!&+,$$,!'&

$&(*'

A

A

B

B

K

K

H

H

N

N

L

L

C

C

D

D

M

M

G

G

F

F

E

E

J

J

I

I

A

A

B

B

K

K

H

H

N

N

L

L

C

C

D

D

M

M

G

G

F

F

E

E

J

J

I

I

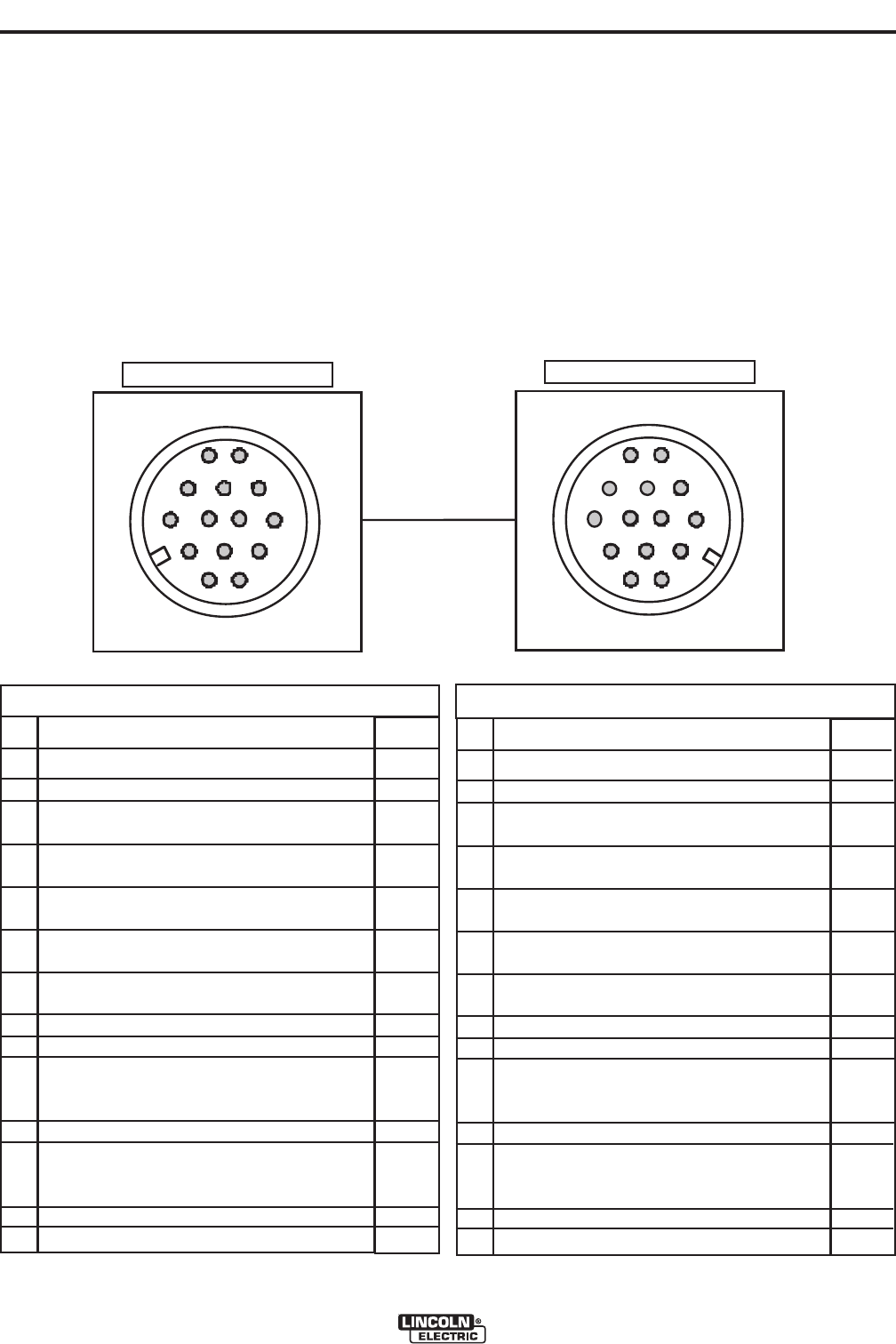

HA6G<BA

unused

Chassis GND

Welding Output Control

(trigger from feeder)

Welding Output Control

(trigger from feeder)

Remote Voltage Control

("+" supply, from power source)

Remote Voltage Control

(control signal from feeder or remote.)

Remote Voltage Control

("-" supply, from power source)

Work connection to feeder

42 VAC to feeder

Reserved

42 VAC to feeder

Reserved

unused

Electrode voltage from feeder

(<A

A

B

C

D

E

F

G

H

I

J

K

L

M

N

$847

--

GND

2

4

77

76

75

21

41

42

67

&$''&,*'$$#00

T

he control cable connecting the wire feeder to the

power source is specially made for the welding envi-

ronment.

The wire feeder power requires overcurrent protec-

tion. Connect the wire feeder only to power sources

where the overcurrent protection is no more than 15

amps.

Do not use more than 100 ft. (30.5 m) of control cable

between the wire feeder and power source.

HA6G<BA

Reserved

Reserved

Welding Output Control

(trigger to power source)

Welding Output Control

(trigger to power source)

Remote Voltage Control

("+" supply, from power source)

Remote Voltage Control

(control signal from feeder or remote.)

Remote Voltage Control

("-" supply, from power source)

Work connection from power source

42 VAC to feeder

Reserved

42 VAC to feeder

Reserved

unused

Electrode voltage to power source

(<A

A

B

C

D

E

F

G

H

I

J

K

L

M

N

$847

--

2

4

77

76

75

21

41

42

67

(BJ8E+BHE68

('/*+'-*

/!**

/<E88878E