'(*,!'&

!!,$!+($1

(BJ8EHC

All of the LED’s will briefly illuminate during power-

up.

!7?8

The left display shows the preset wire feed speed.

The right display shows OCV. The wire feed speed

LED is lit. If the wire feeder is connected for elec-

trode negative welding, then the voltage display

shows a minus sign.

(See HFGB@8EFF<FG4A68(B?<6L in the front of this

Instruction Manual)

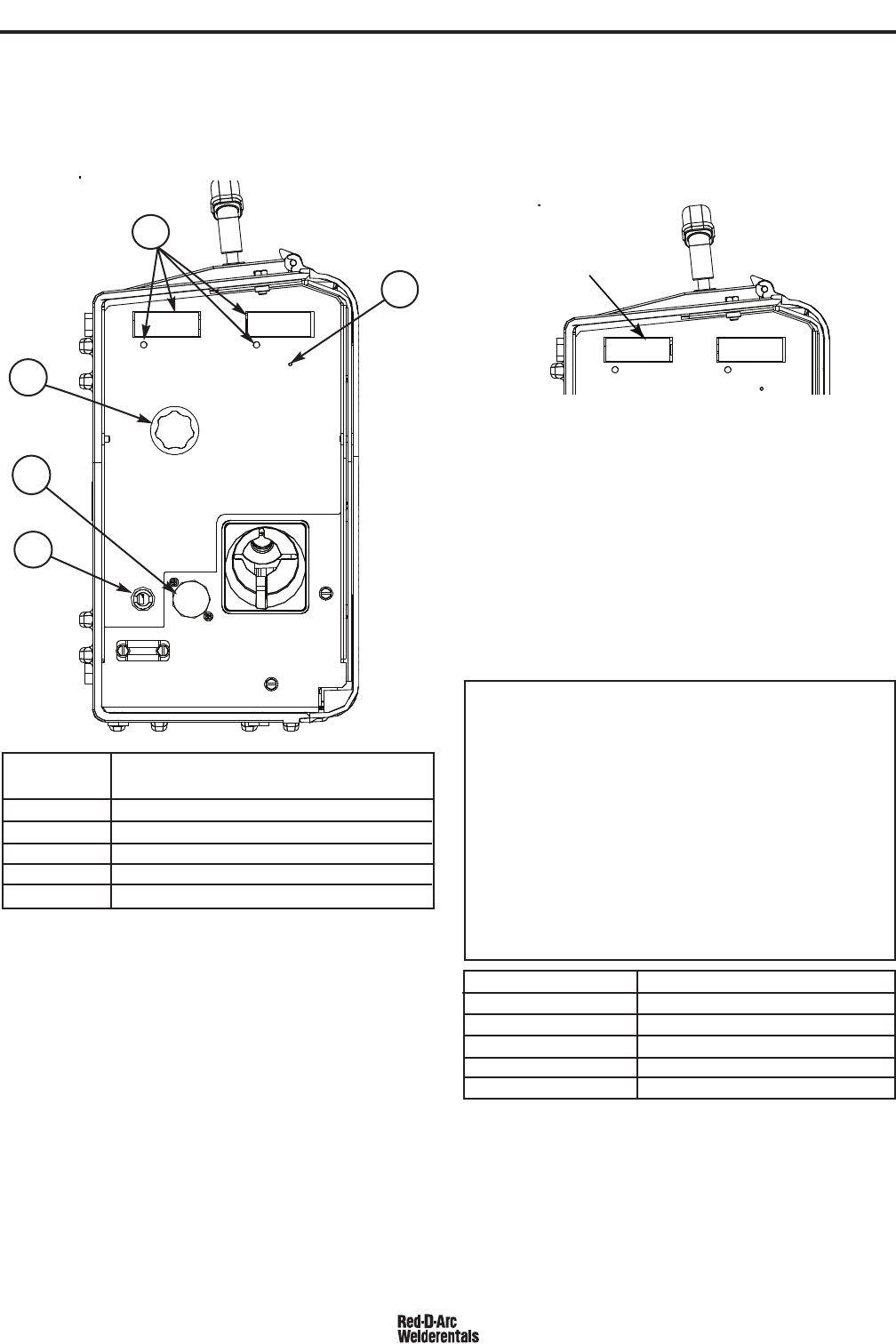

+*'&,'&,*'$+ +88<:HE8

!,%+*!(,!'&

1 Digital Display

2 Wire Feed Speed Knob

3 5-pin gun trigger connector

4 Work sense lead

5 Set-up Pushbutton

**$&T(*'0,*%

150

WFS

150

WFS

1

5

2

3

4

!-*

/8?7<A:

The value in the left display will show actual wire

feed speed. The right display shows the arc voltage.

If the wire feeder is connected for electrode negative

welding, then the voltage display shows a minus

sign.

/!*+(#&'

Use the Wire Feed Speed Knob to adjust the rate of

wire feed speed.

Because the wire feeder is powered by the arc volt-

age, the full range of wire feed speed may not be

available at low voltages. While welding, the display

will show actual wire feed speed. If the actual WFS is

less than set WFS, then the arc voltage may be too

low for procedure.

Arc Voltage

Max WFS (Inches Per Minute)

15V 400ipm

17V 450ipm

21V 570ipm

24V 650ipm

27V 700ipm

The serviceability of a product or structure utilizing the

RED-D-ARC LN-25™ PRO EXTREME wire feeder is

and must be the sole responsibility of the builder/user.

Many variables beyond the control of The Lincoln

Electric Company affect the results obtained in using

the RED-D-ARC LN-25™ PRO EXTREME wire feed-

er. These variables include, but are not limited to,

welding procedure, plate chemistry and temperature,

weldment design, fabrication methods and service

requirements. The available range of the RED-D-

ARC LN-25™ PRO EXTREME wire feeder may not

be suitable for all applications, and the builder/user is

and must be solely responsible for welding settings.