-9-

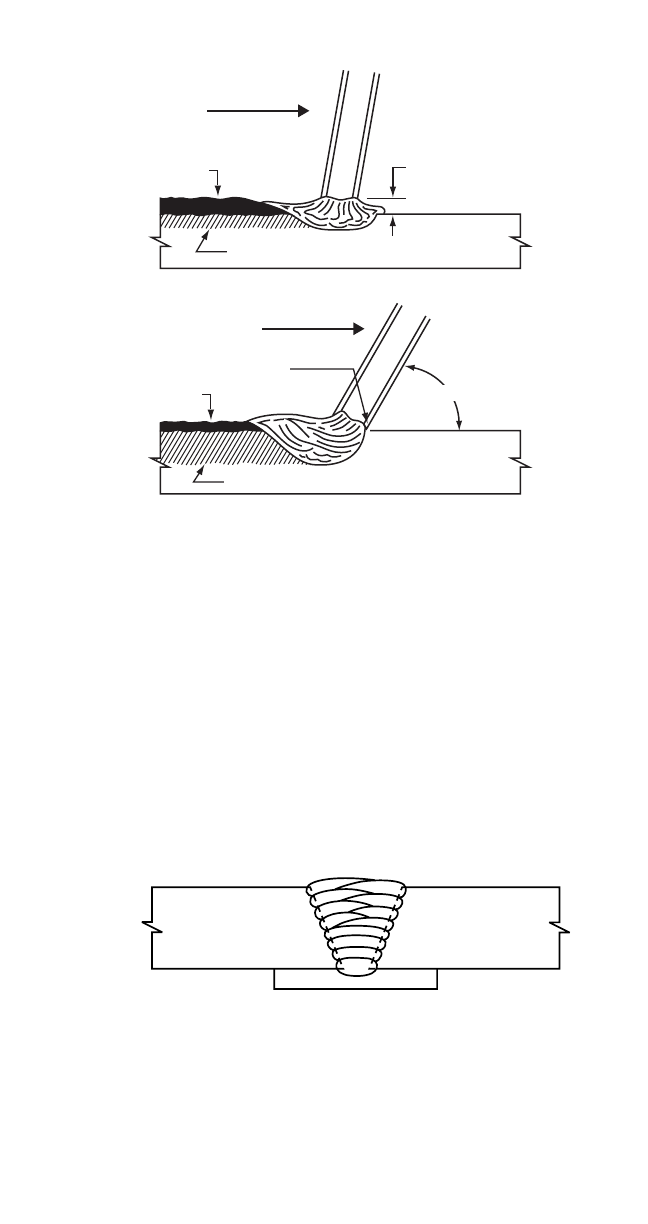

Travel fast, but not too fast for good slag coverage. Stay about

1/4” to 3/8” ahead of the molten slag. If travel speed is too slow,

a small ball of molten slag may form and roll ahead of the arc

causing erratic bead shape, spatter, and poor penetration.

Deep Groove Groove Welds – To hold the large pool of molten

weld metal from Jetweld electrodes, either a weld backing plate

or a root pass made with deep penetrating electrode (usually

E6010 or E6011) is required. Deposit Jetweld beads with a

stringer technique or a slight weave to obtain fusion to both

plates. Split weave welds are better than a wide weave near the

top of deep grooves. Size the second to last layer so the last

layer will not exceed a 1/16” buildup.

1/8" root gap between

electrode coating and plate

Slow travel

Fused metal

Plate

WRONG

Fast Travel

Fused metal

Electrode coating

touches plate lightly

Plate

RIGHT

60 to 80°

Slag

Slag