18

Check to ensure there are no parts of the flat-head screws

raised above the vertical table work surface. Edges of the screws protruding

above the work surface could damage workpieces or cause irregular cuts.

BLADE GUIDE BEARING ADJUSTMENT

The proper alignment of the blade guide bearings is the most important adjustment

on the metal cutting band saw. The blade guide bearings are adjusted and tested

before the band saw leaves the factory. The need for further adjustment will be

unnecessary if the band saw is used and maintained properly. Should the blade

guide bearing get out of adjustment, it is important they be re-adjusted immediate-

ly. If the blade guide bearings are out of adjustment, the blade will not cut straight.

If the problem is not immediately corrected, damage to the blade will occur.

Blade guide bearing adjustment is a critical adjustment to

the metal cutting band saw. Before attempting to correct the blade guide bear-

ing adjustment, try installing a new band saw blade. This could correct the poor

performance. If a new blade becomes dull on one side sooner than the other, it

will start cutting crooked. Simply changing the blade should correct this prob-

lem whereas the more difficult blade guide bearing adjustment will not.

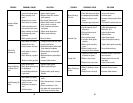

If a new blade does not correct the cutting

problem, check the blade guides for

proper spacing. See Figure 6.

1. Ensure there is 0.001" clearance

between the 0.025" blade thickness and

the guide bearings.

2. The inner guide bearing is fixed and

cannot be adjusted.

3. The outer guide bearing is mounted to

an eccentric bolt and can be adjusted.

4. Loosen the nut while holding the bolt

with a wrench.

5. Position the eccentric bolt by turning it

to the desired clearance. Check this

clearance with a thickness gauge.

6. Securely tighten the nut.

7. Repeat steps 4 through 6 to adjust the

second blade guide bearing.

8. The back edge of the band saw blade should

just barely touch the guide bearing.

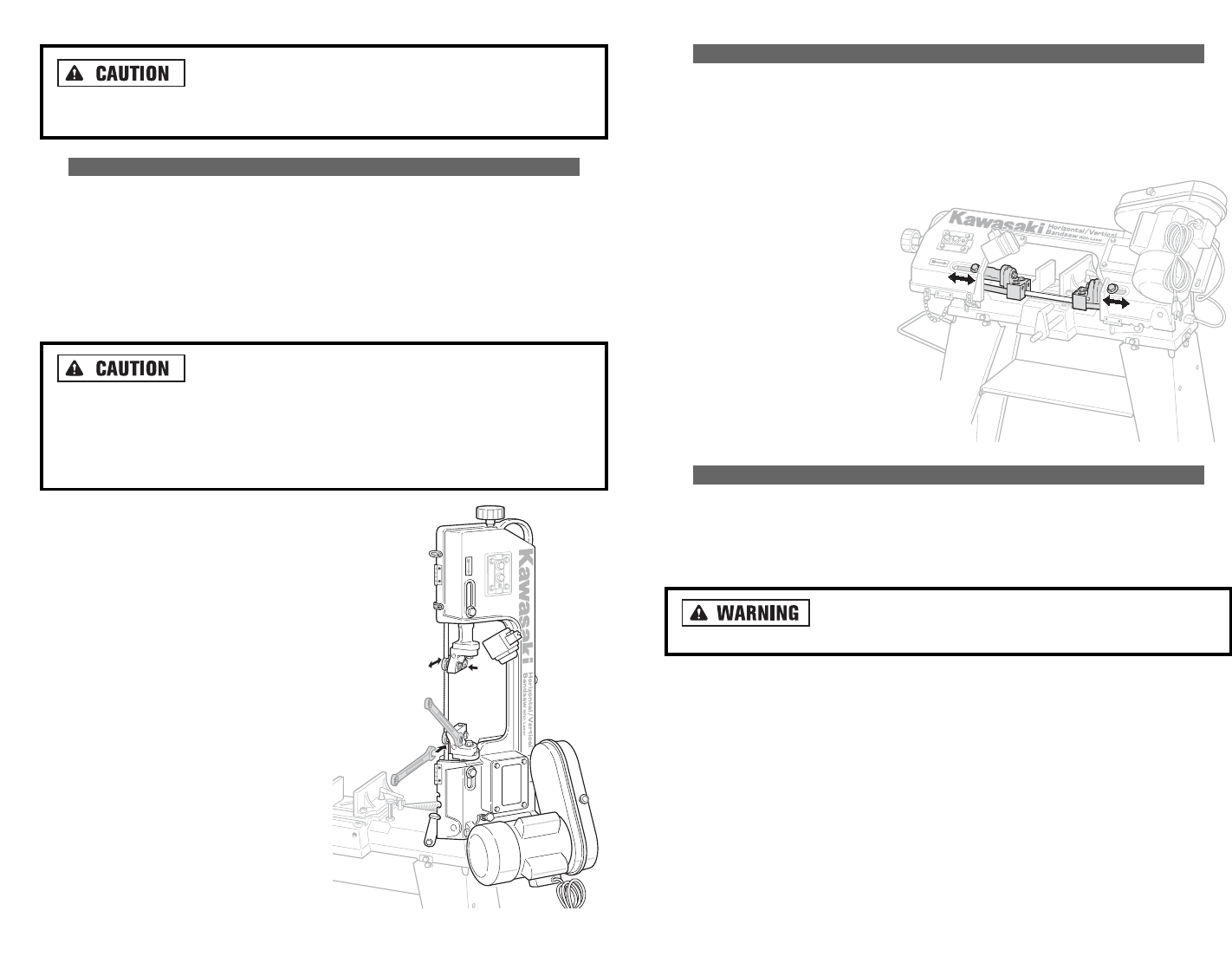

BLADE GUIDE ASSEMBLY ADJUSTMENT

The metal cutting band saw is equipped with two adjustable blade guide assemblies

permitting the adjustment of blade guide position for various widths of workpieces.

To ensure the most accurate cut and prolonging the life of the blade, the blade guide

assemblies should be adjusted to just clear the workpiece being cut.

1. Place the workpiece in the

vise and securely clamp in

place.

2. Adjust the catch blade guide

assembly by loosening the

hand knobs and positioning

the guides as needed.

3. Securely tighten the hand

knobs.

BLADE TENSION ADJUSTMENT

In order for the metal cutting band saw to cut effectively, the proper tension must

be put on the blade. If the tension is too loose, the blade may bind and possibly

break. If the blade tension is too tight, the blade could damage to the blade guide

bearings and possibly break.

DO NOT connect the band saw to the AC power source until

tool is completely assembled and adjusted per instructions in this manual.

FIGURE 6.

ADJUSTING THE BLADE

GUIDE BEARING

FIGURE 7.

ADJUSTING THE BLADE

GUIDE ASSEMBLY