C-2

MAINTENANCE

C-2

*If air supply is limited to 30 psi, use a booster air gun

that increases dynamic pressure and still retains a 30

psi static pressure such as Guardair Booster Air Gun,

Model 57530XB made by Union Engineering

Corporation.

4.After Step 3, repeat the procedure in Step 2 for sev-

eral minutes to remove material loosened by the air.

5.All the material removed should be carefully put into

the plastic bag used in Step 3 for disposal.

With reasonable care in handling, these filters can eas-

ily be reused five or six times. The limiting factor in

their service life is the point where the element is frac-

tured or torn, permitting the continuous passage of

smoke. Using a fractured or torn filter may seriously

shorten the life of the vacuum unit.

Electrical Maintenance

Have a qualified electrician do the maintenance and

troubleshooting work. Turn OFF the arc welding power

source and disconnect control leads #31 and #4 at

power source or wire feeder. Remove the power cable

plug from its receptacle or turn the input power off

using the disconnect switch at the fuse box.

------------------------------------------------------------------------

Check motor brushes after 1,000 hours of operation or

about every six months. Brushes worn to 1/4 inch long

should be replaced. Brush part number is S14688-D.

Two brushes are required per motor. Instructions for

checking and/or replacement of the brushes are as fol-

lows:

a. Tools Needed: 4" flat blade screwdriver

3/8" open end or box wrench

1/4" socket or nut driver/

1/2" socket

5/16" socket or nut driver

4" socket extension and ratchet.

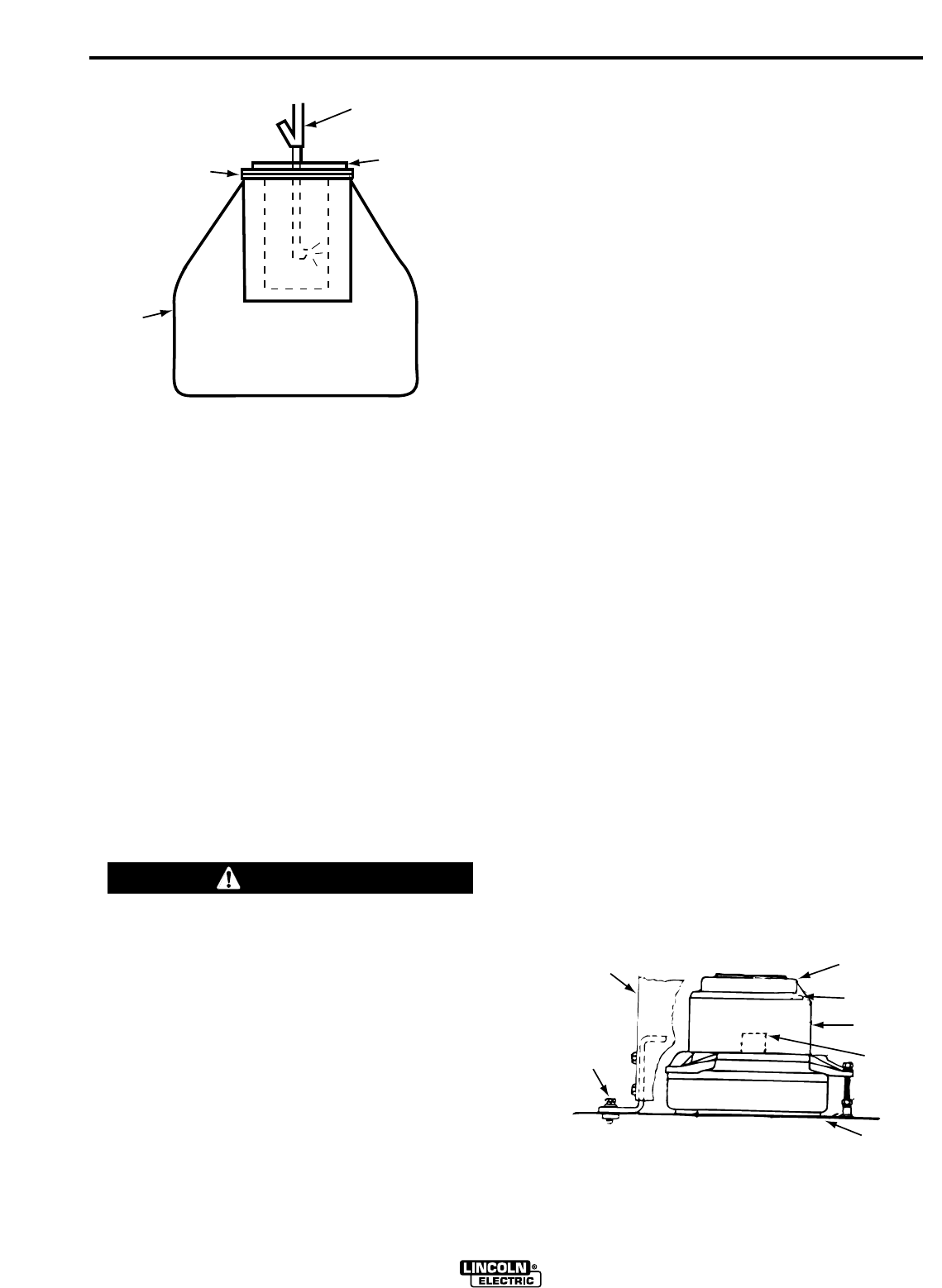

b. Removal of Housing Assembly - See Figure 4.

1.Turn off the input power being supplied to the

X-Tractor unit and the arc welding power

source being used.

2.Remove three 5/16"-18 x 5/8" bolts, lock-

washers and plain washer that hold control

housing to canister cover using a " socket

and 4" extension. Do not remove the acorn

nuts on the top cover.

3.Lift housing approximately 6" and tip to one

side.

4.Remove motor leads from terminal strip

using a 4" flat blade screwdriver.

5.Use a 3/8" wrench to remove the outer 10-24

nut from the grounding screw. Remove the

green motor lead from grounding screw.

6.Remove the housing from unit.

c. Replacement of Brushes

1.To insure optimum commutation on

reassembly, mark the relative location of the

screw heads in the slots and remove the two

#10-24 x 2 screws from the top end bracket

of the vacuum motor using a 5/16" socket or

nut driver.

X-TRACTOR 1G

WARNING

RUBBER BAND

PLASTIC

BAG

80 - 100 PSI

AIR SUPPLY

GASKET END

OF AIR FILTER

FIGURE 3

*

CONTROL

HOUSING

5/16-18x5/8" BOLT,

LOCKWASHER

& PLAIN WASHER

TOP END

BRACKET

#10-24 HEX

HEAD SCREW

MOTOR

COVER

BRUSH

HOLDER

CANISTER

COVER

FIGURE 4