1

5

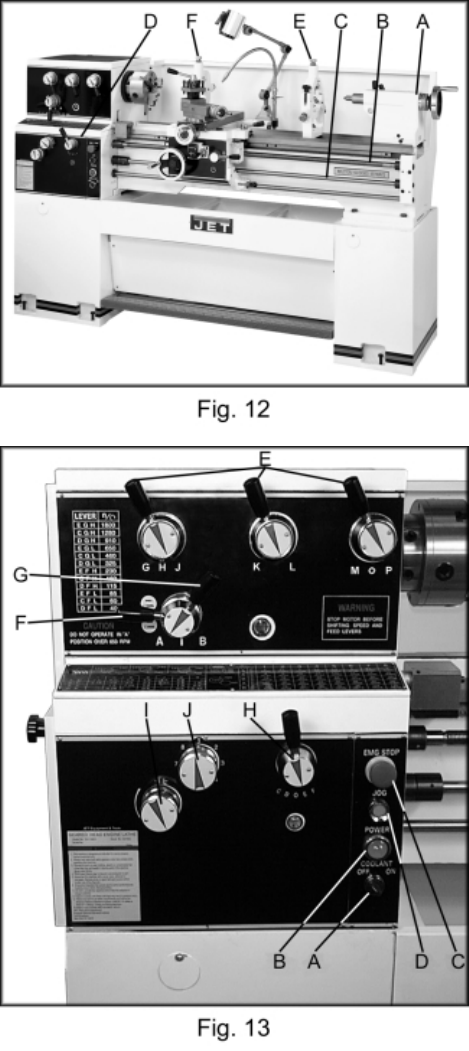

Follow Rest

The traveling follow rest (F, Fig. 12) is

mounted on the saddle and follows the

movement of the turning tool. Only two fingers

are required as the place of the third is taken

by the turning tool. The follow rest is used for

tuning operations on long, slender workpieces.

It prevents flexing of the workpiece from the

pressure of the cutting tool.

The sliding fingers are set similar to the steady

rest, free of play, but not binding. Always

lubricate with Mobil DTE Oil Heavy Medium.

Controls

1. Control Panel - located on front of

gearbox.

A. Coolant On-Off Switch (A, Fig. 13) -

turns coolant pump on and off.

B. Power Indicator Light (B, Fig. 13) - lit

whenever lathe has power.

C. Emergency Stop Switch (C,Fig.13)

- depress to stop all machine

functions.

Caution: lathe will still have power.

Twist to re-set.

D. Jog Switch (D, Fig. 13) - depress and

release to advance spindle

momentarily.

2. Headstock Gear Change Levers

(E, Fig. 13) - located on front of the

headstock. Move levers according to

speed chart for desired setting.

3. Leadscrew/Feed Rod Directional Lever

(F, Fig. 13) - located on front of headstock.

Moving the lever up causes carriage travel

toward the tailstock. Moving the lever

down causes carriage travel toward the

headstock. When chuck is spinning in the

forward or counter-clockwise direction.

Do not move lever while machine is

running.

4. Feed/Lead Selector Lever (G, Fig. 13) -

located on the front of the headstock.

Used whenever setting up for threading or

feeding.

Caution: in the "A" position, never run the

lathe higher than 650 RPM.