17

5. Loosen jam nut and turn table stop (Figure

2

6) left or right to raise or lower the stop.

Tighten jam nut to hold table stop in place.

6. Unlock table, tilt back onto table rest and

confirm table is 90 degrees with the blade.

7. If necessary, adjust scale pointer to zero.

Changing Blades

Blade teeth are sharp! Use

care when handling the saw blade. Failure to

comply may cause serious injury.

1. Disconnect machine from power source.

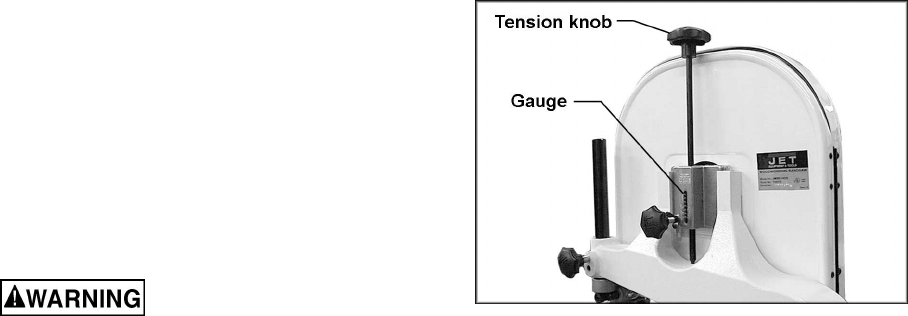

2. Loosen blade tension by turning the

tension knob counterclockwise (Figure 28).

3. Remove the table insert and the table pin.

4. Open both wheel covers.

5. Remove the blade from between upper

and lower blade guides. Remove blade

from upper and lower wheels. Turn blade

to direct through slot in table.

6. Guide new blade through table slot. Place

b

lade in upper and lower blade guides.

Note: The blade teeth should face the

operator, and they should point down

toward the table.

7. Place blade in the middle of the upper and

lower wheel.

8. Re-install table insert and table pin.

9. Tension and track blade before operating

saw. Find instructions for tensioning and

tracking the blade under "Adjusting Blade

Tension" and "Adjusting Blade Tracking".

Adjusting Blade Tension

1. Disconnect machine from power source.

2. Turn blade tension knob (Figure 28)

clockwise to tension blade. A gauge on the

upper wheel slide bracket indicates the

approximate tension according to the width

of the blade. Initially, set the blade tension

to correspond to the blade width as marked

on the gauge.

Figure 28