E-2

TROUBLESHOOTING

E-2

CV-300

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

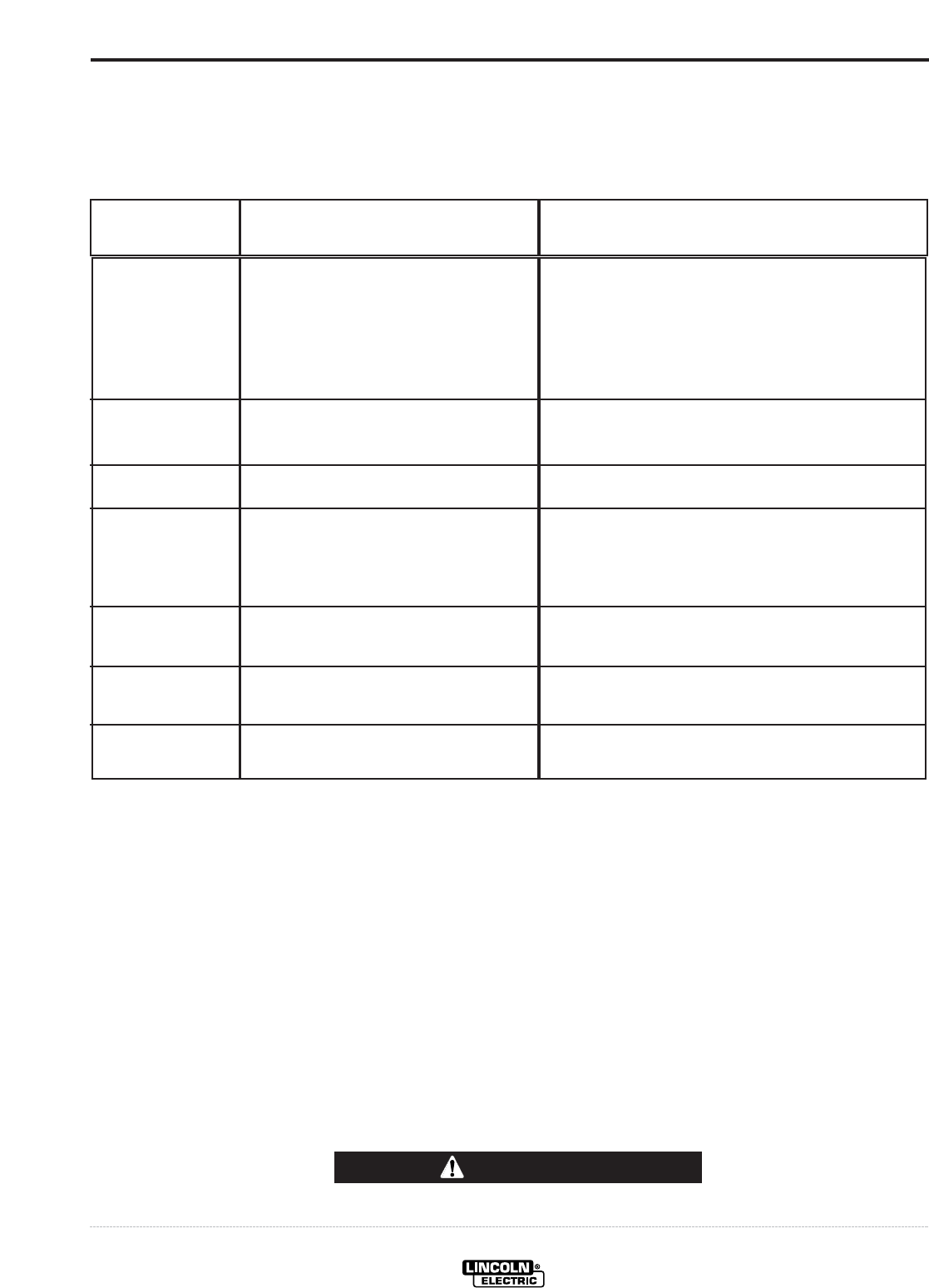

ERROR

CODE

TROUBLE REMEDY

E00

E10

E20

E30

E40

E50

E60

1. Output short circuited.

2. May be encountered while

starting or welding with 1/16" alu-

minum wire.

Thermostat circuit has opened.

Memory error.

1. Voltage Adjust potentiometer not

connected.

2. Remote Control not functioning

correctly.

Input line voltage too low.

Input line voltage too high.

Overload condition.

1. Turn power off. Remove short circuit.

2. a) Turn power off to clear error. Use recommended

wfs, voltage settings and angle of approach of wire

to work.

b) If problem still persists, call Local Lincoln

Authorized Field Service Facility.

Allow machine to cool. Be sure to provide adequate

ventilation for machine.

See PC Board Troubleshooting Procedure.

1. Check wiring between Voltage Adjust and the

Control PC Board.

2. See Options Troubleshooting Guide.

Turn power off. Insure machine input voltage is within

specifications. Turn power back on.

Turn power off. Insure machine input voltage is within

specifications. Turn power back on.

Reduce load on machine.

BUILT-IN DIAGNOSTIC ROUTINES AND ERROR CODES

The CV-300 Meter PC Board displays error codes when certain trouble conditions exist. The error codes, trouble

conditions, and possible remedies are listed below.

If, after attempting the remedies listed above, the error condition still exists, the problem may be with the wiring in

the following areas: the shunt (leads 218 and 219), or voltage feedback (leads 213B, 214B and 224B).