componente,

salvo que se indique otra cantidad)

■ Juego de válvula de aire (cant. 2 – No. 5) DH550100AV

▲ Juego de control de líquido DH550200AV

(cant. 2 – No. 10)

❍ Conjunto de control de patrón DH550300AV

◆ Juego de empaquetaduras DH550400AV

(cant. 2 – No. 5 y No. 10)

● Juego de gatillo DH550500AV

❒ Conjunto de yugo DH550600AV

No. Número

de del

Ref. Descripción Repuesto Ctd.

22 Sp

3

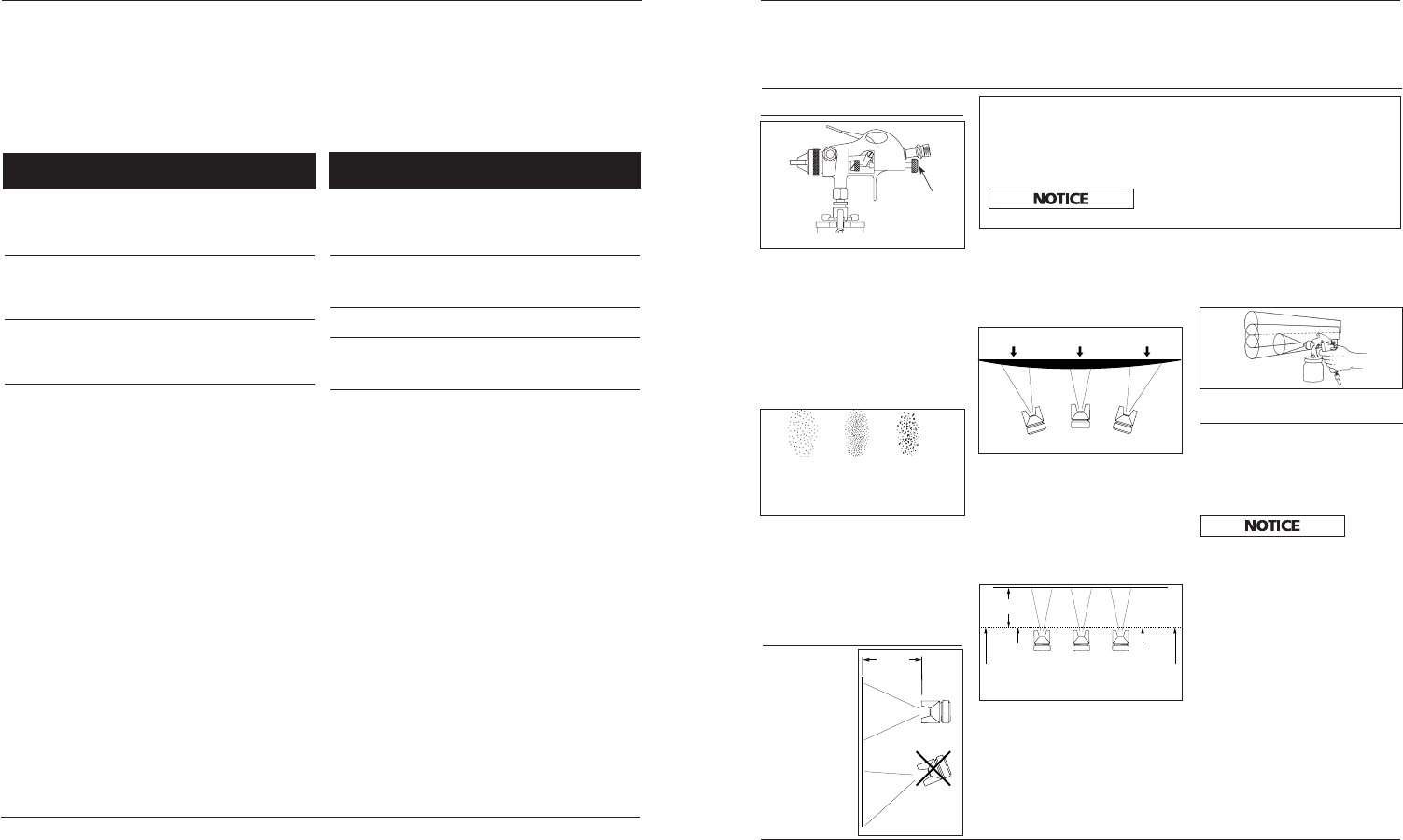

3. Trigger a short burst while turning

fluid control knob counterclockwise.

