14

Material chips or shavings are the best indicator

of proper blade speed and downfeed rate. The

ideal chip is thin, tightly curled and warm to the

touch. Chips that range from golden brown to

black indicate excessive force. Blue chips

indicate extreme heat from too high a blade

speed, which will shorten blade life. Thin or

powdered chips indicate insufficient downfeed

rate.

Blade Guides

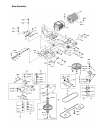

Loosen the handle (Figure 17) and slide the

guide assembly as close to the workpiece as

possible. This will prevent excessive exposure

of the blade during operation.

[NOTE: The handle (Figure 17) can be adjusted

out of the way. Lift up on the handle and rotate it

on the pin. Release the handle, making sure it

seats itself properly on the pin.]

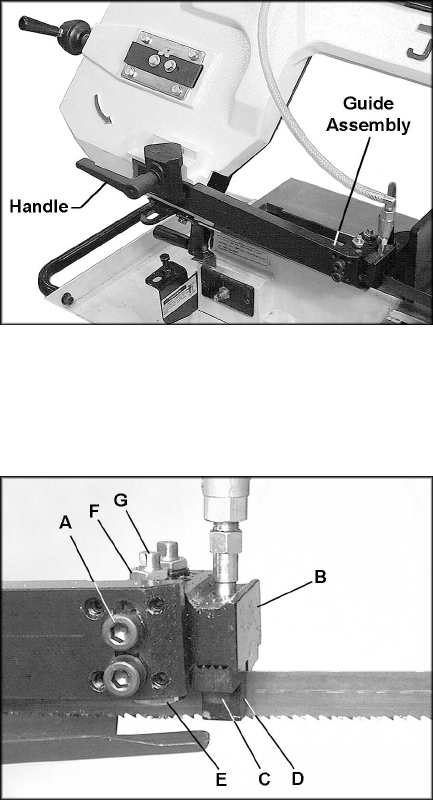

The guide bearings and carbide guide blocks

come pre-adjusted from the factory, but should

be inspected frequently and adjustments made

as needed. For most efficient operation and

maximum accuracy, provide 0.001” clearance

between the blade and the guide bearings. The

bearings will still turn freely with this clearance.

If the clearance is incorrect, the blade may track

off the drive wheel.

1. Disconnect machine from power source.

2. Loosen the two socket head cap screws (A,

Figure 18) and move the guide seat (B,

Figure 18) up or down until the guide blocks

(D, Figure 18) are positioned adequately

across the width of the blade.

3. Loosen the socket head cap screws (C,

Figure 18) on the carbide guide blocks (D,

Figure 18) and shift both guide blocks until

they place a light pressure on the blade. Re-

tighten the socket head cap screws (C,

Figure 18).

4. The outer guide bearing (E, Figure 18) is

mounted to an eccentric bushing and is

adjustable. Loosen the hex nut (F, Figure

18) and rotate the bearing shaft (G, Figure

18) with a wrench until the bearing (E,

Figure 18) clears the blade by

approximately .001”. Do not pinch the blade.

5. Re-tighten hex nut (F, Figure 18).

6. Repeat these steps for the other blade

guide assembly.

Figure 17

Figure 18