- 13

Pump and gear

Î The oil level is correct if it is within the

markings on the oil dip.

Î After the check, insert the oil dip and

close the lid of the filler neck.

Note

Prior to every operation, the fill level of the

coolant in the equalisation container must

be checked.

Caution

Observe the brand of antifreeze used. The

mixture can cause a chemcial reaction and

hazardous substances can be generated.

Do not mix different antifreeze types.

ṇ Warning

The motor can overheat if there is a lack of

coolant. Turn the motor off immediately and

let it cool down.

If the motor is so overheated, that water va-

pors escape, immediately turn the motor off

and keep a safety distance to the motor un-

til the pressure has decreased.

Danger of burns! Never open the lid on the

cooler while the motor has operating tem-

perature. The container is under pressure.

Î Open the lid on the equalisation con-

tainer of the motor coolant, fill in fresh

clean water and the required antifreeze.

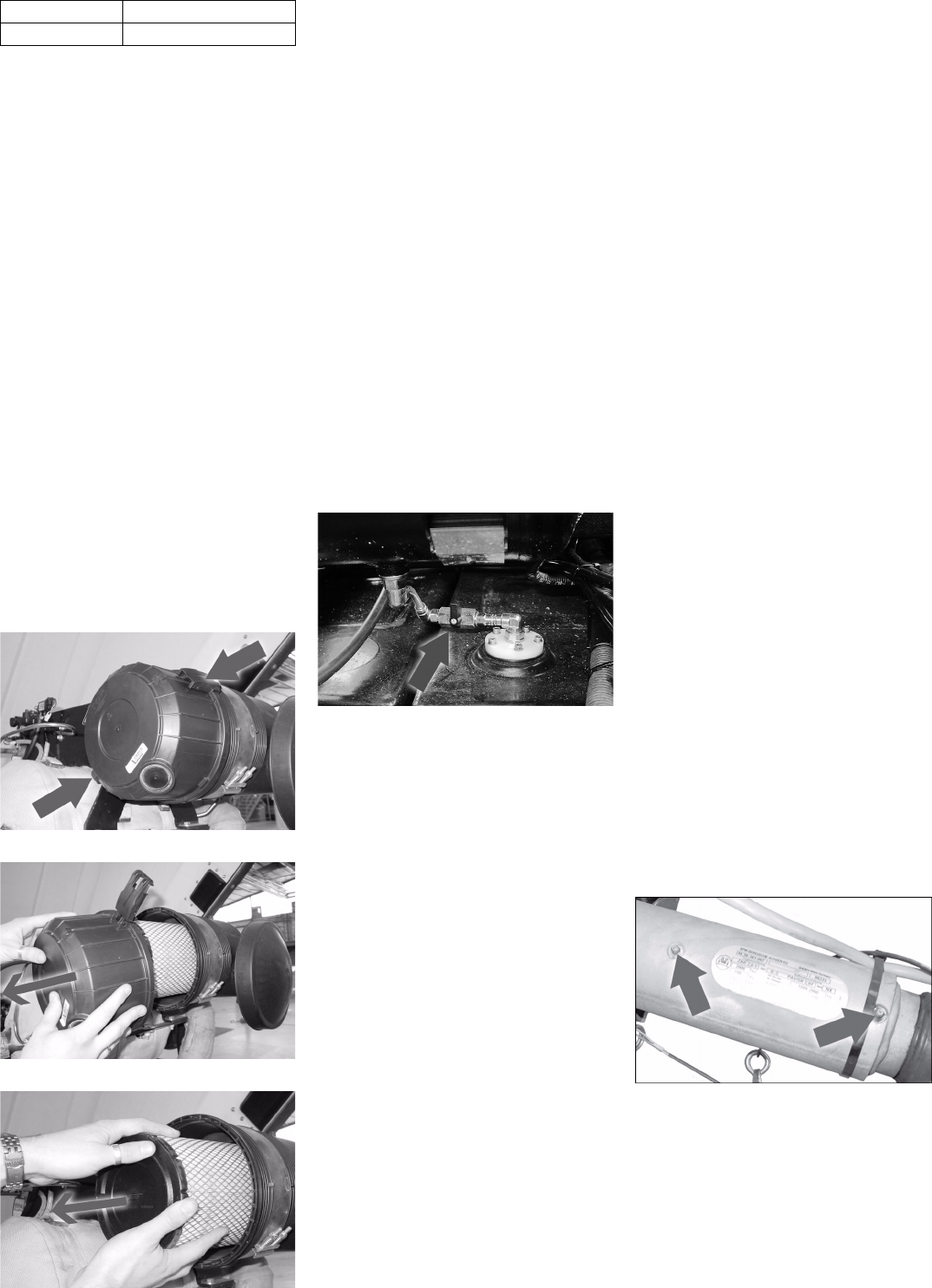

Î Open both locks (arrows) on the lid.

Î Remove the lid and the dust sediments.

Î Take out the filter inlay.

Î Blow out the filter insert with com-

pressed air (max. 2 bar) from the inside.

Î Clean the inside of the air filter housing

with a cloth.

Note

Severely contaminated or defective filter in-

serts must always be replaced.

Î Please the filter insert into the air filter

housing with the closed side facing out.

Note

Make sure the lid fights snugly, if the lid

does not close properly, dust can get into

the combustion chamber of the motor and

damage it.

Î Replace the lid and close the locks.

Note

The compressed air system must be

drained in regular intervals.

During continuous operation, it might be

necessary to drain it 2 to 3 times a day.

Note

Do not drain the liquid from the system dur-

ing high pressure operation. If the ball tap is

open, pressure cannot be built up in the

compressed air lines.

Î Open the ball tap. Allow the water to

drain.

Î After the drain procedure, close the ball

tap.

Note

Maintenance work on the compressor may

only be performed by the authorised cus-

tomer service.

ṇ Warning

Battery acid is very corrosive! Always wear

acid-resistant goggles, gloves and an

apron when working with battery acid.

