3. Liebert steam supply hose or field-supplied

piping should be sloped downwards from the

steam distributors to the humidifier. Slope

should be at least 2" in 12" to promote

condensate runback. See Figure #18. If this

slope is not possible, condensate must be

removed before the distributor. See Figure

#19.

4. Minimize the length of steam line and keep it

as straight as possible, minimizing bends.

Also, avoid using 90 elbows. Wherever

possible, use long radius turns (using tube

bender on oversized copper or pairs of 45

elbows). This will reduce the condensate

generated by heat loss. This will also reduce

the back pressure and avoid the need to

buy/install an accessory Fill Cup Extension Kit.

See Figure #22.

5. Ensure that the steam hose does not kink or

sag. The steam hose becomes more flexible

when hot. The hose should be supported to

prevent water traps. Only use steam hose for

connections or steam lined runs of 5 feet or

less. See Figure #20.

6. To ensure odor-free steam, always use Liebert

steam hose. Check steam hose and hose

couplings periodically for cracks, breaks,

kinks. Replace as required. DO NOT

substitute hose. Liebert is not responsible for

health effects or damage from substitute hose.

7. Steam lines for SGH 050 through 200 require

1-5/8" O.D. (nominal 1-1/2") copper pipe. For

steam runs longer than 40 ft use insulated

nominal 2" copper to ensure the draining of

condensate.

8. Do not use steel or plastic pipe for steam

distribution, or hose other than Liebert

supplied. Substitution will void warranty.

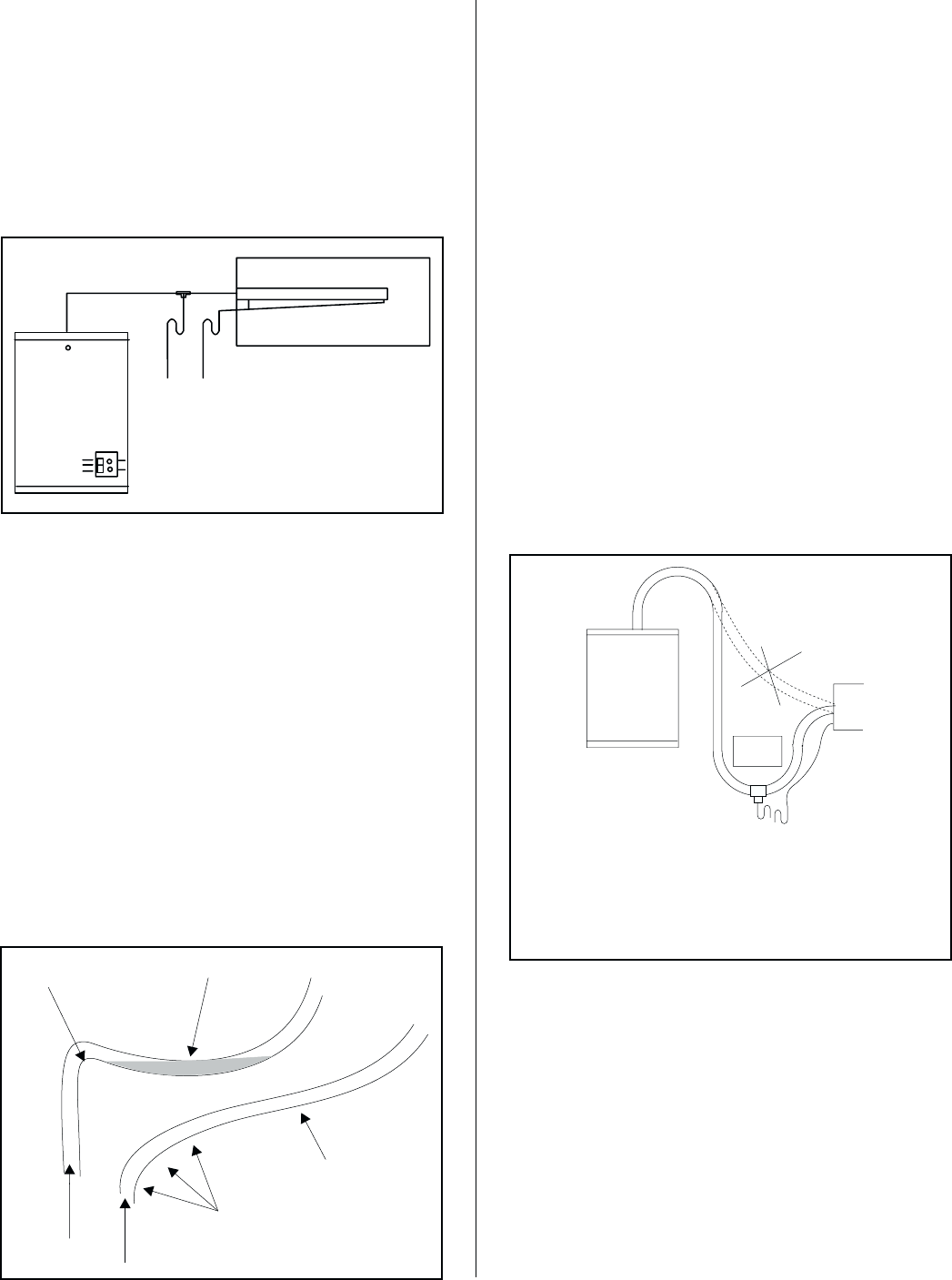

9. If steam line is routed below steam distributor

or if the steam distributor is lower than the

humidifier, a condensate trap ‘tee’ will be

required to remove water at this low point.

Run condensate from trap to nearest drain

lower than the distributor. See Figure #21.

10. All built-on blower packs are factory-fitted with

all steam hose connections. No further work

is required.

11. Do not run steam line more than 1 foot per

lb/hr output. Example, 10 lbs/hr should not

have a steam run longer than 10 feet. If long

runs are unavoidable, the humidifier should be

sized larger to compensate for condensate

losses and insulated copper should definitely

be used.

-7-

Condensate To Drain

Figure #19

Long Steam Lines

AVOID WATER TRAPS

AVOID KINKS

PROPER

SLOPE

GENTLE

SWEEPING

TURNS

Figure #20

Steam Hose Routing

NOT ACCEPTABLE

WITHOUT TRAP "TEE"

HUMIDIFIER

OBSTRUCTION

DUCT

CONDENSATE "TEE"

AT LOW POINT IN

STEAM HOSE

CONSULT FACTORY

TO FLOOR

DRAIN

CREATE A FALSE LOW POINT TO REMOVE

CONDENSATE WHENEVER THE

STEAM LINE MUST APPROACH THE

DISTRIBUTOR FROM ABOVE.

Figure #21

Condensate Tee at any Low Point in Steam Line