- 6

Caution

Do not completely deplete the fuel in the

fuel tank, otherwise, the fuel system will

have to be ventilated. Possibly suctioned

dirt from the bottom of the tank can lead to

malfunctions.

Î Check the fill level of the diesel fuel at

the bar segment display for the fuel lev-

el. If required, top off the diesel fuel.

For temperatures below 0°, only use

winter diesel.

Î Check the fill level of the water at the

bar segment display for the water level

in the tank. Top off the water tank if nec-

essary. Connect the water supply hose

to the water inlet.

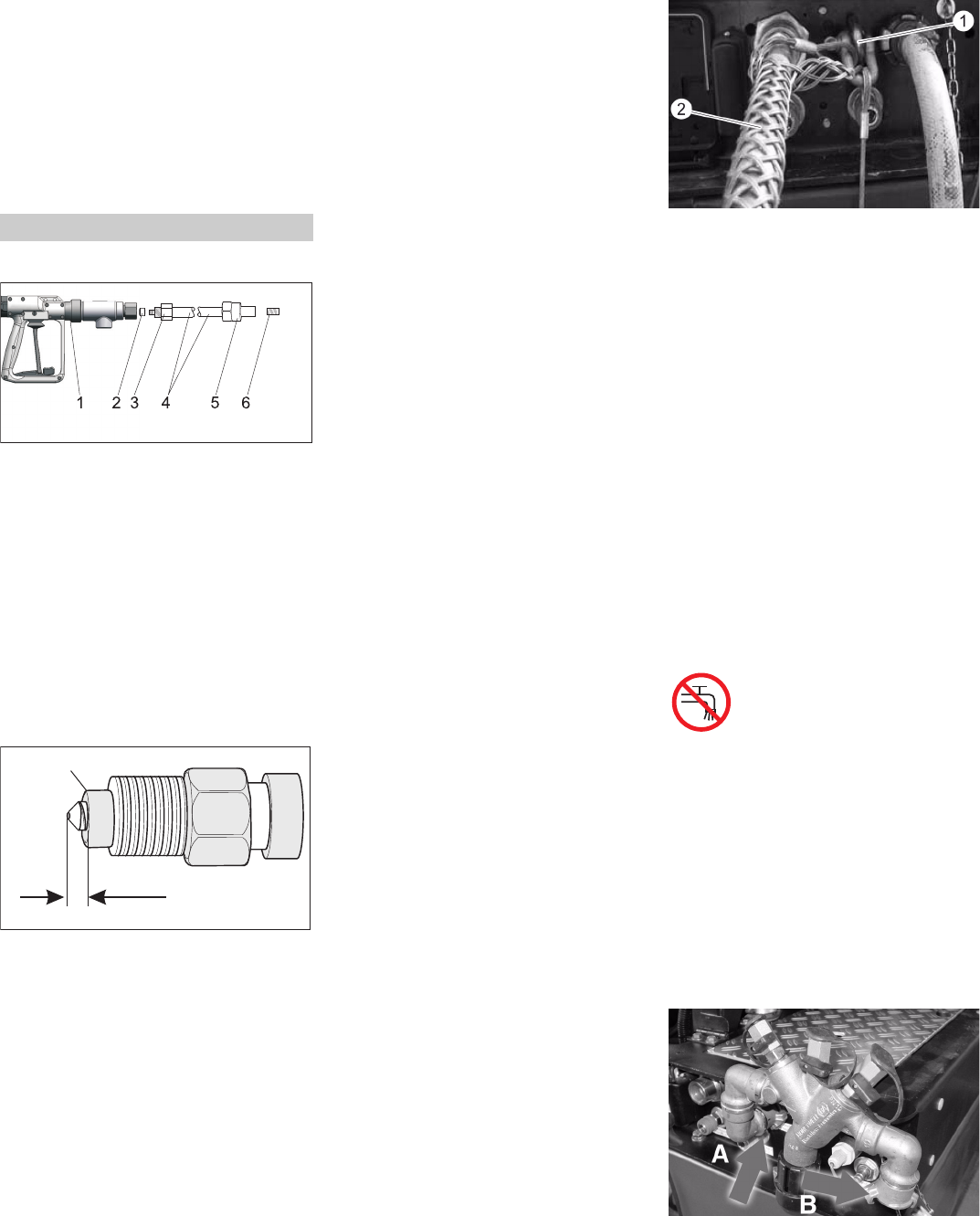

1 Trigger gun

2 Pressure ring

3 Pressure screw

4 Spray lance

5 Nozzle holder

6 High pressure nozzle

Î Remove the protective caps on the

spray pipe.

