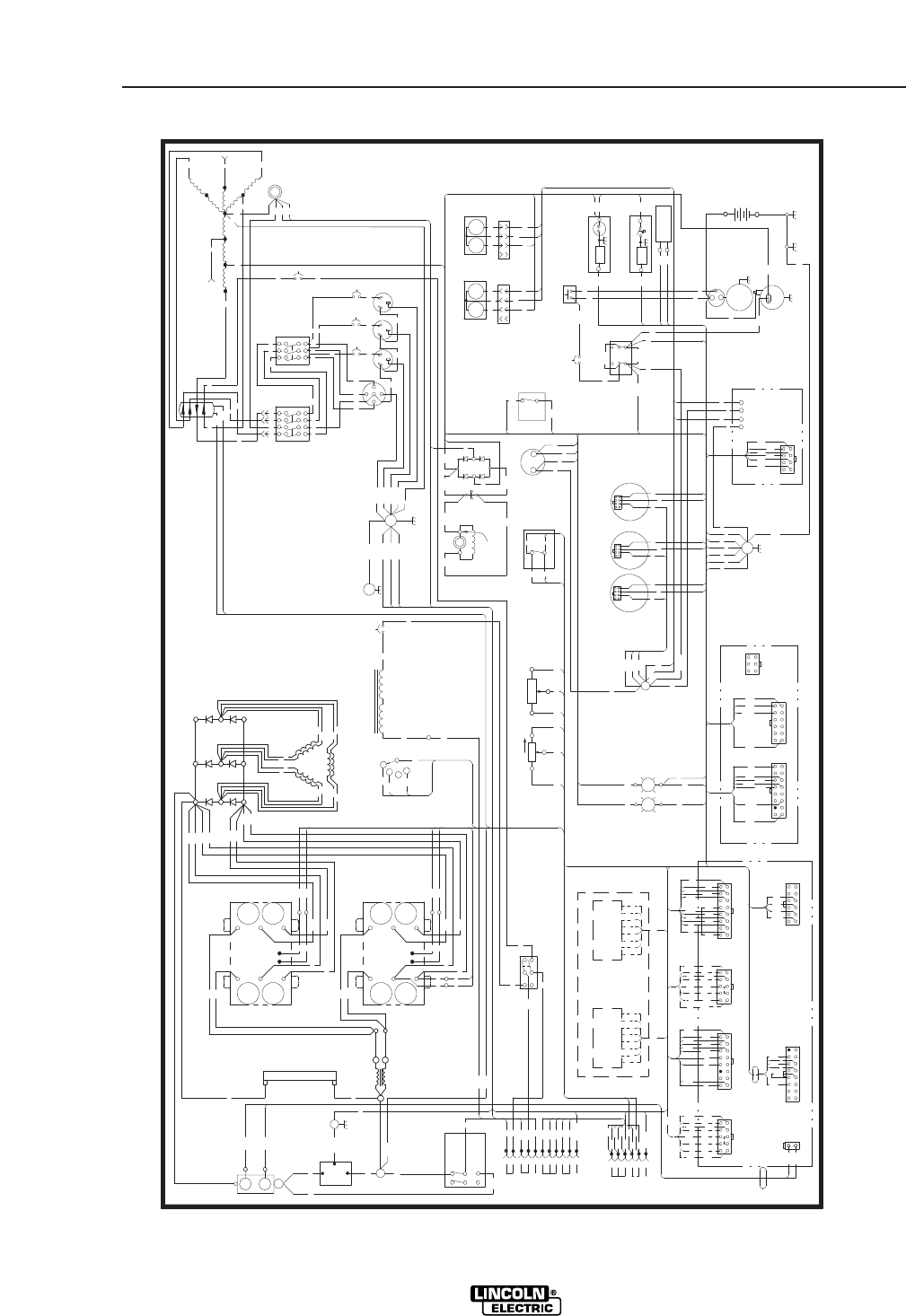

F-1 DIAGRAMS F-1

Vantage 575

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific dia- gram for your particular machine is pasted inside the machine on one of

the enclosure panels.

200

200B

5H

201

200A

201A

BRUSH

42B

41A

ROTOR

232L

232K

6

BRUSH

1

5

VOLT METER

15

AMMETER

PERIPHERAL BD.

WELD BOARD

270

403

405

208A

+

3 TURNS

THRU

TOROID

PCB3

PCB1

404

G4176

A.04

METERS OPTIONAL

I

AMPHENOL 2

201

CB4

CB3

CB2

5D

5F

5E

B

E

C

6

A

AUXILIARY GROUND STUD, BOTTOM

CENTER OF CONTROL BOX

GROUND STUD ON

CONTROL PANEL

STATOR LEADS "D"& "E" ARE TAPED AND TIED INTO HARNESS

AUXILIARY POWER LEADS A, B, & C TO PASS THROUGH

TOROID FOUR TIMES IN DIRECTION SHOWN.

LEAD "3" TO PASS THROUGH TOROID TWO TIMES IN DIRECTION SHOWN.

260

261

7

9

11

1

8

9

16

J7

J3

6

10

J4

J5

6

10

CONTROL, MODE SEL.

