- 12

Note

Only trained personnel is permitted to add

motor, gear and pump oil.

Note

Align the appliance horizontally prior to

check the oil level in order not to get a false

result.

Check the oil prior to starting the appliance

or at least 5 minutes after switching off the

engine.

Caution

Increased risk of fire! When filling the motor

oil make sure that no oil lands on hot motor

surfaces.

Î

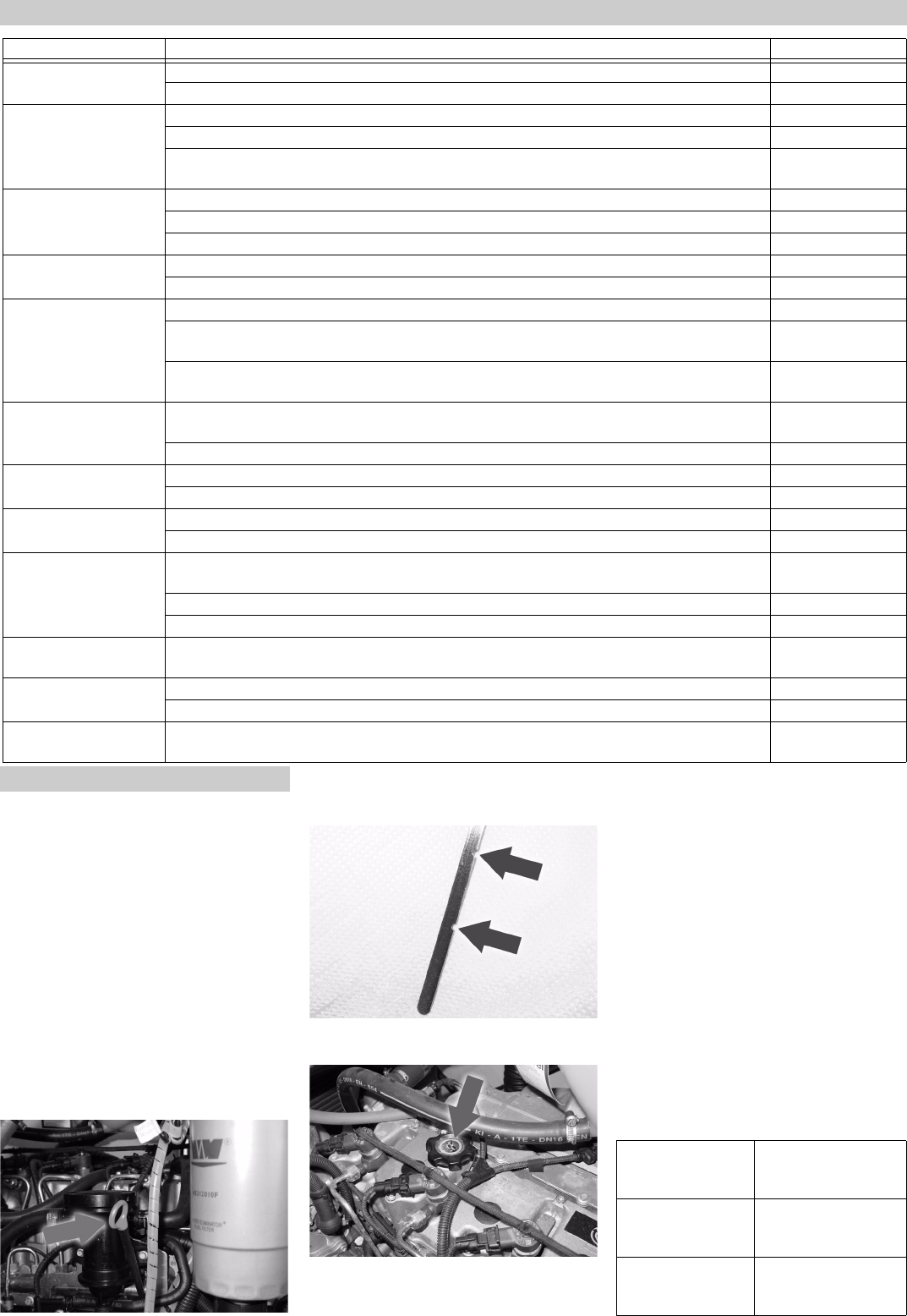

Remove the oil dip, wipe it and reinsert it.

Î Remove the oil dip one more time and

check the oil level.

The oil level is correct if it is within the mark-

ings (arrows) on the oil dip.

Î If the oil level is below the bottom mark,

open the filler neck lid (arrow) and add

fresh motor oil.

Î Wait five minutes, until the oil has col-

lected in the oil pan.

Î Check the oil level as described above.

Î Repeat this procedure as often as nec-

essary until the oil level is between the

markings on the oil dip.

Î After the check, insert the oil dip and

close the lid of the filler neck.

Note

Only trained personnel is permitted to add

motor, gear and pump oil.

Note

Replace the oil while the motor has operat-

ing temperature. Align the appliance hori-

zontally prior to the oil change.

Motor

Maintenance intervals

Time Activity By whom

Prior to each drive Check the lighting. Operator

Check the tyre pressure and their state. Operator

Every 10 operating

hours or daily

Check oil level in the pump gear (see "Initial startup"), refill oil if needed. Operator

Check the water filter and clean if necessary. Operator

Check coolant level in the equalisation container (see "Initial startup"), refill coolant if need-

ed.

Operator

Once after the first 50

operating hours

Replace motor oil (see "Maintenance Procedures"). Customer Service

Replace oil filter insert on motor. Customer Service

Check the screw connections on the motor. Call customer service if necessary. Customer Service

Once after the first 150

operating hours

Replace oil in the pump gear. Customer Service

Replace oil in the intermediate gear. Customer Service

Every 50 operating

hours or weekly

Check pipes to see if there are any leaks. Operator

Check the V-belt tension, retension if necessary (see "Maintenance Procedures"). Customer Service/

Operator

Check hoses for wear, replace if required. Customer Service/

Operator

Every 100 operating

hours

Check/clean the air filter insert (see "Maintenance Procedures"). Operator

Check the screw connections on the motor. Call customer service if necessary. Customer Service

Every 200 operating

hours

Replace motor oil (see "Maintenance Procedures"). Customer Service

Replace oil filter insert on motor. Customer Service

Every 400 operating

hours

Replace the fuel filter. Customer Service

Cleaning the water separator. Customer Service

After 750 operating

hours or once a year

Lubricate the brake on the drawbar (see "Maintenance Procedures"). Operator

Replace air filter insert (see "Maintenance Procedures"). Customer Service

Replace V-belt. Customer Service

Every 1500 operating

hours

Check the injection pressure at the fuel injector nozzle. Customer Service

Every 3000 operating

hours

Replace oil in the pump gear. Customer Service

Replace oil in the intermediate gear. Customer Service

Every other year Check the coolant in the motor and replace (see "Maintenance Procedures"). Customer Service/

Operator

Maintenance Works

Check the oil level on the motor and add

motor oil

Oil change (to be performed by custom-

er service only)

Above 25 °C SAE30 or

SAE10W-30

SAE 15W-40

0 °C to 25 °C SAE20 or

SAE10W-30

SAE 15W-40

Below 0 °C SAE10W or

SAE10W-30

SAE15W-40

14 EN