-21-

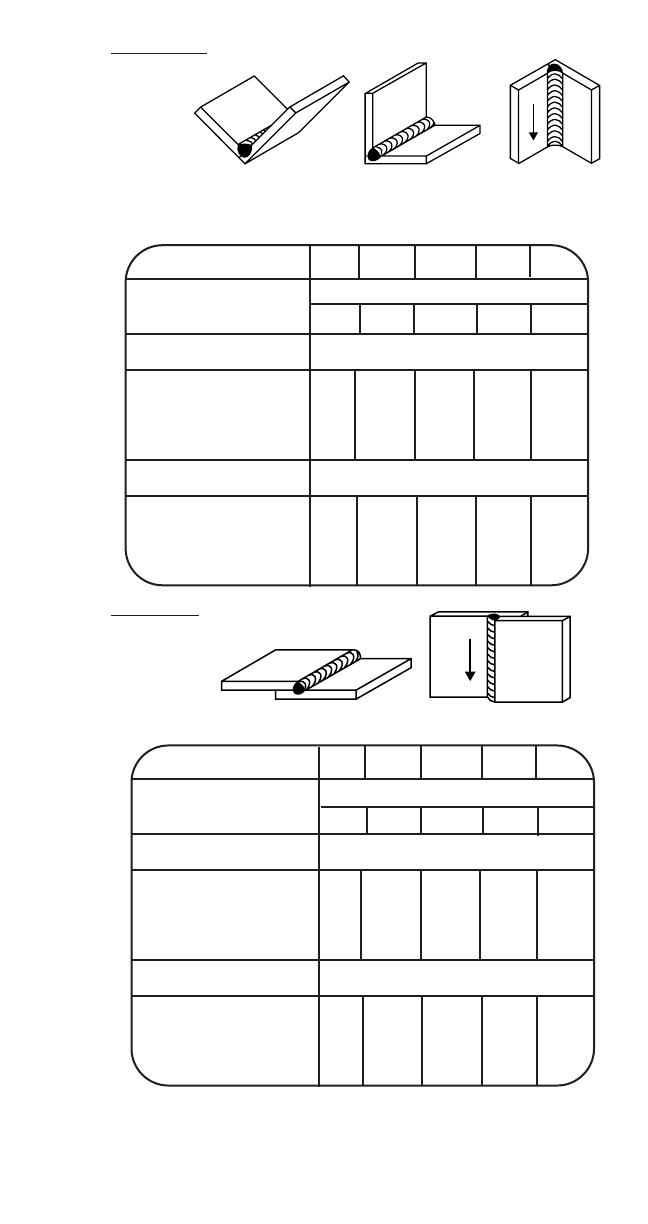

Fillet Welds

Also see High Deposition Procedures on page 28 for

14 to 10 gauge fillet welds with Jetweld electrodes.

Lap W

elds

Flat Horizontal Vertical (welded down)

Plate Size 18ga 16ga 14ga 12ga 10ga

Electrode/AWS Class Fleetweld 37/ E6013

Diameter (in.) 3/32 1/8 5/32 5/32 3/16

Position

(1)

0-30° Downhill

(5)

Current (Amps) 70 105 155 160 210

Polarity

(2)

AC AC AC AC AC

Arc Speed - In./Min.

(3) (4)

15 16 17 16 16

Lbs of Elec./Ft. of Weld .045 .053 .071 .079 .110

Position

(1)

30-90° Downhill

Current (Amps) 75 115 165 170 225

Polarity

(2)

AC AC AC AC AC

Arc Speed In./Min.

(3) (4)

16 19 21 20 18

Lbs. of Elec./Ft. of Weld .042 .049 .062 .070 .100

Flat Vertical (welded down)

Plate Size 18ga 16ga 14ga 12ga 10ga

Electrode/AWS Class Fleetweld 37/ E6013

Diameter (in.) 3/32 1/8 1/8 5/32 5/32

Position

(1)

0-30° Downhill

Current (Amps) 75 115 120 165 170

Polarity

(2)

AC AC AC AC AC

Arc Speed - In./Min.

(3) (4)

17 18 16 16 12

Lbs of Elec./Ft. of Weld .042 .055 .075 .085 .110

Position

(1)

30-90° Downhill

Current (Amps) 85 125 130 185 180

Polarity

(2)

AC AC AC AC AC

Arc Speed In./Min.

(3) (4)

21 22 21 21 14

Lbs. of Elec./Ft. of Weld .038 .050 .061 .069 .100

(4) Faster arc speeds can be obtained with Fleetweld 7 using DC- polarity and

these currents.