CHOPPER,POWER,PWM,THERMAL

271

200

R4

232B

232C

208C

INSULATED NEUTRAL

STUD ON BOTTOM

RIGHT OF CONTROL BOX

GND-J

3 TURNS

THRU

TOROID

12 VOLT GROUND

STUD ON LEFT SIDE

BACK OF CONTROL BOX

5N

5S

5L

5M

5T

5G

GND-A

GND-B

5H

GND-J

L1 CHOKE

5J

5K

5A

5B

5

5

3

5C

L1

L2

12

L3

GND-L

GND-C

GND-D

GND-E

VANTAGE 575 WIRING DIAGRAM (K2170-1 50HZ)

208B

GND-F

15A

15A

15A

N

A

E

N

A

E

N

A

E

E

N

L1

L2

L3

-+

+

-

3200MFC

300V

POSITIVE BRUSH CONNECTED

TO SLIP RING NEAREST

TO THE LAMINATION

PULL

COIL

HOLD

COIL

J54

P54

RED

WHT

BLK

1

2

3

4

232M

SHUTDOWN

SOLENOID

265

262

226

227

IDLER

SOLENOID

232L

4

3

21

BLK

WHT

RED

P54

J54

HOLD

COIL

PULL

COIL

SHOWN IN

"HIGH" POSITION

IDLER

CONTROL

262

262A

-

AUTO

HIGH

257

256

232R

+

HOUR METER

232E

2A

4A

4

2

279

10K

277

VIEWED FROM BACK

77

BACK

FROM

VIEWED

76

R1

278

PINCH POT

75

CCW

OUTPUT CONTROL

WELDING TERMINAL

CONTROL SWITCH

SHOWN IN "ALWAYS ON" POSITION

PIPE

TIG

CC

CV

41A

STATOR 42V WINDING

4

A

220

3

2

1

218

S5

214

MODE SELECTOR

SWITCH

222

41

42

10A

CB6

NEG

NEG

STATOR

WELD

WINDINGS

W1 & W6

W2 & W3

W4 & W5

W6

W6

W1

W1

W4

W5

W4

W5

W3

W3

W2

W2

RECTIFIER

BRIDGE

NEG

NEG

POS

POS

POS

POS

B8

B7

B7

B8

B3

B2

B1

B4

B5

B6

LEFT SIDE

CHOPPER

PCB6

POS

NEG

POS

NEG

W8

W7

25

23

B8

B7

14A

13A

B7

B8

14

13

B3

B2

B1

B4

B5

B6

RIGHT SIDE

CHOPPER

PCB5

NEG

NEG

POS

POS

25A

23A

W10

W9

-

50MV=400AMPS

+

204S

206S

206C

BYPASS

FILTER

ASSEMBLY

208B

208A

208

206A

206B

GROUND STUD

ON OUTPUT PANEL

GND-K

SWITCH SHOWN IN

POSITIVE POLARITY

POSITION

+

POLARITY

SWITCH

-

206A

21

115VAC

CONTACTOR

WORK

42VAC

GROUND

REMOTE

CONTROL

J

A

D

C

H

B

K

E

F

G

I

31

32

4B

77B

21

2B

75B

GND-A

41A

42A

76B

AMPHENOL 1

AMPHENOL 2

REMOTE

CONTROL

CONTACTOR

GROUND

A

B

C

D

E

F

2B

4B

GND-B

76B

75B

2A

4A

75A

76A

77A

77B

AMMETER

M1

M2

M3

M4

M5

M6

M9

M10

VOLTMETER

M1

M2

M3

M4

M5

M6

M9

M10

M1

M2

M3

M4

M5

M6

M9

M10

220

278

279

277

214

77

76

75

M1

M2

M3

M4

M5

M6

M9

M10

25

23

208B

256

260

1

9

16

8

25A

23A

13

14

257

261

6

12

J2

ENGINE,PERIPHERAL

232D

226

404

5G

1

16

9

8

2

4

75A

76A

77A

500

J1

AMPHENOL,I.D.

2

1

204S

206S

J6

SHUNT

ALT

405A

247

243

405B

405B

GOLD

SILVER

ENG

PROT

9

16

1

8

J31

403

5T

270

262A

405

232F

405A

1

6

7

J32

234

271

247

405B

12

PROGRAMMING

3

4

1

J30

6

232M

232N

232A

232R

12VDC

INSULATED

STUD

232C

OIL

PRESSURE

241

228

5L

229

232B

5M

COOLANT

TEMPERATURE

232K

5K

4

14

1

4

1

J53

J52

J51

FUEL

4

5

1

8

J43

PULL COIL BD

B1

B2

B3

B4

PCB8

5S

265

232N

227

RUN/STOP

SWITCH

SHOWN IN "RUN" POSITION

238B

236A

CB5

20A

232

232D

232F

236B

232A

232H

STOP

RUN

START BUTTON

238A

231

COOLANT TEMPERATURE

SENSOR & SWITCH

OIL PRESSURE

SENSOR & SWITCH

SWITCH

SWITCH

235

G

241

228

229

5J

234

235

WK

FUEL LVL.

SENSOR

SENSOR

SENSOR

5N

ENGINE

SUPPORT

LEFT SIDE

ENGINE BLOCK

+

-

STARTING

MOTOR

STARTER

SOLENOID

ALTERNATOR

L

P

IG

B

243

231

238A

12V BATTERY

232

238

2B

2B

2C

2C

2A

2A

L3

L2 L1

8

5C

5B

RCDI

30mA

A

B

C

1C 1B 1A

20A

CB1

10

1

7

222

218

31

32

CB7

10A

3

32A

32A

42A

42B

42V / 115V SWITCH

250

250

D

3

3