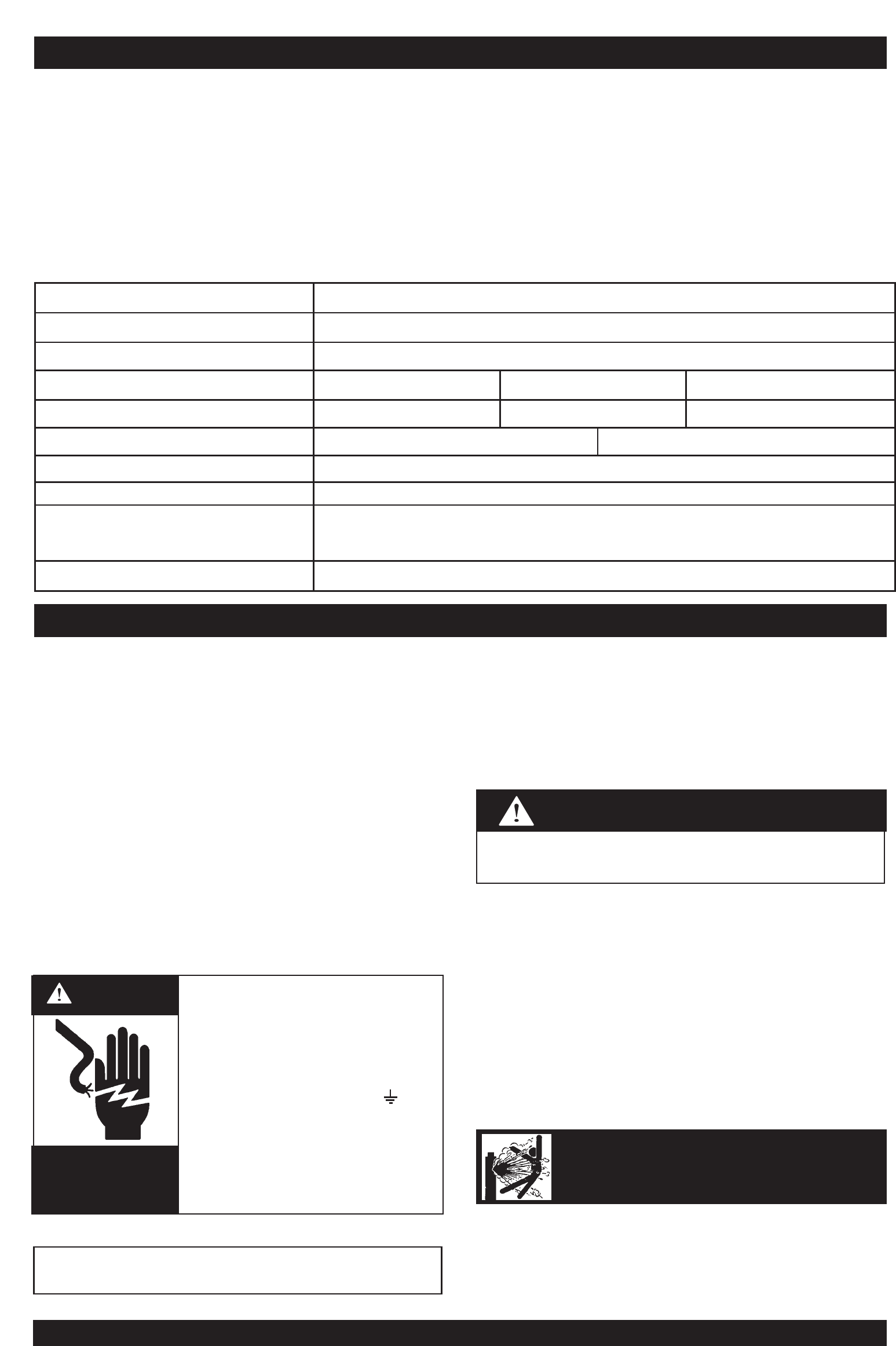

• Turn the input power off at the

disconnect switch before installing

or servicing this machine.

• Do not touch electrically “hot” parts

such as output terminals or internal

wiring.

• Connect grounding screw ( ) to a

good earth ground.

• Do not operate with covers removed.

• Turn power switch “off” before

connecting or disconnecting cables

or other equipment.

WARNING

HIGH

VOLTAGE

can kill

Page 6 CV320-I IMA 574B

PRODUCT DESCRIPTION

The CV320-I is a semi-automatic Constant Voltage DC arc welding power source and wire feeder. It combines a step controlled power

source with a separate solid state controlled wire feeder.

Excellent arc characteristics are provided for both gas shielded and self shielded welding within its current range.

For instructions on operation of the wire feeder refer to the separate instruction manual included. Standard features include output volt &

amp meters, a spot timer, gas purge facilities, a dual position 2 or 4 step trigger interlock, a Magnum FM400 gun, a regulator/flowmeter

and gas hose, a 10m electrode cable and wire feeder cable, a 3m ground cable assembly, a 3m long input lead and an undercarriage on

which a gas cylinder can be mounted.

Only qualified personnel should install or service this

equipment.

Location

Place the welder where clean cooling air can freely circulate in

through the intake louvers and out through the exhaust louvers.

Dirt, dust or any foreign material that can be drawn into the welder

should be kept at a minimum. Failure to observe these

precautions can result in excessive operating temperatures and

nuisance thermostat trips.

Wire Feeder Mounting

Locate the control cable at the rear of the CV320-I and plug into

the wire feeder. The control cable is already connected to the

CV320-I. Connect the supplied 1.5m electrode cable to the wire

feeder mechconnector and to the desired polarity terminal on the

front of the CV320-I.

Connection to Mains Supply

Before connecting the machine to the mains supply check that the

voltage and current capacity correspond to the machine voltage

and rated input current. Use a fuse or C/B per AS3000 or local

wiring rules.

The machine is supplied with an input lead fitted. Have a qualified

electrician fit a suitable input plug.

Once the above has been followed the machine can be plugged

into the mains outlet.

Shielding Gas Supply

(For the Gas Metal Arc Welding Process)

Refer “Safety in Welding and Cutting” - ANSI Standard Z49.1 and

WTIA Technical Note 7, available from the Welding Technology

Institute of Australia.

Obtain cylinder of appropriate type shielding gas for the process

being used.

1. Set gas cylinder on rear platform of the machine. Hook chain

in place to secure cylinder to rear of welder.

2. Remove the cylinder cap. Inspect the cylinder valve for

damaged threads, dirt and dust. For cylinders having an

external thread fitting, remove any dust and dirt from the

threads with a clean cloth.

CYLINDER may explode

if damaged

Part No. KA 1392 & KA1392-1

Maximum Open Circuit Voltage 45V

Output Current Range 20 to 400A

Duty Cycle 30% 60% 100%

Rated Output 320A/30V 240A/26V 190A/23.5V

Rated Input KA1392 415V 3ph 50Hz 13.5 amps KA1392-1 380V 3ph 50hz 14.7amps

Wire Speed Range 1-20 m/min

Weight (complete with u/c) 140 kg

H x W x L (mm) Over wire feeder,

cylinder tray & wheels

1220 x 580 x 842 mm

Operating Temperature -20˚C to 40˚C

Specifications

INSTALLATION

Never connect the green/yellow conductor to any of the

three active supply lines from the mains. This conductor is

to earth the machine as required by Electrical Regulations.

CAUTION