5. ALWAYS supply and install a shut off valve in

the water supply line dedicated to the

humidifier to facilitate servicing. Use ½"OD

copper to within 4 feet of the humidifier.

Reduce copper to 3/8" OD and connect to the

factory-supplied 3/8" olive compression fitting

under the humidifier.

DRAIN LINE

1. Humidifier is equipped with a 7/8" O.D.

unthreaded drain outlet on underside of drain

canal on bottom of the humidifier (see Figure

#15). A supplied reducer (see Figure #16)or

equivalent shall be installed on the drain line.

It will prevent backup in the drain pan and in

the cylinder due to partially blocked or badly

installed drain lines. This prevents rusting of

the drain pan and arcing due to

over-concentration. The drain canal has been

improved to prevent backup despite long or

gently sloped drain lines but it can not

compensate for flat or uphill runs.

2.

The drain line should not end in a sink used

frequently by personnel, or where plumbing

codes prohibit it. Route to a floor drain or

equivalent for safety reasons, since drain

water from humidifier can be very hot.

3. Keep drain lines as short as possible. Keep

drain lines sloped down, not level and not

up since low spots in drain lines will

accumulate sediment and cause backup.

The drain line should be 1" O.D. copper pipe

or larger. Do not use plastic pipe for drain

lines.

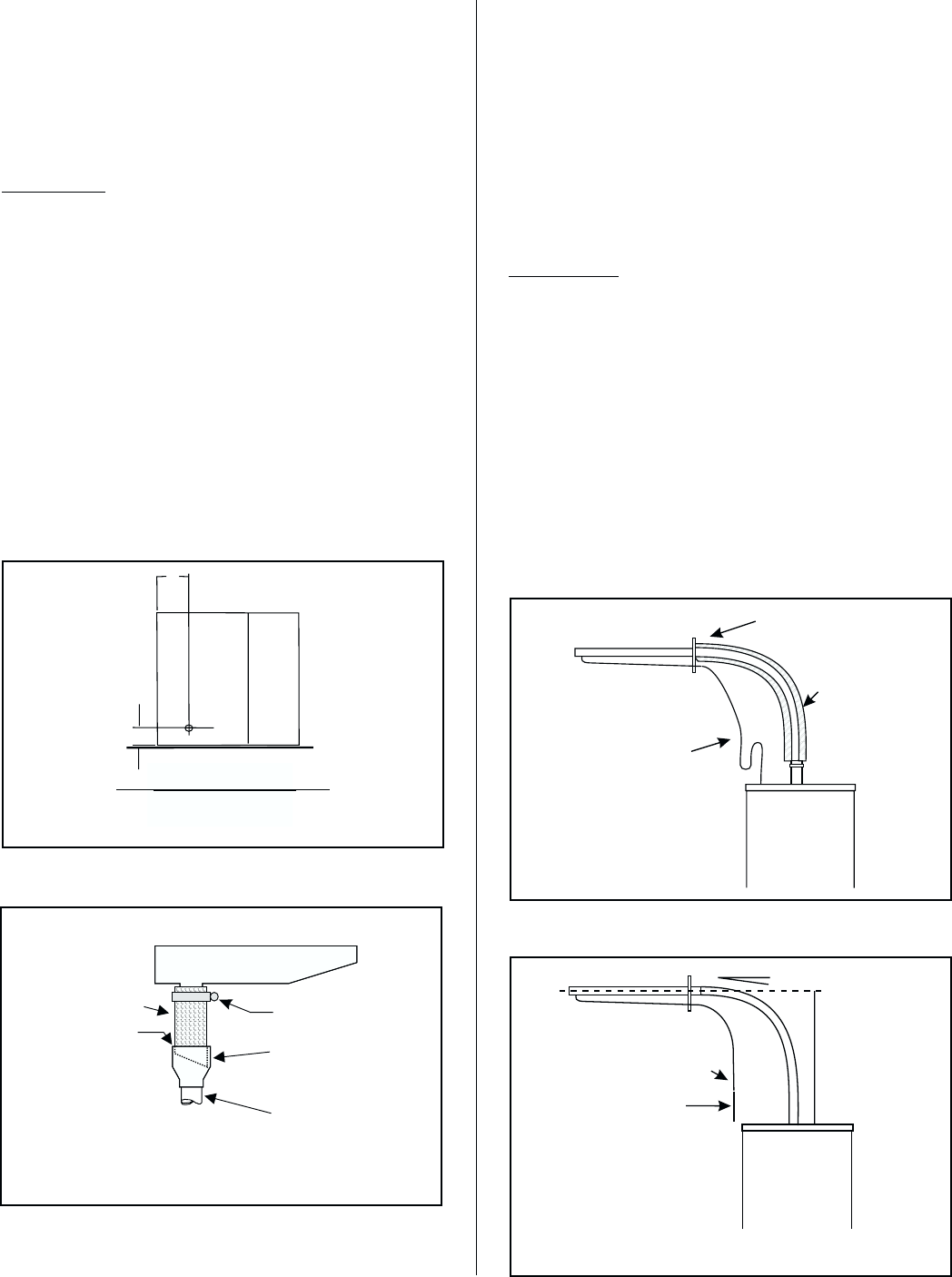

STEAM LINE

1.1. Steam lines for SGH models 010 through 020

require a minimum 7/8" O.D. (nominal 3/4")

copper pipe. For steam runs longer than 20 ft

use insulated nominal 1" copper to ensure the

draining of condensate.

2. Field-supplied hard copper with ½" thick

snap-on insulation is recommended for

steam supply, with Liebert supplied steam

hose coupling used to make connection to

cylinder. See Figure #17.

-6-

FactorySupplied

Taperedcutis

recommended

3/4”Copper Pipe

(NotSupplied)

Copper Reducer

(11/4”-3/4”)To

Serve AsFunnel

Drain.Factory

supplied.

Air Gap

NOTE: Steam hose should not reach bottom of the funnel.

In the event the building drain is plugged this becomes an

overflow

p

oint.

ClampAnd

7/8"I.D.Hose

Figure #16

MODEL A in. (mm) B in. (Mm)

010-020 1.0 (25) 5.0 (127)

050-100 2.2 (55) 6.2 (158)

200 LEFT 2.2 (55) 6.2 (158)

200 RIGHT 2.2

(

55

)

19.6

(

498

)

A

Wall

Bottom View

B

Figure #15

Drain Line Connection

Trap

See Section On

Condensate

Return Line

Field Supplied

Insulated Hard

Copper Pipe

Or Flexible

Steam Hose

Available

From Factory

Clamp To Steam Distributor

Or Remote Blower Pack

Figure #17

Steam Line Connection

Min. 12"

Min. 10 Degree Slope

Trap

* See Section On

Condensate

Return Line

NOTE: Trap must be 3' minimum down from steam distributor.

If not, condensate must be routed to drain.

Figure #18

Sloping the Steam Line