B-8

OPERATION

B-8

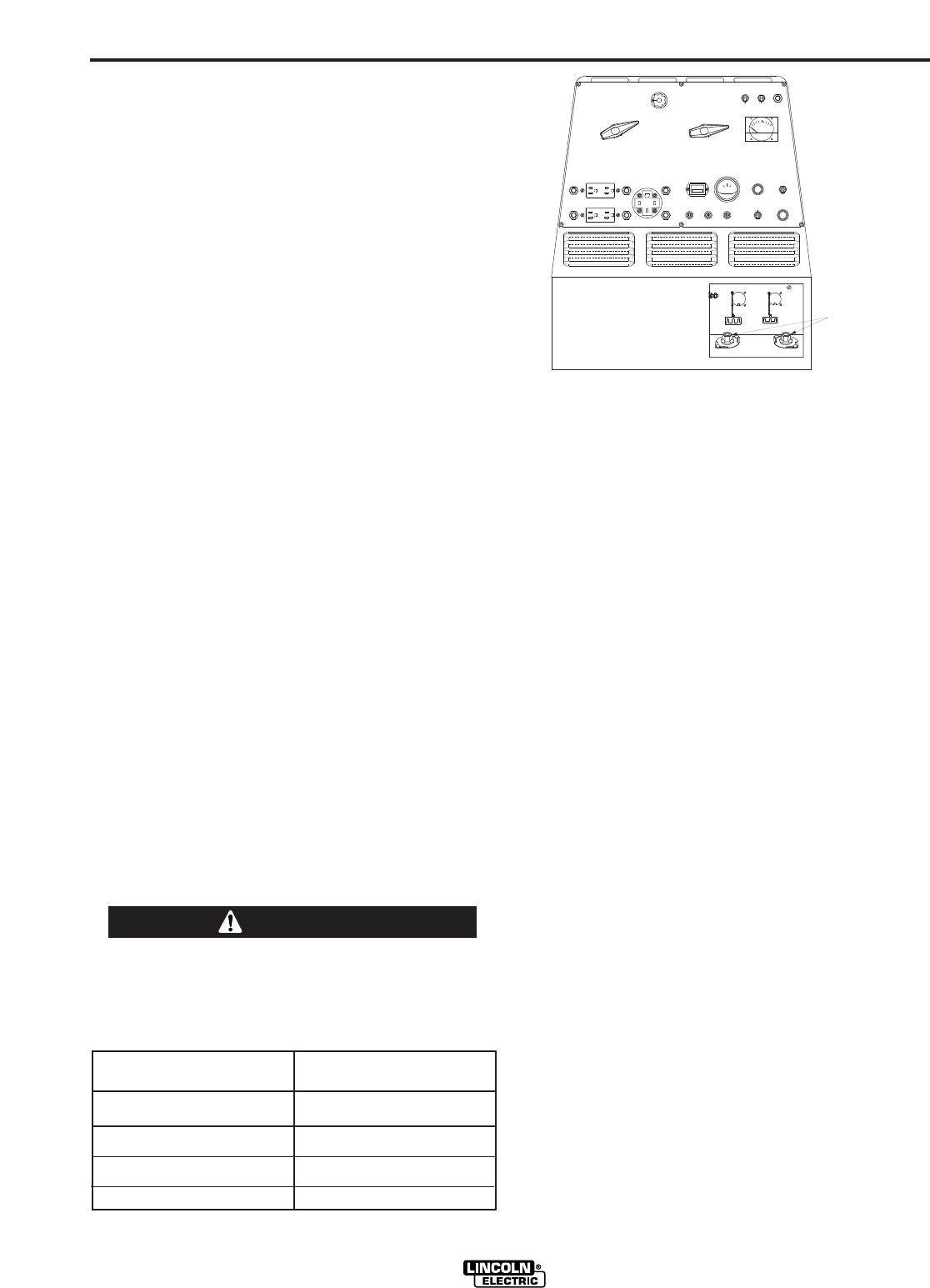

AC/DC STICK (CONSTANT CURRENT)

WELDING

1. Remove the flange nuts from output terminals and

place the work and electrode welding cables over

the terminals. See Figure B.4. Replace and tight-

en the flange nuts securely. Be sure the connec-

tions are tight.

2. Select the appropriate electrode. See “Welding

Tips 1" included with your RANGER 300.

3. Attach the work clamp securely to the work you are

welding.

4. Insert the electrode into the electrode holder.

5. Set the IDLER CONTROL to AUTO and start the

diesel engine.

6. Set the RANGE switch to a setting equal to or

slightly lower than the welding current recommend-

ed for the electrode being used. For the best weld-

ing performance, always set the RANGE switch to

the lowest CC-blue setting that will give the desired

weld current. This will assure that the OUTPUT

dial is set towards the high end of the dial. If the

OUTPUT dial is set at 10 and the welding current

is to low, move the RANGE switch to the next high-

est setting.

7. Set the POLARITY switch to the desired polarity

(CC-blue setting).

8. Set the OUTPUT control. For stick welding,

always use a setting between 5 and 10 on the dial

(blue range).

9. Strike an arc and begin welding. The OUTPUT

control can be adjusted while welding.

DO NOT change the RANGE switch setting while

welding. This can result in damage to the switch.

------------------------------------------------------------------------

FIGURE B.4

WELDING CIRCUIT CONNECTIONS

AFTER YOU FINISH WELDING:

1. Stop the engine.

2. Allow the electrode and work to cool completely.

3. Remove the work clamp from the work.

4. Remove any remaining piece of electrode from the

electrode holder.

5. If you are finished using the RANGER 300 for

welding, disconnect the welding cables from the

weld output terminals. Reattach the flange nuts

and leave them on the terminals.

RANGER 300 D AND 300 DLX

CAUTION

RANGE SETTING

ON MACHINE

ACTUAL

CURRENT RANGE

50

75

100

140

180

225

300

30 to 50 AMPS

50 to 75 AMPS

70 to 100 AMPS

95 to 140 AMPS

110 to 180 AMPS

130 to 225 AMPS

160 to 300 AMPS

FE

OUTPUT TERMINALS