ACCESSORIES - FILL CUP EXTENSION KIT(S)

1. The SGH humidifier is an electrode humidifier.

It produces steam at atmospheric pressure.

Pressure head must develop to push steam

through supply line and into air duct.

2. Combined resistance of duct positive static

pressure and steam line resistance creates a

small pressure head in steam cylinder. Total

amount of positive static pressure head is

reflected directly by water column differential

that develops between water in the fill cup

hose feeding cylinder and water level in

cylinder.

3. Standard dimensions of humidifier limit static

that can be tolerated before water will be

pushed high enough to spill over into overflow

tube in fill cup assembly.

4. To increase allowable water column (allowable

positive static pressure) an accessory Fill Cup

Extension Kit is available from Liebert. See

Figure #22.

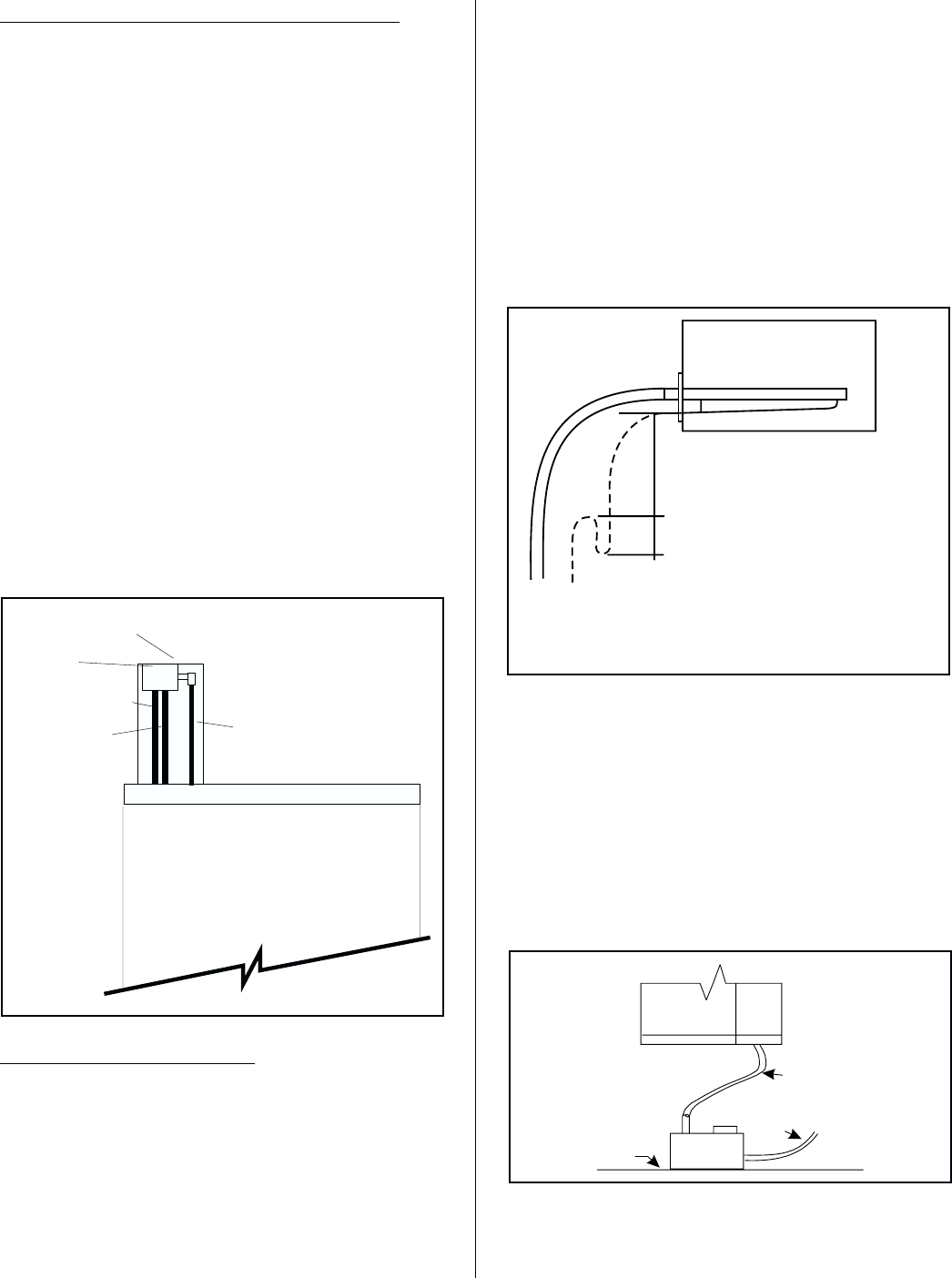

CONDENSATE RETURN LINE

1. Each steam distributor has a built-in

condensate return (3/8" O.D. copper tubing).

Flexible condensate return hose (3/8" I.D.)

available from Liebert, is recommended for

routing condensate back into humidifier’s fill

cup. Note: A short length of 3/8" O.D. copper

tubing is supplied by Liebert for use when

routing condensate hose back to humidifier’s

fill cup. Similarly, a short length of 3/8" I.D.

condensate hose with clamps is supplied with

Liebert’s steam distributors to serve as a

flexible coupling. DO NOT direct solder field

copper condensate line to steam distributors.

2. Always incorporate a trap in routing of

condensate return line. Condensate that

accumulates in trap will prevent possibility of

steam escaping. Depth of trap must exceed

duct static pressure by 2 inches of water

column. See Figure #23.

3. Condensate return line can not be run back to

fill cup if humidifier is within 36" of being level

with steam distributor. See Figure #18.

4. If steam distributor is mounted level with or

below humidifier, condensate line must be

routed to nearest floor drain or to a

condensate pump (available from Liebert).

See Figure #24.

5. Provide a “U” trap in condensate line even

when distributor is located in return air

plenum. It stops a suction action from

-8-

TRAP

3 FEET MINIMUM

CONDENSATE TRAP

DEPTH OF TRAP

MUST BE 2" MORE THAN

DUCT STATIC PRESSURE

OF WATER COLUMN

Figure #23

Trap to Prevent Steam in Condensate Line

HOSEFROMFILLVALVE

FILLCUP BRACKET

FILLCUP

OVERFLOWHOSE

FILLHOSE TO

CYLINDER

Figure #22

Fill Cup Extension Kit to Overcome Static Pressure

Humidifier

Drain Line

Drain

Pump

Floor

Surface

Line

Figure #24

Drain Pump (if necessary)