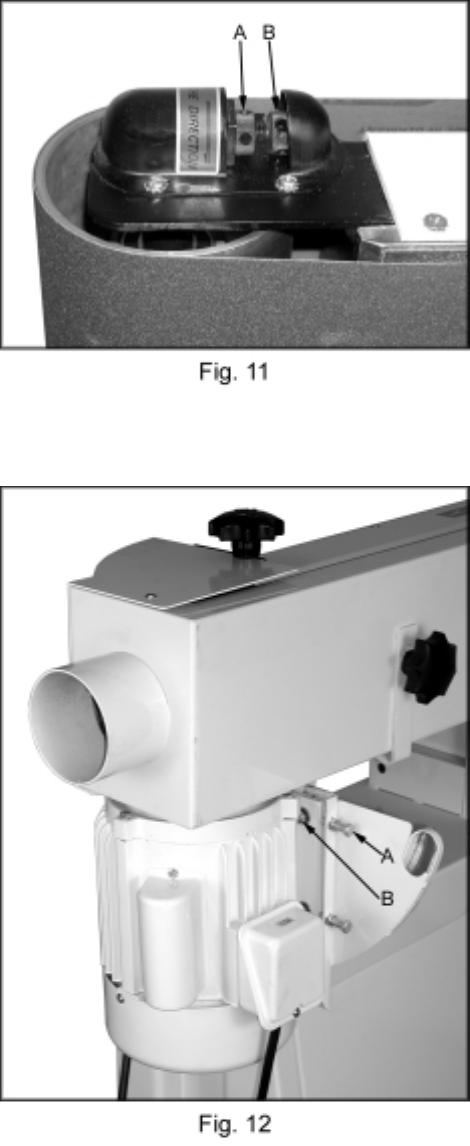

12

3. Insert the driver with the round shaft,

supplied with the machine into the micro

adjusting nut (A, Fig. 11) and turn away

from you to loosen.

4. Turn the micro adjusting screw (B, Fig. 11)

in ¼ turn increments until the belt tracks

evenly on the rollers when rotated by hand.

5. Tighten the micro adjusting nut (A, Fig. 11).

6. Connect the machine to power.

7. Turn on the power to the machine just

enough to start the belt rotating and then

turn off. Do this several times and observe

belt tracking. Adjust as necessary. If the

tracking cannot be corrected goto the next

section “Motor Mount Tracking Adjustment”.

Motor Mount Tracking Adjustment

The EHVS-80CS comes with tracking

adjustment bolts (A, Fig. 12) on the motor

plate. These are set at the factory and should

not require any further adjustment. If, however,

you are not able to track the belt using the belt

tracking adjustment assembly on the sanding

platen, the motor mount bolts will have to be

adjusted:

1. Disconnect the machine from the power

source.

2. Slightly loosen the four motor mount nuts

(B, Fig. 12) just enough so the tracking bolts

can make an adjustment.

3. Loosen both locking hex nuts.

4. Turn one bolt (A, Fig. 12) a ¼ turn and

rotate the sanding belt by hand to observe

which direction the belt is tracking. If it is

traveling in the direction needed to correctly

track the belt, tighten both locking nuts and

fine tune the tracking with the belt tracking

assembly on the platen.

5. If the belt starts to travel in the wrong

direction, back off a quarter turn and tighten

the other bolt a quarter turn. This should

start the belt in the proper direction.

Note: Use the motor mount bolts as a “major”

tracking adjustment. Use the belt tracking

assembly on the sanding plates as a “fine”

tracking adjustment.