A-2

INSTALLATION

X-TRACTOR 1G

A-2

Read this entire installation section before you

start installation.

SAFETY PRECAUTIONS

Do not attempt to use this equipment until you have

thoroughly read all installation, operating and mainte-

nance information supplied with your equipment. They

include important safety precautions and detailed

operating and maintenance instructions.

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

such as internal wiring.

• Turn the input power off at the fuse

box or by unplugging the power cable

before working on this equipment.

• Have a qualified person install and ser-

vice this equipment.

------------------------------------------------------------------------

MOVING PARTS can injure.

• Do not operate with covers open or fil-

ter removed.

• Keep away from moving parts.

------------------------------------------------------------------------

Only qualified personnel should install, use or service

this equipment.

GENERAL DESCRIPTION

The arc welding smoke exhaust unit will provide the

vacuum needed for one X-Tractor or Flux-Cored Fume

gun, collect visible particles that enter and discharge

the filtered air. This vacuum does not filter out gases.

The X-Tractor 1G is particularly valuable for light duty,

intermittent operation where frequent location changes

and low equipment costs are of prime importance. The

unit weighs 45 pounds and contains a reusable filter

element that collects the particulate matter. The filter

can be cleaned and reused.

A control circuit connected to the wire feeder slows the

motor to 1/2 speed when welding stops. With proper

maintenance, the average motor life is 2,000 hours.

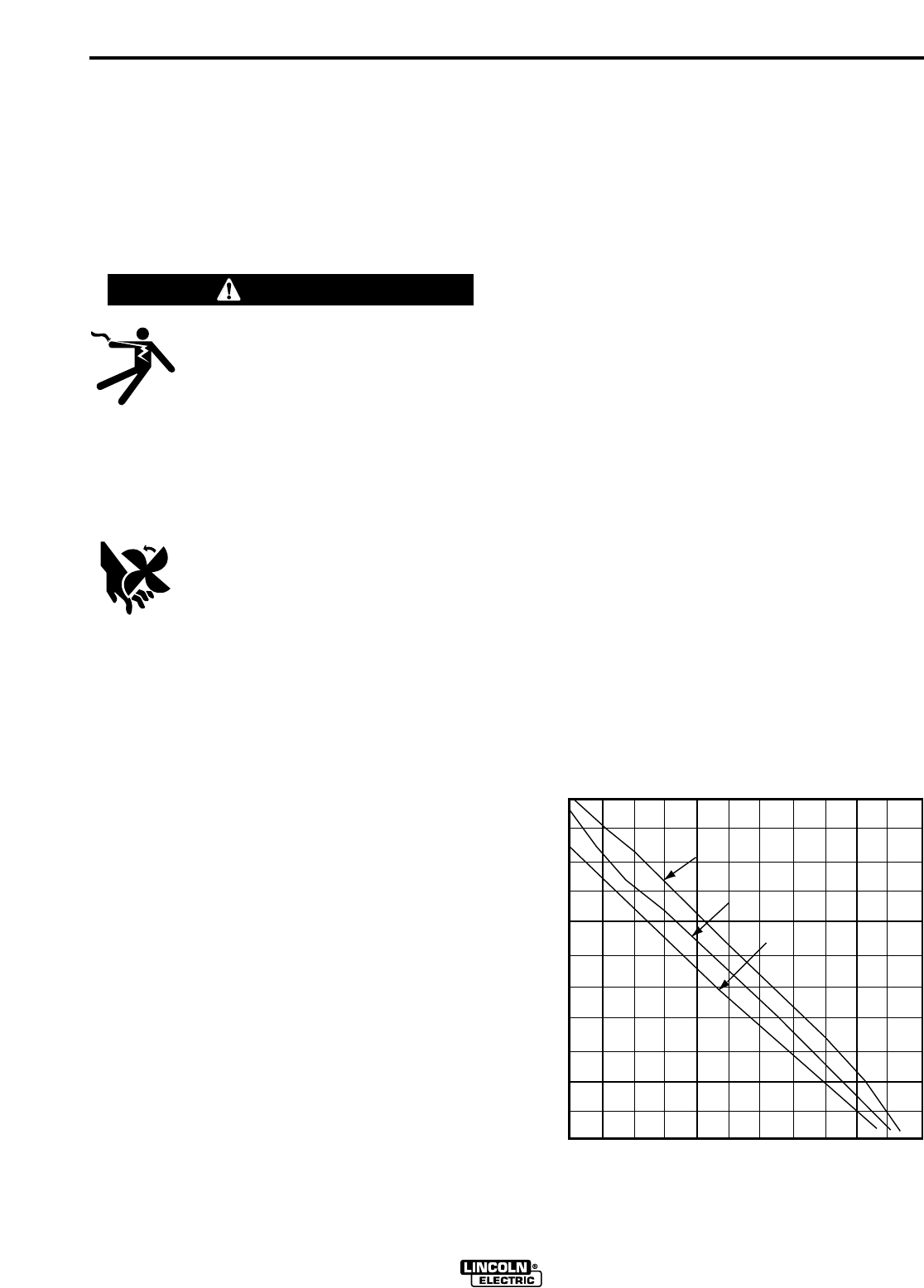

The smoke exhaust system consists of a vacuum

motor mounted on a canister with a filter mounted

inside the canister. See Figure 1 for nominal vacuum

motor output characteristics. The vacuum motor is

attached to the lid of the canister. A cover over the

motor provides both a drip-proof covering and a mount-

ing support for the switch and other electrical compo-

nents. A baffle is built into the cover to prevent re-cir-

culation of the motor cooling air. The switch turns the

unit on and lights a pilot light. A relay and resistors per-

mit the motor to run at half speed when not welding to

increase motor life. This allows enough air flow to cool

the gun when not welding and reduces the motor's

starting current. Operable from either 115 volts AC or

DC, the relay is energized when the operator pulls the

gun trigger.

The filter, made of a paper media, is attached to the

inside of the canister lid. Filters for these units are sim-

ilar to those used for large engine air cleaners. The

inlet pipe is fastened to the bottom of the canister and

is mounted tangentially to the inside diameter. A baffle

is mounted above the inlet pipe. When smoke and

sparks enter the canister, the sparks and heavier

smoke particles are retained in the bottom of the can-

ister by a centrifugal action. The centrifugal action and

baffle prevent sparks from damaging the filter media.

A muffler is standard to suppress the noise level of the

vacuum motor when operating at full speed. A hose

adapter is provided to allow easy connection of the

vacuum to any 1-3/4" (45 mm) exhaust hose. Lincoln

Electric has 1-3/4" hoses for both regular duty (PVC

flexhose S19947- ) and heavy duty (Reinforced rubber

S14927-8) applications.

WARNING

AIR FLOW IN CFM

0

0

10

10

20

20

30

30

40

40

50

50

60

60

70

70

80

80

90

90

100

100

VACUUM IN INCHES OF WATER

K179-4 AT 120 VOLTS

K179-5 AT 240 VOLTS

K179-5 AT 220 VOLTS

TYPICAL VACUUM MOTOR OUTPUT

CHARACTERISTICS

FIGURE 1