Observe the spray pattern on the tar-

get and adjust the fluid control knob

until the desired pattern (atomiza-

tion) is obtained.

If the spray is too fine (excessive over-

spray), caused by too much air for the

amount of paint being sprayed, reduce

the air pressure or open the fluid con-

trol to spray more material.

If the spray is too coarse (spitting globs),

reduce the amount of material with the

fluid control knob or thin the paint.

Before spraying the workpiece, practice

a few minutes on a cardboard target to

ensure the pattern size and consistency

are set correctly.

Operation

1. Begin spray-

ing. Always

keep the gun at

right angles to

the work. (See

Figure 4.)

Keep the nozzle

about 6 to 9 inches

from the work

surface through-

out the stroke

and always keep

the gun in motion

while spraying. Stopping gun movement

in mid-stroke will cause a build up of paint

and result in “runs.” Do not “fan” the gun

from side to side while painting. This will

cause a build-up of paint in the center of

the stroke and an insufficient coating at

each end (See Figure 5).

2. “Trigger” the gun properly. Start

the gun moving at the beginning

of the stroke BEFORE SQUEEZING

THE TRIGGER and release the trigger

BEFORE STOPPING GUN MOVEMENT

at the end of the stroke. This pro-

cedure will “feather” (blend) each

stroke with the next without show-

ing overlap or unevenness).

3. The amount of paint being applied

can be varied by the speed of the

stroke, distance from the surface and

adjustment of the fluid control knob.

4. Overlap strokes just enough to

obtain an even coat. NOTE: Two

thin coats of paint will yield better

results and have less chance of runs

than one heavy layer.

5. Use a piece of cardboard as a shield

to catch overspray at the edges of

the work to protect other surfaces.

Use masking tape to cover other

areas if needed.

Maintenance

DAILY CLEAN-UP

Local codes may require specific clean-

ing methods and equipment. Follow

local codes and manufacturer’s recom-

mendations for the use and disposal of

spray materials and solvent.

Clean

spray gun

immediately after use. Paint and other

material dry quickly in the small pas-

sages rendering gun useless due to the

difficulty of removing hardened paint

from the passages inside the gun.

NOTE: In the instructions below, the

use of the word “solvent” refers to the

specific solvent for the material used (eg:

lacquer thinner for lacquer, etc ).

1. Remove and empty the canister; then

rinse with a solvent recommended

for the paint or other material used.

2. Refill canister with clean solvent

and attach to the gun. Spray solvent

through the gun while shaking the

gun vigorously. Wipe the gun exteri-

or with a solvent soaked rag. Repeat

until the gun is clean.

WATER/OIL IN COMPRESSED AIR

All compressor pumps discharge some condensed water, oil or contaminates with

the compressed air.

IMPORTANT: This condensation will cause “fish eyes” to appear in the paint

job. Install appropriate water/oil removal equipment and controls as necessary

for the intended application.

Failure to install appropriate water/oil removal

equipment may result in damage to machinery

or workpiece.

Operating Instructions and Parts Manual HDS550

6 - 9”

Figure 4

Thin coat Thin coat

Heavy coat

Figure 5

INCORRECT

Correct

Paint too

coarse

Paint too

fine

Figure 3 - Pattern Consistency

(Atomization)

6 - 9”

Pull

Trigger

Start

Stroke

Release

Trigger

End

Stroke

Figure 6

Figure 7

Preparation (Cont.)

Figure 2 - Adjustment on Spray Gun

Fluid Control

Knob