Î Grease the thread on the gun side with

stainless steel screw grease (6.280-

180.0).

Î Screw the pressure ring onto the spray

pipe.

Î The sealing cone of the spray pipe must

protrude about 1-1.5 thread lengths (B)

from the pressure ring (A).

Î Rotate the pressure ring (A) by hand to

adjust the distance (left thread).

Î Insert the spray pipe all the way into the

gun.

Î

Secure the spray pipe by tightening the

pressure screw (torque approx. 100 Nm).

Do not perform this procedure until after the

unit has been ventilated, see "Ventilating

the high pressure system“.

Î Grease the thread on the nozzle side

with stainless steel screw grease

(6.280-180.0).

Î Grease the nozzle holder with stainless

steel screw grease (6.280-180.0) and

screw it onto the spray pipe (left

thread).

Î Grease the thread of the high pressure

nozzle with stainless steel screw

grease (6.280-180.0) and screw it onto

the nozzle holder (hexagon socket).

ƽ Danger

Risk of injury from leaks or water jets

emerging from leaks.

– Hoses, pipes and the spray unit must

be in good condition and installed prop-

erly.

– Check the high pressure hose daily.

– Only use original high pressure hoses

that are approved for the respective

pressure range and temperature.

– Avoid contact with chemicals.

– Do not use hoses with kinks.

– Do not use the high pressure hose any-

more if the thread is damaged or cor-

roded.

– Stop using the high pressure hose if the

external wire layer is visible.

– Do not route the high pressure hose

across sharp edges.

– Lay the high pressure hoses in such a

way that no vehicle can drive over it.

– Do not use high-pressure hoses that

have been driven over, kinked, pressed

or bent even if there is no externally vis-

ible damage.

– Completely lay out the high pressure

hose, do not overlap.

–

High pressure hoses age with time. Re-

place high pressure hoses every 6

years, even if they are in good condition.

– High pressure hoses that have been

stored for more than 2 years, may no

longer be used.

– Store the high pressure hose so that

there is no mechanical strain. Store in a

cool, dry and dustfree place.

– Do not stretch the high pressure hose

during storage, as the high pressure

hose might change its length during op-

eration.

– Relieve tension from the high pressure

hose after operation, purge excess wa-

ter, coil it and store it properly.

Î Unscrew the protective caps from the

high pressure connection of the hand

spray gun and pull off at the high pres-

sure hose.

Î Clean the thread and grease it with

stainless steel screw grease (6.280-

180.0).

Î Check the high pressure hose for flaw-

less condition (no damage). Only use

intact hoses.

Î Connect the high pressure hose to the

hand spray gun (procedure as de-

scribed in Chapter "Connecting the

spray pipe to the gun").

Î Remove the protective cap from the

high pressure outlet of the appliance.

Î Clean the thread and grease it with

stainless steel screw grease (6.280-

180.0).

Î Connect the high pressure hose to high

pressure connection (procedure as de-

scribed in Chapter "Connecting the

spray pipe to the gun").

1 Hose sock mounting

2 Hose sock

Î When using a hose sock to protect the

high pressure hose from ripping off,

hook the hose sock into the hose sock

mount.

Î Roll the control line off the winch to

hose length. Make sure that the control

line is not underneath the high pressure

hose, as the high pressure hose can

rub against it and cause a line break.

Î Pull of the protective cap or antifreeze

plug on the appliance connection side.

Î Connect the short cable end of the

winch with the socket.

Î

Plug the protective caps together to pre-

vent soiling of the protective cap insides.

Î Connect the control line on the gun side

and plug the protective caps together.

According to the applicable regu-

lations, the appliance must never

be used on the drinking water net

without a system separator. Use a

suitable system separator manufactured by

Kärcher; or, as an alternative, a system

separator as per EN 12729 Type BA.

Note

Water with drinking water quality with a

pressure between 0.15 and 0.6 MPa (1.5 to

6 bar) is required to ensure a smooth oper-

ation of the system.

Î Remove the protective cap from the wa-

ter supply inlet of the appliance.

Î Connect the system separator to the

water inlet (option).

A If the system separator was installed,

the water inlet is on the appliance

B Water inlet on the system separator

Check the fill level in the water tank

Start up

Connecting the spray pipe to the gun

Connecting the nozzle

B

A

Connect the high pressure hose to the

gun and the appliance.

Connect the control line

Connect the water supply

8 EN