!&+,$$,!'&

**$&T(*'0,*%

$'!&+(''$+'/!*

S#88C;4A7F;4<E6?BG;<A:4A7GBB?F

4J4L9EB@EBG4G<A:8DH<C@8AG

SBABGJ84E:?BI8FJ;8AG;E847<A:J<E8

BE6;4A:<A:J<E8FCBB?

S'A?LDH4?<9<87C8EFBAA8?F;BH?7<AFG4??HF8BE

F8EI<68G;<F8DH<C@8AG

------------------------------------------------------------------------

Loading 10 to 15 lb. (4.5 – 6.8kg) Spools.

A K468 spindle adapter is required for loading 2"

(51mm) wide spools on 2" (51mm) spindles. Use a

K468 spindle adapter for loading 2-1/2" (64mm) wide

spools.

/*&!&

GUN RECEIVER BUSHING

LOOSEN TIGHTEN

THUMB SCREW

OUTER WIRE GUIDE

SOCKET HEAD

CAP SCREW

CONNECTOR BLOCK

GUN RECEIVER BUSHING

LOOSEN TIGHTEN

THUMB SCREW

OUTER WIRE GUIDE

SOCKET HEAD

CAP SCREW

CONNECTOR BLOCK

(*'-*,'!&+,$$*!.*'$$+

&/!*-!+

S ,HEAG;8<ACHGCBJ8E'4GG;8

J8?7<A:CBJ8EFBHE68589BE8<AFG4?

?4G<BABE6;4A:<A:7E<I8EB??F4A7BE

:H<78F

SBABGGBH6;8?86GE<64??L?<I8C4EGF

S/;8A<A6;<A:J<G;G;8:HAGE<::8E8?86GEB78

4A77E<I8@86;4A<F@4E8;BGGBJBE>4A7

:EBHA74A76BH?7E8@4<A8A8E:<M87F8I8E4?F86

BA7F49G8EG;8:HAGE<::8E<FE8?84F87

SBABGBC8E4G8J<G;6BI8EFC4A8?FBE:H4E7F

E8@BI87BEBC8A

S'A?LDH4?<9<87C8EFBAA8?F;BH?7C8E9BE@@4<AG8

A4A68JBE>

------------------------------------------------------------------------

1. Turn power off at the welding power source.

2. Release the idle roll pressure arm.

3. Remove the outer wire guide by turning the knurled

thumbscrews counter-clockwise to unscrew them

from the feed plate.

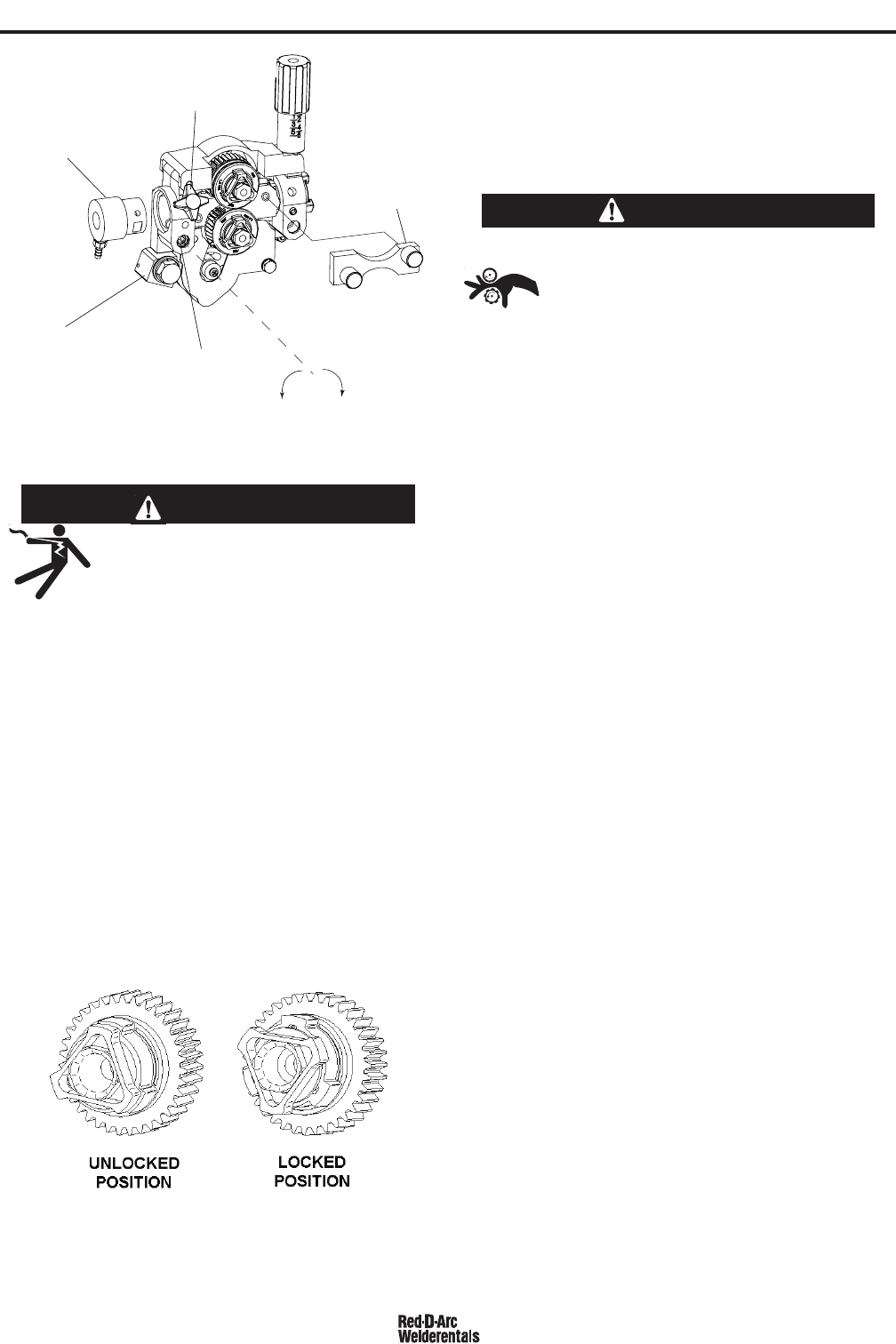

4. Rotate the triangular lock and remove the drive

rolls.

5. Remove the inner wire guide.

6. Insert the new inner wire guide, groove side out,

over the two locating pins in the feed plate.

/*&!&

!-*

7. Install a drive roll on each hub assembly secure

with the triangular lock.

8. Install the outer wire guide by aligning it with the

pins and tightening the knurled thumbscrews.

9. Close the idle arm and engage the idle roll pressure

arm. Adjust the pressure appropriately.

1. Squeeze the release bar on the retaining collar and

remove it from the spindle.

2. Place the spindle adapter on the spindle, aligning

the spindle brake pin with the hole in the adapter.

3. Place the spool on the spindle and align the

adapter brake tab with one of the holes in the back

side of the spool. An indicator mark on the end of

the spindle shows the orientation of the brake tab.

Be certain the wire feeds off of the spool in the

proper direction.

4. Re-install the retaining collar. Make sure that the

release bar snaps out and that the retaining collar

fully engages the groove on the spindle.