C-1

MAINTENANCE

C-1

SAFETY PRECAUTIONS

•Have a qualified technician do the maintenance

and troubleshooting work.

•Turn the equipment off and disconnect from main

power before working on the machine.

•Remove covers only when necessary and replace

them when the maintenance requiring their

removal is complete.

•Always use the greatest care when working near

moving parts.

------------------------------------------------------------------------

Read the Safety Precautions throughout this manual

and the welder instruction manual before working on

this machine.

Keep all equipment covers and devices in position and

in good repair. Keep hands, hair, clothing and tools

away from fans and all other moving parts when oper-

ating or repairing this equipment.

ROUTINE AND PERIODIC

MAINTENANCE

Replacing the Filter

To insure proper smoke removal, the filter (M12284-1)

typically requires replacement with a new or cleaned

element after welding with 75 to 150 pounds of

Innershield® electrode depending on the type of elec-

trode used and the efficiency of smoke pickup. (When

using the MIG welding process, the amount of elec-

trode between cleanings can be substantially higher.)

To replace the filter:

a)Turn the unit off.

b)Disconnect the power cord.

c)Remove the clamping ring from the top.

d)Lift the top and the filter from the canister.

e)Remove the wing nut on the bottom of the fil-

ter and install a new or cleaned element.

Make certain that the large flat washer is

placed under the wing nut.

f)Reassemble in reverse order.

NOTE: Used filters can be cleaned and reused.

NOTE: New filters will leak smoke for the first few min-

utes of operation.

Emptying the Spark Trap

The spark trap should be checked each time a filter is

changed. Clean accumulated material from bottom

spark trap every 300 to 400 pounds of electrode.

Cleaning of Cartridge Type Filters

• The dust and particulate matter collected by these fil-

ters can be dangerous to your health. Take neces-

sary precautions so you and your fellow workers do

not breathe the dust and particulate matter. Wear a

suitable respirator and, when cleaning filters, do it

under a force-ventilated hood such as a welding or

paint hood.

ª Properly dispose of collected material.

------------------------------------------------------------------------

Clean per the following instructions:

1.Gently brush the collected material off the outside of

the filter.

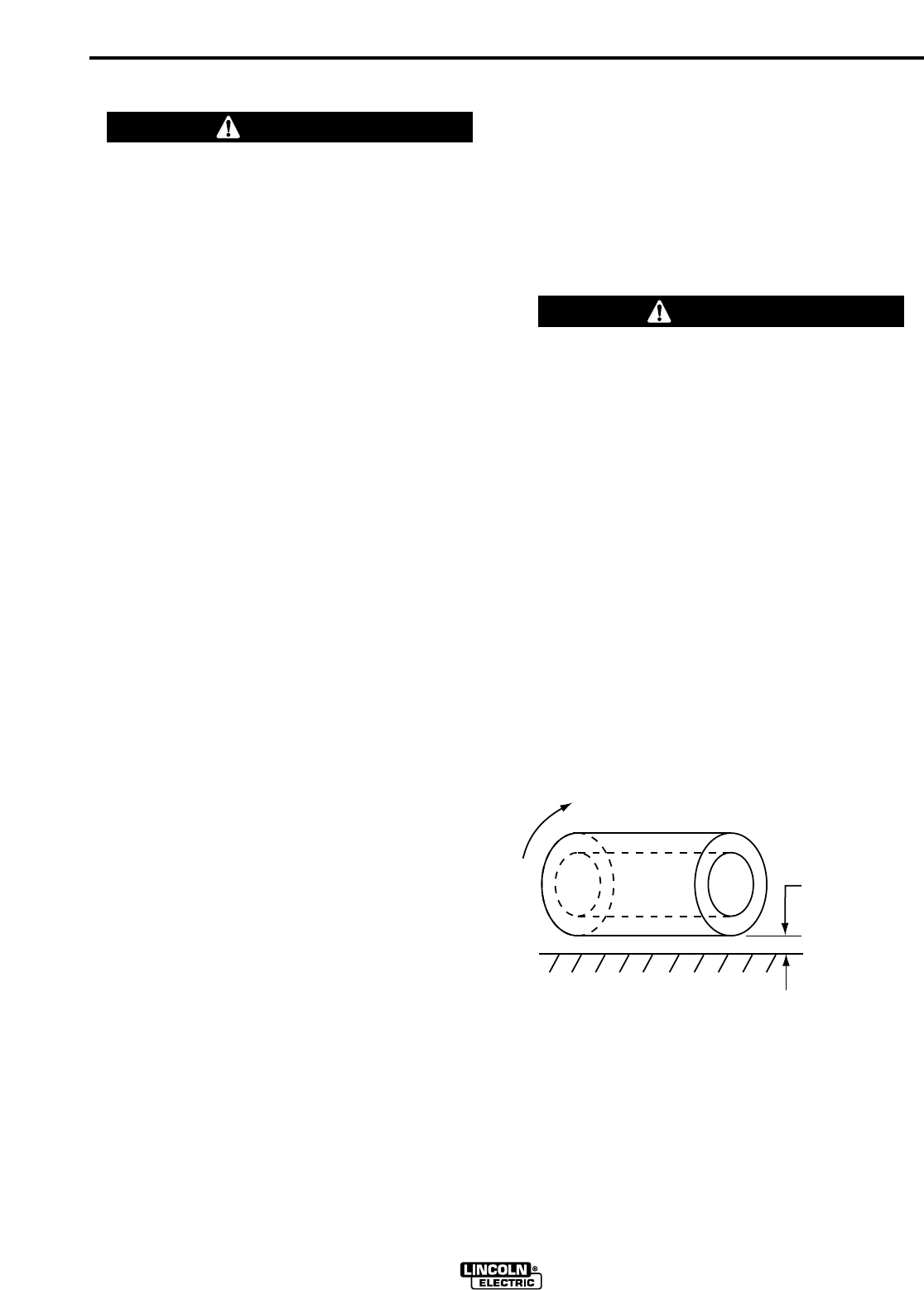

2.Loosen dust by successively dropping filter approxi-

mately one inch on a hard surface while rotating 10-

20° after each drop. Do not drop filter on its corner.

X-TRACTOR 1G

WARNING

WARNING

ROTATE AFTER

EACH DROP

FIGURE 2

APPROX. 1.00"

DROP DISTANCE

3.Enclose filter in a plastic bag several times larger

than the size of the filter. Secure the bag to the gas-

ket end of the filter. (A rubber band is effective.)

Blow air through filter using compressed air. Air sup-

ply must be 80-100 psi and the nozzle should be kept

at least one inch away from the filter element.