M35

41

MAINTENANCE SECTION

Always wear eye protection when operating or

performing maintenance on this tool.

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting any

accessory on this tool, or before performing any

maintenance on this tool.

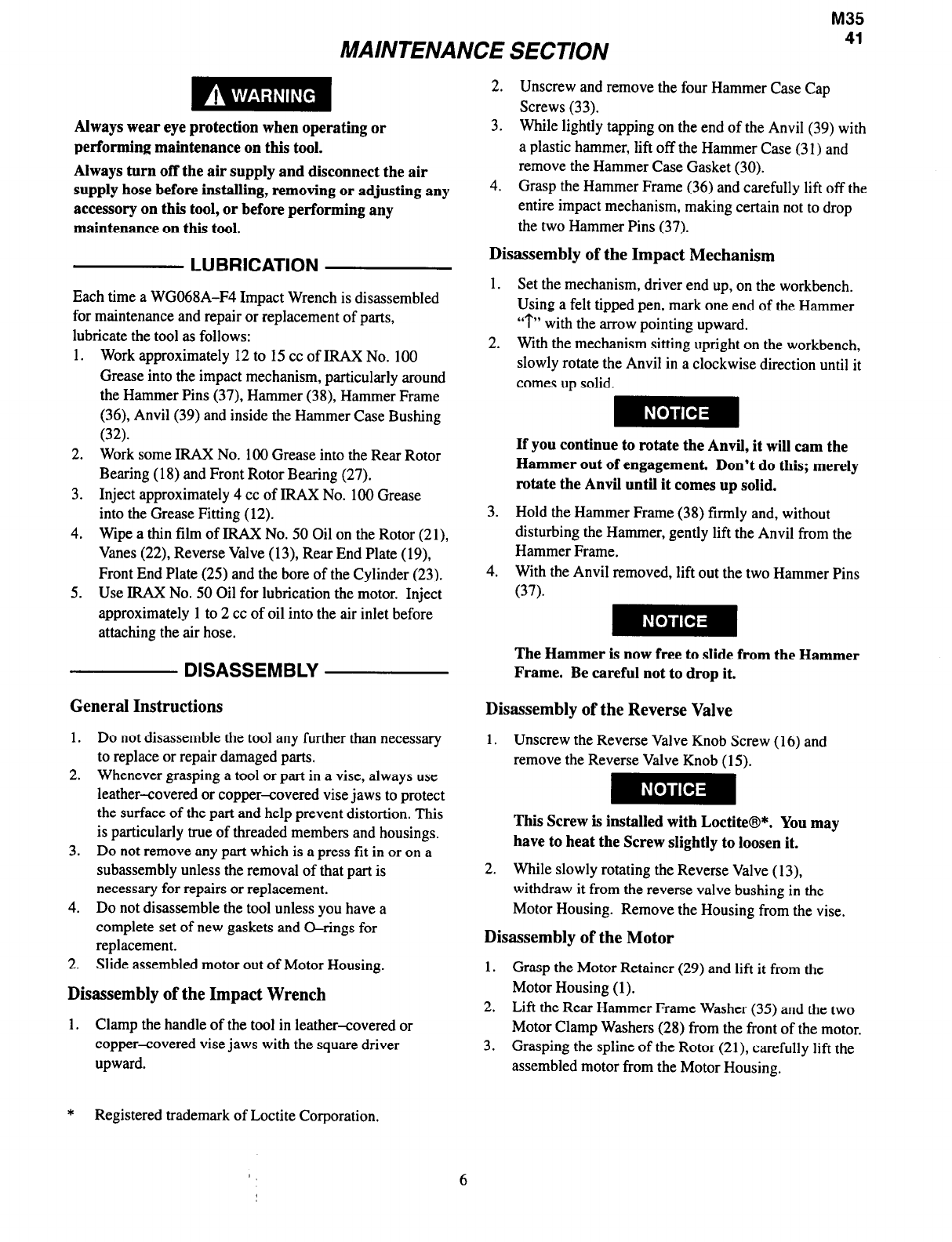

LUBRICATION

Each time a WG068A-F4 Impact Wrench is disassembled

for maintenance and repair or replacement of parts,

lubricate the tool as follows:

1.

2.

3.

4.

5.

Work approximately 12 to 15 cc of IRAX No. 100

Grease into the impact mechanism, particularly around

the Hammer Pins (37), Hammer (38), Hammer Frame

(36), Anvil (39) and inside the Hammer Case Bushing

(32).

Work some IRAX No. 100 Grease into the Rear Rotor

Bearing (18) and Front Rotor Bearing (27).

Inject approximately 4 cc of IRAX No. 100 Grease

into the Grease Fitting (12).

Wipe a thin film of IRAX No. 50 Oil on the Rotor (2 1),

Vanes (22), Reverse Valve (13), Rear End Plate (19),

Front End Plate (25) and the bore of the Cylinder (23).

Use IRAX No. 50 Oil for lubrication the motor. Inject

approximately 1 to 2 cc of oil into the air inlet before

attaching the air hose.

DISASSEMBLY

The Hammer is now free to slide from the Hammer

Frame. Be careful not to drop it.

General Instructions

Disassembly of the Reverse Valve

1.

2.

3.

4.

2.

Do not disassemble the tool any further than necessary

to replace or repair damaged parts.

Whenever grasping a tool or part in a vise, always use

leather-covered or copper-covered vise jaws to protect

the surface of the part and help prevent distortion. This

is particularly true of threaded members and housings.

Do not remove any part which is a press lit in or on a

subassembly unless the removal of that part is

necessary for repairs or replacement.

Do not disassemble the tool unless you have a

complete set of new gaskets and G-rings for

replacement.

Slide assembled motor out of Motor Housing.

Disassembly of the Impact Wrench

1. Clamp the handle of the tool in leather-covered or

copper-covered vise jaws with the square driver

upward.

2. Unscrew and remove the four Hammer Case Cap

Screws (33).

3. While lightly tapping on the end of the Anvil (39) with

a plastic hammer, lift off the Hammer Case (3 1) and

remove the Hammer Case Gasket (30).

4. Grasp the Hammer Frame (36) and carefully lift off the

entire impact mechanism, making certain not to drop

the two Hammer Pins (37).

Disassembly of the Impact Mechanism

1. Set the mechanism, driver end up, on the workbench.

Using a felt tipped pen, mark one end of the Hammer

“?” with the arrow pointing upward.

2. With the mechanism sitting upright on the workbench,

slowly rotate the Anvil in a clockwise direction until it

comes up solid.

If you continue to rotate the Anvil, it will cam the

Hammer out of engagement. Don’t do this; merely

rotate the Anvil until it comes up solid.

3. Hold the Hammer Frame (38) firmly and, without

disturbing the Hammer, gently lift the Anvil from the

Hammer Frame.

4. With the Anvil removed, lift out the two Hammer Pins

(37).

1. Unscrew the Reverse Valve Knob Screw (16) and

remove the Reverse Valve Knob (15).

This Screw is installed with LoctiteB*. You may

have to heat the Screw slightly to loosen it.

2. While slowly rotating the Reverse Valve (13),

withdraw it from the reverse valve bushing in the

Motor Housing. Remove the Housing from the vise.

Disassembly of the Motor

1. Grasp the Motor Retainer (29) and lift it from the

Motor Housing (1).

2. Lift the Rear Hammer Frame Washer (35) and the two

Motor Clamp Washers (28) from the front of the motor.

3. Grasping the spline of the Rotor (21), carefully lift the

assembled motor from the Motor Housing.

* Registered trademark of Loctite Corporation.