0

100

200

250

300

400

11000 27

8500 20

5700 14

3500 8

800 2

00

P

ERFORMANCE

Arc Performance

• 300 amps @100% duty cycle with output range up to 400 amps.

All ratings are at temperatures of 104°F/40°C.

• Arc Gouging – The Vantage

®

300 is capable of gouging with up

to a 1/4" carbon.

• CC-Stick mode is optimized for general purpose stick using

E7018 low hydrogen electrode.

• Built-in “hot” start for easier starts and restrikes minimizing the

electrode “sticking” to the work.

• Downhill pipe mode with active arc force control - enhanced

downhill pipe welding mode. Excellent for cellulosic electrodes.

Fast travel speeds, especially on fill passes. Arc control

adjustment for a soft, buttery arc or a more forceful digging arc.

• Standard DC Touch-Start TIG

®

welding, not scratch start, for

easy arc starting that avoids tungsten contamination and the use

of high-frequency.

• Excellent CV wire welding with cored-wire and MIG (CO

2

and

blended gas).

Generator Performance

• 3-Phase 240V AC generator power rated at 12.5 kW peak

(11 kW continuous) output to power industrial equipment such as a

plasma cutter, pump or inverter welder. Simultaneously weld and use

3-Phase AC power - for example, up to 5,300 watts can be delivered

while welding at 200 amps. Compare to competitive product which

does not have 3-Phase power.

• 3-Phase 240V receptacle on control panel eliminates the need to

hard-wire the connections.

• The Vantage

®

300 provides added value at the job site by

delivering up to 11.5 kW peak (10 kW continuous) watts of

1-Phase AC auxiliary power for equipment such as a Lincoln

plasma cutter. Also use for lights, grinders and other common

construction tools. And, you can simultaneously weld and have

access to AC power – 3,500 watts can be delivered while

welding at 250 amps. Compare to competitive product which

has no AC generator power at 225 amps welding and above.

• AC generator voltage is constant at 120V or 240V at any weld

dial setting.

• Two 120V GFCI duplex receptacles.

• All receptacles are circuit breaker protected.

Vantage

®

300

www.lincolnelectric.com

[2]

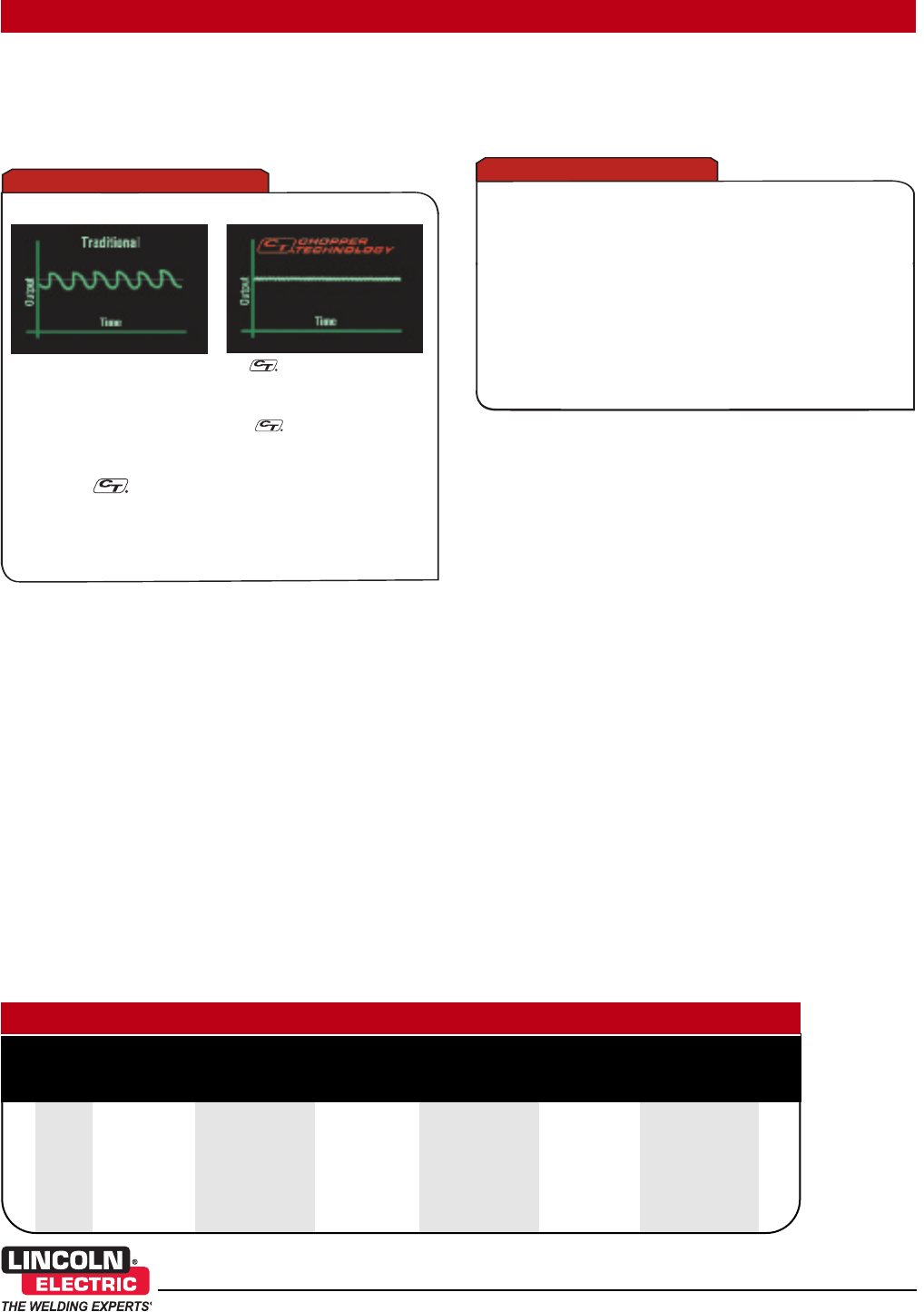

A CLOSER LOOK

Patented and award-winning Lincoln Chopper Technology

®

delivers superior DC arc welding performance for general purpose

stick, Downhill Pipe, DC TIG, MIG, cored-wire and arc gouging.

Benefits of Chopper Technology

®

include:

- Easy arc starting

- Smooth arc action

- Low spatter levels

- Excellent bead appearance

Traditional weld control is more

variable around the desired output.

Chopper Technology

®

d

elivers extremely fast response

f

or smoother output control.

WHAT IS CHOPPER TECHNOLOGY?

WHAT IS TOUCH-START TIG

®

?

Touch-Start TIG

®

uses a very low voltage to sense when

the tip of the tungsten electrode is touched to the

work piece. When this occurs, a complete circuit is estab-

lished. When the tungsten is then raised from the work piece,

the circuit senses a change in voltage and initiates the

appropriate welding current and voltage to support the TIG

welding process.

Enjoy the added benefits of Lincoln’s Touch-Start TIG

®

when

DC TIG welding. Not only do you avoid tungsten contamina-

tion when arc starting, but you also don’t need extra high

frequency equipment.

10000 42

8300 35

5300 22

3500 15

400 2

0 0

10000 -

8300 -

5300 -

3500 -

400 -

0-

Weld Amps

1 Phase

Watts Amps

SIMULTANEOUS WELDING AND AUXILIARY POWER

3 Phase

Watts Amps

Simultaneous 1 and 3 Phase

Watts Amps

AND

OR OR