12

Assembly of JWBS-14CS

Tools Required for Assembly

Metric combination wrench set and

adjustable wrench

#1 and #2 cross point screwdrivers

Exposed metal surfaces, such as the table, have

been given a protective coating. This should be

cleaned with a soft cloth and solvent, such as

kerosene. Do not use an abrasive pad, and do

not get solvents on plastic parts.

1. Remove pulley cover from inside of stand.

2. Place cabinet stand upright on a level

surface. If desired, the stand can be further

stabilized by securing it to the floor with lag

screws through the inside corner holes. If

using a mobile base, lock the casters before

assembling or operating the band saw.

Saw body is heavy! Use

caution when lifting and stabilize until firmly

attached to the stand! Failure to comply may

cause serious injury!

3. With the aid of a second person, lift the saw

body out of the shipping container and place

onto stand top. Be sure front of saw (with

JET logo) faces stand front (JET logo).

4. Line up holes in saw body with holes in top

of stand. Fasten saw body to the stand with

four M8 x 40 hex cap screws, eight M8

washers, four M8 lock washers, and four

M8 hex nuts (as shown in item A, page 8).

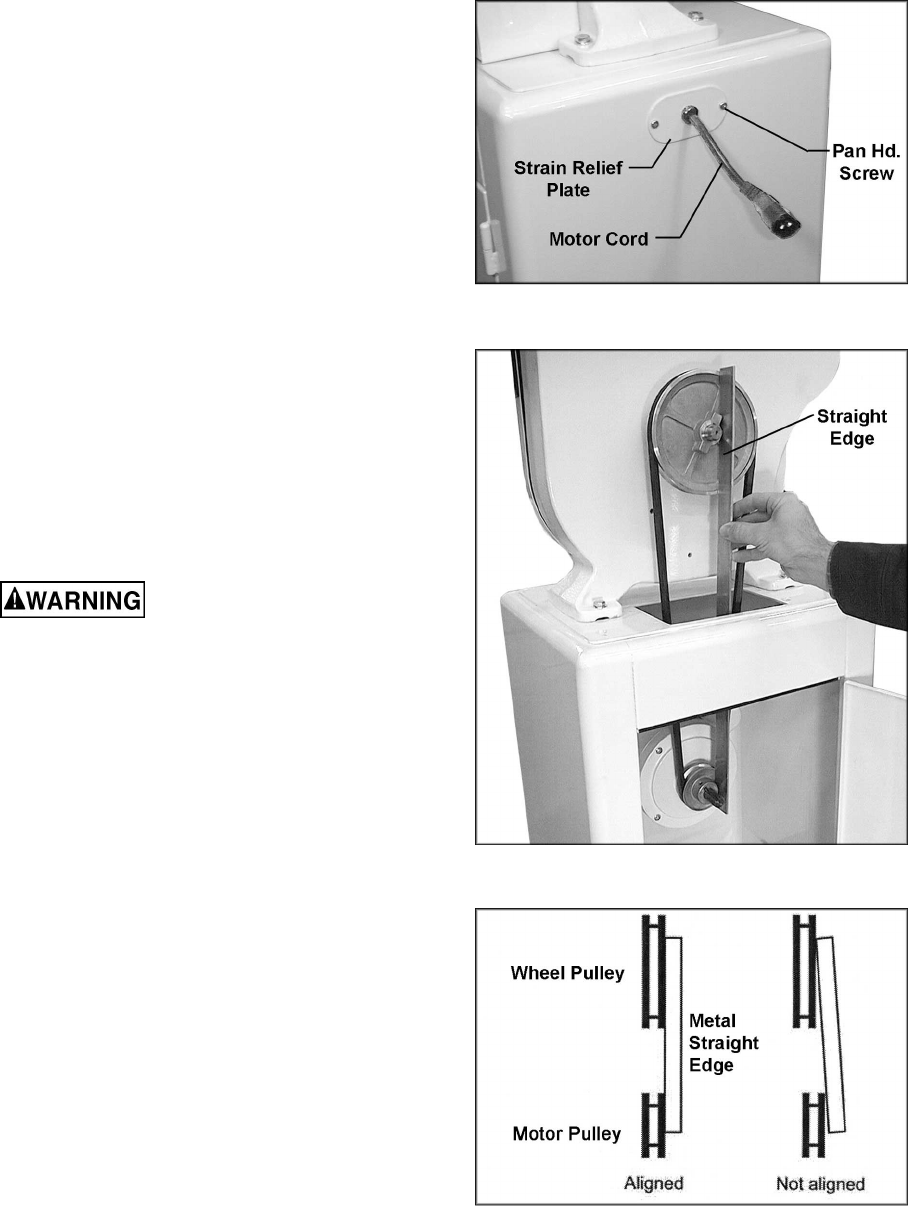

5. Push motor cord and strain relief plate

through the opening in the side of the stand

(Fig. 12). Fasten the strain relief plate to the

stand with two M5 x 12 pan head machine

screws (shown in item B, page 8).

6. Check the alignment of the pulleys by

placing a straight edge against the flat sides

of the motor and wheel pulleys (Figure 13).

If the pulleys lie in a straight plane (Figure

14) they are aligned. If they do not lie in a

straight plane, loosen the set screw on one

of the pulleys and shift the pulley in or out

until both pulleys lie in a straight plane.

Tighten set screw.

Figure 12

Figure 13

Figure 14