4b) Start button

4c) Emergency/off knob

4d) Speed regulator

6) Bearing block

7) Machine bed

8) Transportation wheel

9) Machine stand

10) Locking lever

11) Quick change vice

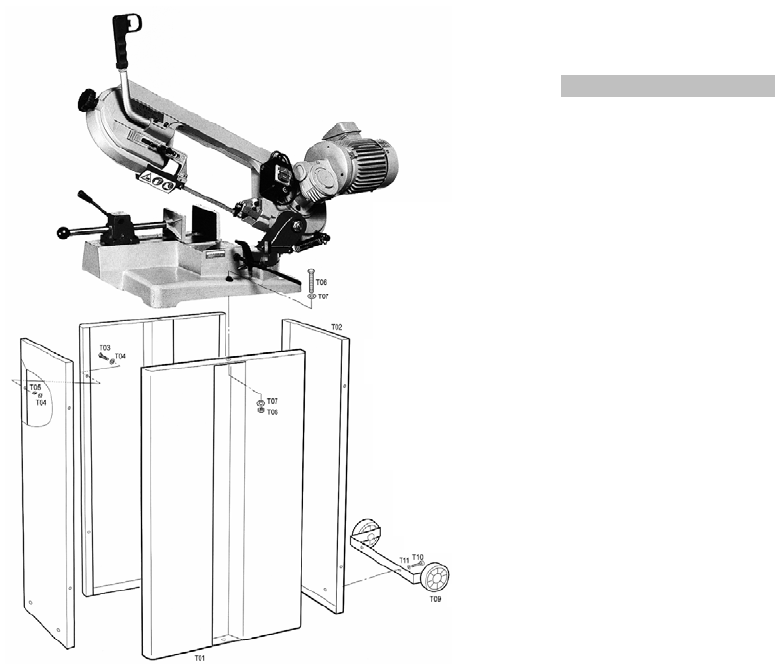

Assembling the machine

Fig 2

1. Screw the 4 side panels together.

2. Screw the machine to the stand.

3. Attach the transportation wheels to the stand.

4. The machine is now assembled.

Cleaning and lubricating the new machine

The smooth surfaces of the machine are covered in a

viscous grease to prevent corrosion during transportation.

All traces of this grease must be removed before the

machine is put into operation. This is best done using either

petroleum or white spirits.

Note: Do not use paint thinners or similar, as this would

damage the machine’s paintwork.

Make sure that no solvents or grease come into contact with

the rubber or plastic parts.

After cleaning, coat all the smooth parts with a film of

medium-viscose oil, article no. 100385.

PREPARING FOR USE

Check all the individual parts of the machine before putting it

into operation to ensure that they are in perfect condition and

fully functioning. Once all the appropriate safety measures

are in place and provided the machine is used appropriately,

its precision can be guaranteed for a long time to come.

6 Setting up the machine

Maintenance and transportation

1. The machine is not positioned levelly on your site.

Before transporting/moving the machine, ensure that the

chosen lifting/carrying points will allow stable transportation.

2. If the machine is to be transported/moved using a forklift

or stacker, this must be done slowly and with the greatest

care. Risk of tipping!

Information on using the machine

- Only one person is required to operate the machine.

- In order to ensure that the machine is safe to operate, it

should be run through its individual functions without being

put into operation.

- Before starting to saw, make sure that the workpiece is

secured firmly in the vice and that its end section is

supported appropriately.

- Only use saw blades of a size that correspond to those in

the following table.

- Contact the dealer before undertaking any maintenance

work on this machine.

MINIMUM REQUIREMENTS FOR THE MACHINE

ENVIRONMENT

- Mains voltage and frequency must be appropriate to the

motor.

- The ambient temperature should be between –10° and

+50°.

- The relative humidity must never exceed 90°.

USING THE BAND SAW

6