IMA 574B CV320-I Page 7

DO NOT ATTACH THE REGULATOR/FLOWMETER IF

CYLINDER VALVE IS DAMAGED! Inform your gas supplier of this

condition.

3. Stand to one side away from the outlet and open the cylinder

valve for an instant. This blows away any dust or dirt which

may have accumulated in the valve outlet.

4. Inspect the regulator/flowmeter for damaged threads and

seals, dirt and dust. Remove dust and dirt with a clean cloth.

DO NOT USE THE REGULATOR/FLOWMETER IF DAMAGE

IS PRESENT! Have an authorised repair station repair any

damage.

5. Attach the regulator/flowmeter to the cylinder valve and

tighten the union nut(s) securely with a spanner.

6. Attach the inlet gas hose to the outlet fitting of the

regulator/flowmeter, and tighten the union nut securely with a

spanner.

7. Before opening the cylinder valve, turn the regulator adjusting

knob counter-clockwise until the adjusting spring pressure is

released.

8. Open the cylinder valve slowly a fraction of a turn. When the

cylinder pressure gauge pointer stops moving, open the valve

fully.

9. The regulator/flowmeter is adjustable. Set it for the flow rate

recommended for the procedure and process being used

before starting to weld.

Gun and Cable

The Magnum FM400 gun and cable provided with the machine is

set up for 0.9/1.2mm operation.

1. Lay the cable out straight.

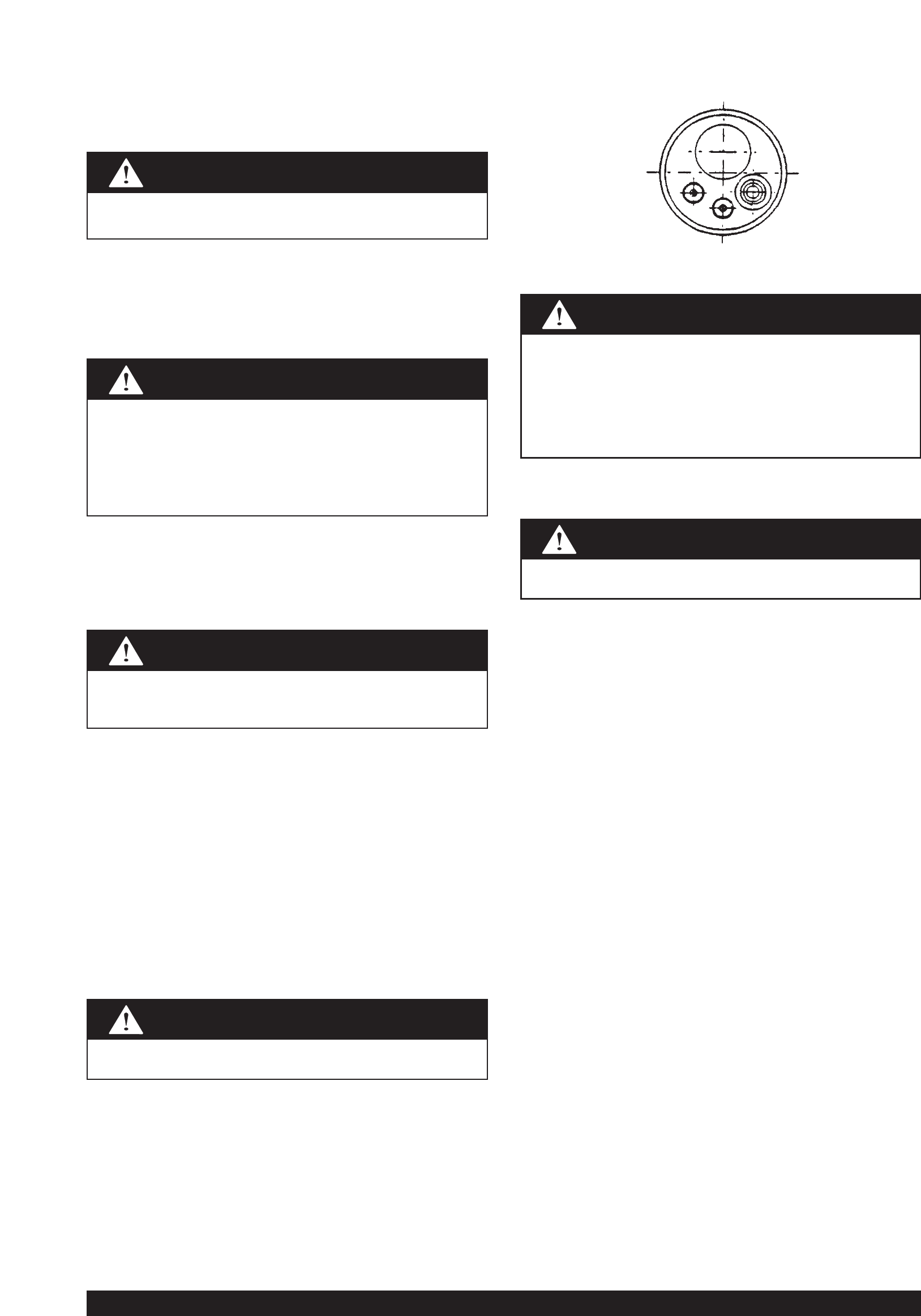

2. Make sure all pins on the gun cable connector are aligned

with the proper mating sockets on the front panel gun

connector and then join the connectors and tighten the hand

nut on the gun cable connector.

NOTE: If a gun and cable other than the Magnum FM400 gun are

to be used, they must conform to standard European-style

connector specifications. See diagram under.

The gun trigger switch must be capable of switching 10 milliamps

at 60 volts DC—resistive.

Output Polarity Connection

Connect the lead from the wire feeder to the output stud of the

desired polarity.

Connect the work lead to the other output stud.

Be sure to keep your face away from the valve outlet

when “cracking” the valve.

Gas under pressure is explosive. Always keep gas

cylinders in an upright position and always keep chained

to undercarriage or stationary support. Refer “Safety in

Welding and Cutting” - ANSI Standard Z49-1 and WTIA

Technical Note 7 available from the Welding Technology

Institute of Australia.

Turn the welder power switch off before installing gun

and cable.

The gun trigger switch connected to the gun trigger

control cable must be a normally open, momentary

switch. The terminals of the switch must be insulated

from the welding circuit. Improper operation of, or

damage to, the machine might result if this switch is

common to an electrical circuit other than the machine

trigger circuit.

Turn the welder power switch off before changing output

connection.

Never stand directly in front of or behind the

regulator/flowmeter when opening the cylinder valve.

Always stand to one side.

WARNING

WARNING

WARNING

WARNING

CAUTION

WARNING