E-2

TROUBLESHOOTING

E-2

MAGNUM™ PRO 350 and 550 FUME GUNS

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local

Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

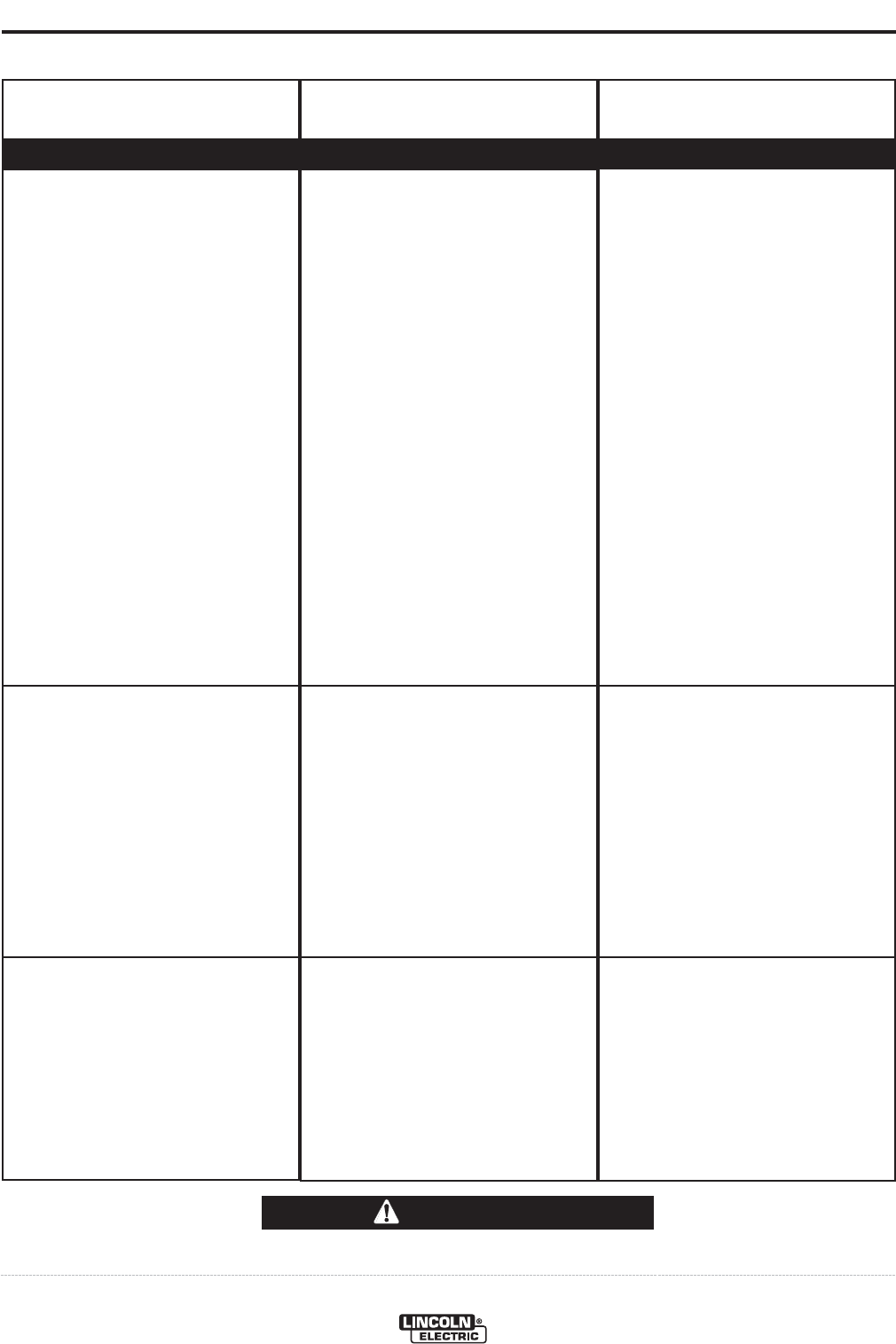

PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

No wire feed occurs when trigger is

pulled

Sluggish wire feed when trigger is pulled

1. Machine is switched off or unplugged.

2. Out of wire.

3. Contact tip burnback.

4. Fully or partially blocked gun liner

5. Bird nest.

6. Defective trigger (contacts open or

dirty).

7. Defective trigger circuit in gun.

8. No motor voltage or current from

machine.

9. Contact tip size too small for wire

diameter used.

1. Drive roll is worn or galled.

2. Machineʼs wire feed speed setting is

too low.

3. Wire is obstructed somewhere along

the wire feed path in the gun.

4. Low motor voltage.

1. Switch on or plug in machine.

2. Install full spool of specified wire.

3. Replace contact tip.

4. Remove and clean or replace gun

liner, (See Maintenance Section).

5. Cut out bird nest, reload wire, and

check for proper wire alignment.

6. Replace trigger (See Maintenance

Section)

7. Disconnect gun from machine and

check trigger circuit for continuity.

8. See Troubleshooting section in weld-

ing machineʼs or wire feederʼs instruc-

tion manual.

9. Replace contact tip with one that is the

correct size.

1. Clean drive roll or replace drive roll.

2. Increase wire feed speed.

3. Check for obstructions: remove any

wire shavings; remove kinked wire;

remove and clean or replace gun tube

liner (See Maintenance Section ).

4. See Troubleshooting section in weld-

ing machineʼs instruction manual.