A-2

INSTALLATION

WELD-PAK 3200HD

A-2

Read entire installation section before starting

installation.

SAFETY PRECAUTIONS

IDENTIFY AND LOCATE

COMPONENTS

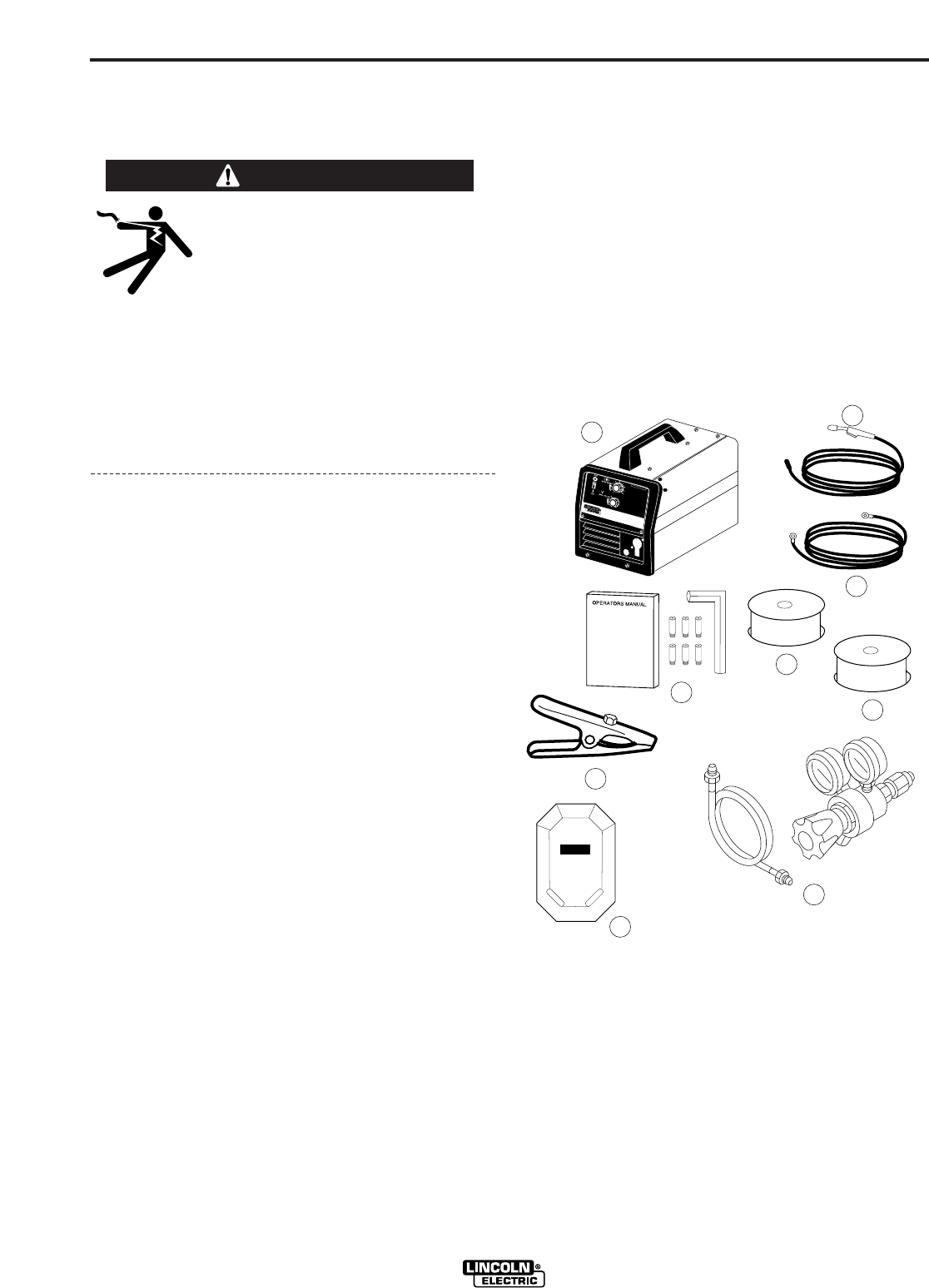

If you have not already done so, unpack the WELD-

PAK 3200HD from its carton and remove all packing

material around the WELD-PAK 3200HD. Remove the

following loose items from the carton (see Figure A.1):

1. WELD-PAK 3200HD

2. Gun and cable assembly

(1)

3. Literature and miscellaneous including:

a) This operating manual

b) 3 extra .023"-.025” (0.6 mm) contact tips

c) 3 extra .035” (.09mm)contact tips

d) Hex key wrench for removal of drive roll.

4. 10 ft (3.0 m) work cable.

5. Work clamp.

6. Sample spool of .025” (0.6 mm) L-56 MIG wire.

7. Sample spool of.035” (.09mm) NR-211 MP

Innershield Flux Cored Wire

8. Handshield with filter plate and lens.

9. Adjustable mixed-Gas Regulator & Hose.

10. Mig Nozzle Assembly

ELECTRIC SHOCK can kill.

• Only qualified personnel should perform

this installation.

• Only personnel that have read and under-

stood the WELD-PAK 3200 HD Operating

Manual should install and operate this

equipment.

• Machine must be plugged into a receptacle

which is grounded per any national, local

or other applicable electrical codes.

• The WELD-PAK 3200 HD power switch is

to be in the OFF (“O”) position when

installing work cable and gun and when

connecting power cord to input power.

WARNING

FIGURE A.1

1

2

3

4

7

8

9

6

5

11. Undercarriage:

a) Base

b) Gas bottle support base

c) (2) Gas bottle support brackets

For available options and accessories refer to the

Accessories Section of this manual.

1)

As shipped from the factory, the WELD-PAK

3200HD gun liner is ready to feed .023” (0.6 mm) -

.035 (0.9 mm) wire. The contact tip is sized for .023”-

.025” (0.6 mm) wire feeding.