Unpacking and Clean-Up

1. Finish removing the shipping crate.

2. Remove the skid from under the press.

3. Remove the protective coating from all rust

protected surfaces with a soft cloth moistened

with kerosene or a mild solvent. Do not use

acetone, gasoline, or paint thinner. These will

damage painted surfaces.

4. To prevent rust, apply a thin coat of paste wax to

the table.

Installation

The drill press must be located in a dry, well lighted

area with adequate room on all sides of the

machine. The floor must be level and the drill press

must rest solidly on the floor. The most accurate

and vibration free operation will require the drill

press to be bolted to the floor. While this is not

absolutely necessary, it is highly recommended.

Place shims near the three bolt holes to level the

drill press, if necessary. Equal pressure should be

applied to all three nutswhen tightening to prevent

distorting the base.

Raising the Head

The drill press head is lowered on the column for

crating and transportation. Before operating the drill

press, the head will need to be raised to the

operational level. To raise the head:

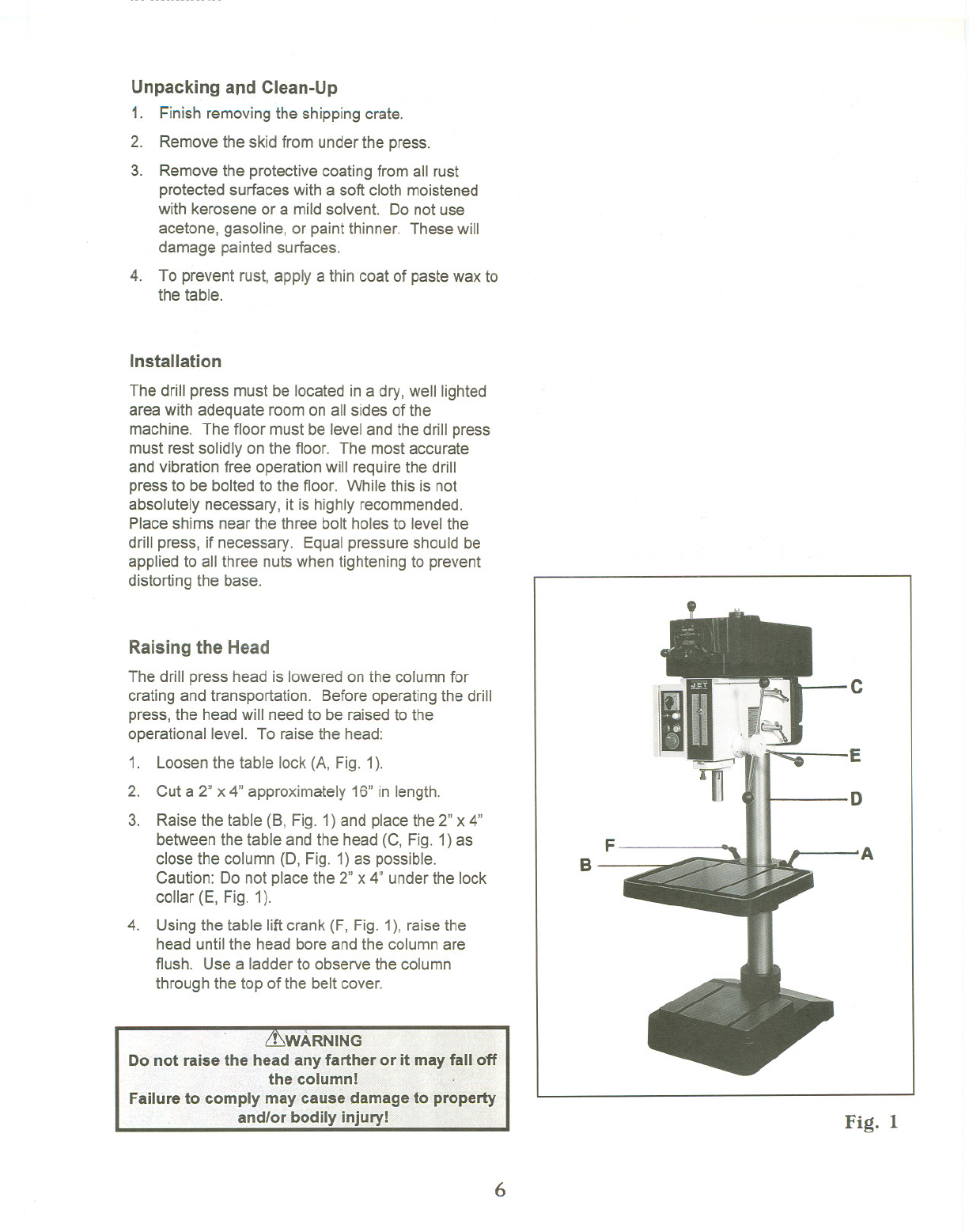

1. Loosen the table lock (A, Fig. 1).

2. Cut a 2" x 4" approximately 16" in length.

3. Raise the table (B, Fig. 1) and place the 2" x 4"

between the table and the head (C, Fig. 1) as

close the column (D, Fig. 1)as possible.

Caution: Do not place the 2" x 4" under the lock

collar (E, Fig. 1).

4. Using the table lift crank (F, Fig. 1), raisethe

head until the head bore and the column are

flush. Use a ladder to observe the column

through the top of the belt cover.

Failure to co

6

B

F

A

c

E

D

Fig. 1