Never charge the battery in the vicinity of

open flames or igniting sparks.

The battery may only be charged in rooms

that are sufficiently ventilated.

Depending on the battery type, the acid lev-

el might need to be checked.

The motor must be turned off to charge the

battery.

Note

Prior to connecting the charger, the con-

necting cables to the control must be dis-

connected from the battery. Otherwise, the

control could be damaged!

If the appliance is not used for an extended

period and if there is frost, remove the bat-

tery and store it in a location protected from

frost.

ṇ Warning

Never connect frozen batteries to charge

them. Risk of explosion!

Prior to charging, thaw the battery and

warm to at least 16 °C.

Note

When disconnecting the battery, first dis-

connect the negative and then the positive

terminal.

When reconnecting the battery, first con-

nect the positive and then the negative ca-

ble.

Do not transpose the connecting cable.

Risk of cable fire!

Î Disconnect the connecting cable from

the battery at the negative terminal.

Î Disconnect the connecting cable from

the battery at the positive terminal.

Î Connect the charger.

Î Disconnect the charger after the charg-

ing process is complete.

Î Connect the connecting cable to the

positive terminal on the battery.

Î Connect the connecting cable to the

negative terminal on the battery.

Note

If the V-belt is not sufficiently tensioned,

this can cause an overheating of the motor

or to an insufficient battery charge.

Î Shut off the motor and remove the key

from the key switch.

Î To check whether the V-belt is ten-

sioned, press the belt with your thumb.

If the V-belt can easily be deflected, or if it

sits loosely on the pulleys, you must order

authorised customer service to tension/re-

place the V-belt.

Note

Defective V-belts must be replaced imme-

diately.

Caution

The V-belt must only be tensioned or re-

placed by Customer Service.

Î Press lubricant into both lubrication nip-

ples (arrows) using a commercial

grease press.

Pump Mobil D.T.E Oil AA 320

Gear Mobil D.T.E Oil AA 320

Check the coolant and refill

Cleaning/replacing the air filter

Draining the compressed air system

Compressor

Charge/replace battery

Checking the V-Belt

Lubricate the brake on the drawbar

15EN