DRIVE SECTION

M30

ADJUSTABLE CLUTCH

33

CLUTCH ADJUSTMENT

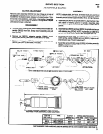

Remove clutch assembly (36310) from tool. Place pin in hole of

jaw (36318) or wrench on square end of spindle (36311) to adjust

nut (36313). To adjust properly, release nut to least tension. Tight-

en nut one or two positions -each click = one position. Assemble

clutch to tool and test torque on fastener to be tightened. Repeat

until desired torque is obtained.

DISASSEMBLY

ASSEMBLY

NOTE: Lubricate balls, jaw faces, bit holder shaft, pins and thrust

pad with ARO 40036-1 grease when assembling clutch. Clutch

assembly should contain approximately 1/8 oz. (3.5 g) of grease.

a. Assemble jaw (40772) to spindle (36311) aligning face of jaw

with center of bearing groove in spindle. Assemble balls

(Y16-203) into groove and slide jaw ahead to retain balls in

groove.

a. Remove clutch housing (left hand threads) and bit holder as-

b.

sembly (36322) from tool. Grasp clutch assembly and pull

Assemble key (36319) and jaw (36318) to spindle and secure

from gearing.

with retaining ring (37243). NOTE: Assemble jaw (36318) to

spindle with small hole in face of jaw facing jaw (40772).

b. Remove nut (36313) releasing washer (33609) clutch

spring, pad (36316) pins (36317) and balls (Y16-205).

c. Assemble balls (Y16-205), pins (36317) thrust pad (36316)

clutch spring, washer (33609) and nut (36313). Adjust to de-

c. Remove retaining ring (37243) releasing jaw (36318) key

sired tension (see “Clutch Adjustment”).

(36319) jaw (40772) and balls (Y 16-203).

d. Assemble spring (31092) plug (31093) bit holder assembly

(36322) and bit to spindle and assemble to tool. Assemble

clutch housing to tool.

BALL (16) Y 16-203

“O” RING Y 325-8

SPRING

31092,

7

@PIN (6) 36317

NUT 36313

q

BALL Yl6-205

\

(6) 7

WASHER

336091

THRUST PLUG 310933

RETAINING RING 37243

BIT 30320-2

JAW 8 BIT HOLDER

ASS’Y 36322

/

GUIDE ADAPTER IS PRESSED

INTO HOUSING

SEE PAGE 14 FOR ADDlTlONAL GUIDE ADAPTERS

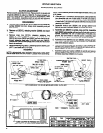

CLUTCH

TYPE

CLUTCH

ASS’Y. NO.

SPRING IDENTIFICATION

SPRING NO. TYPE WIRE WIRE THICKNESS

38310-l

HIGH TORQUE

37872

FLAT

.093” x .188”

38310

MED. TORQUE

36315

FLAT

.062” x .156”

3831 o-2

LOW TORQUE

38512 ROUND

.080” DIAMETER

PARTS

MARKED

THUS

q

ARE

INCLUDED

IN SERVICE KIT NO. 42114 AND/OR

42341, SEE PAGE 12.

5