7

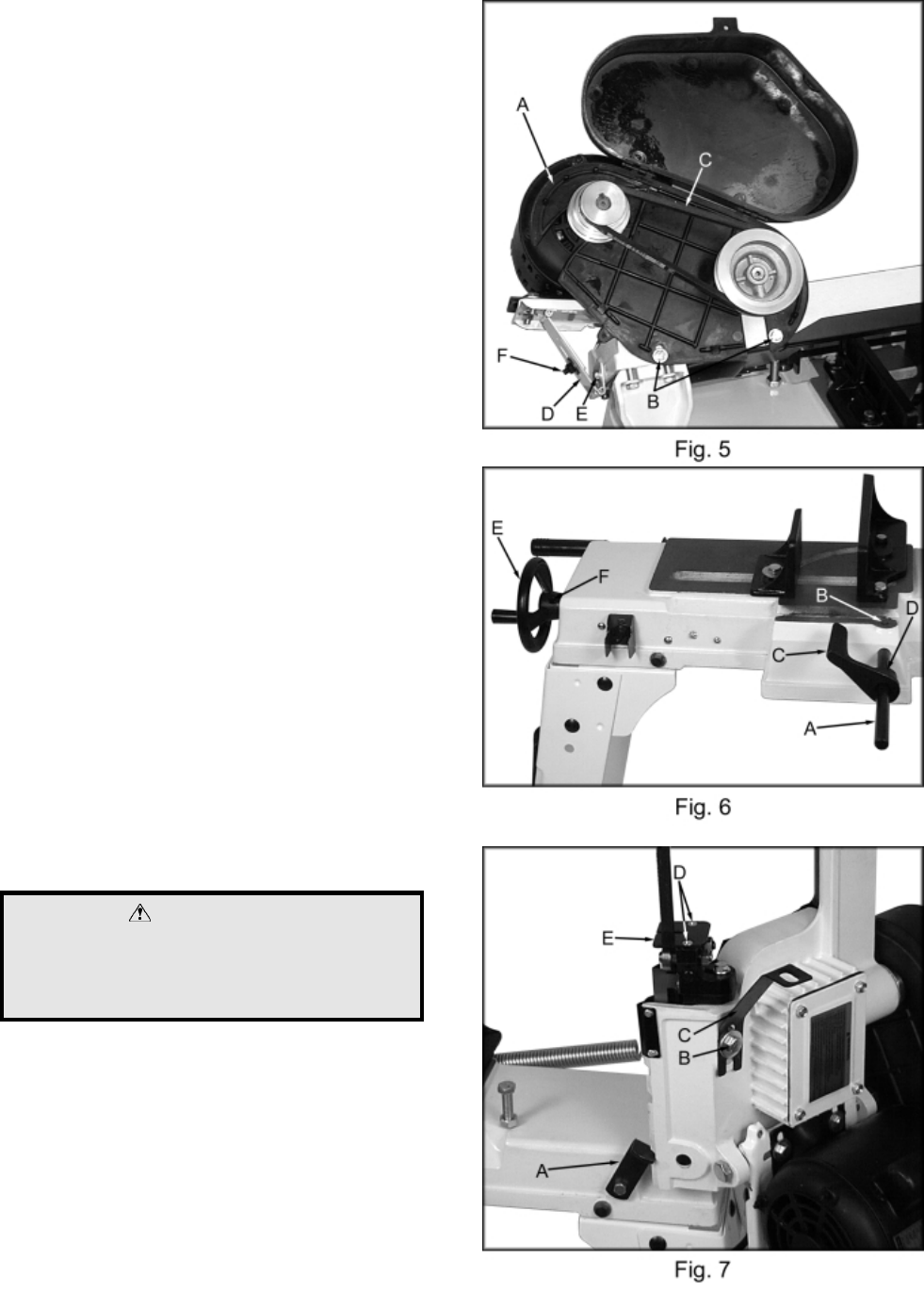

11. Slide pulley cover (A, Fig. 5) around motor

shaft and worm gear shaft. Secure with two

hex cap screws and washers (B, Fig. 5).

12. Lift motor with one hand while the other

hand places V-belt (C, Fig.5) on both pulleys.

13. Attach the tension bracket (D, Fig. 5) to the

saw bow with one 5/16”x3/4” hex head bolt

and flat washer (E, Fig. 5).

14. Connect the two tension brackets with one

5/16”x3/4” carriage bolt, one 5/16” flat

washers and one 5/16” hex nut (F, Fig. 5).

Hint: Insert the carriage bolt from the inside

so the hex nut is easy to access with a

wrench.

15. Tension belt by pressing down on the motor

while tightening hex nut (F, Fig. 5) until

finger pressure on the belt between the two

pulleys causes approximately 1/2" deflection.

Close pulley cover. Don’t over tighten the

belt.

16. Insert stop rod (A, Fig. 6) into bed and

tighten set screw (B, Fig. 6). Slide stock

stop (C, Fig. 6) onto rod and tighten set

screw (D, Fig. 6) to hold in place.

17. Slide handwheel (E, Fig. 6) onto shaft and

secure by tightening set screw (F, Fig. 6).

Make sure set screw seats on flat portion of

shaft.

Vertical Cutting Plate Assembly

Note: These steps are only necessary when

using the bandsaw in the vertical mode.

WARNING

Disconnect the bandsaw from the power

source before making any repairs or

adjustments!

Failure to comply may cause serious injury!

1. Disconnect the bandsaw from the power

source.

2. Raise the arm to the vertical position and

lock in place with lever (A, Fig. 7).

3. Loosen bolt (B, Fig. 7) and insert bracket (C,

Fig. 7). Tighten bolt just enough to hold the

bracket in place.