MACHINE SETUP FOR THE GMAW (MIG)

PROCESS

1. See “Recommended Processes and Equipment” for

selection of welding wire and shielding gas and for

range of metal thicknesses that can be welded.

2. See the “Welding ” chart on the inside of wire feed

section door or in this manual for information on

setting the controls.

3. Set the “Voltage” and “Wire Speed” controls to the

settings suggested for the welding wire and base

metal thickness being used. The voltage control is

marked “V” and the wire feed speed is marked olo.

4. Check that the polarity is correct for the welding

wire being used. Set the polarity for DC(+) when

welding with the GMAW (MIG) process. (See page

9 of the Installation Instructions on how to make

output polarity connections.)

5. Check that the gas nozzle and proper size liner and

contact tip are being used, and that the gas supply

is turned on. If adjustable, set for 15 to 20 cubic

feet per hour (7 to 10 liters/min) under normal con-

ditions; increase as high as 35 CFH (17 liters/min)

under drafty (slightly windy) conditions.

NOTE: The gas regulators included in the optional

K463 and K499 kits are preset and nonadjustable.

6. Connect work clamp to metal to be welded. Work

clamp must make good electrical contact to the

workpiece. The workpiece must also be grounded

as stated in “Arc Welding Safety Precautions.”

WELDING TECHNIQUES FOR THE GMAW

(MIG) PROCESS

The welding techniques for the GMAW (MIG) process

on light gauge material are basically the same as

welding with .035" (0.9 mm) NR-211-MP Innershield

electrode. (Review welding techniques in the self-

shielded FCAW Innershield section on page 14.) The

few exceptions are noted below.

The Correct Welding Position

When using the GMAW process on light gauge mater-

ial, weld from right to left (if right handed) pushing the

electrode ahead of the arc (see figure following). This

technique results in a colder weld and has less ten-

dency for burnthrough. You may weld in the opposite

direction as long as you are obtaining desirable

results.

The Correct Way to Strike an Arc

1. The arc is struck the same as for self-shielded

FCAW welding. However, for easier restrikes, the

ball at the tip end of the wire which forms after com-

pleting a weld may be removed with wire cutters.

2. When no more welding is to be done, don’t forget to

first close valve on gas cylinder (if used), momentarily

operate gun trigger to release gas pressure, then turn off

the machine.

The Correct Electrical Stickout

The electrical stickout (ESO) for GMAW (MIG) weld-

ing is 3/8 to 1/2 inch (10 to 12 mm). The same rules

apply as when welding with .035" (0.9 mm) NR-211-MP

Innershield wire.

The Correct Welding Speed

The same rules apply as those for self-shielded

FCAW welding. At first, it may be more difficult to

judge speed since no slag is forming behind the

molten pool. Watch the ridge where the molten puddle

solidifies.

Practice

To practice your GMAW (MIG) welding skills, use the

following:

Mild steel 16 gauge (about 1/16 inch)

Electrode Lincolnweld

®

.025 L-56 electrode

Shielding gas CO

2

Voltage setting “V” G

Wire feed speed olo 5

Then follow the instructions in the practice section on

self-shielded FCAW welding.

WELDING PROCEDURES

When GMAW (MIG) welding on sheet metal, remem-

ber to use the “forehand” push technique, and review

the welding procedures section on self-shielded

FCAW Innershield welding.

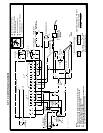

Welding in the Vertical Position

One variation of welding procedure is welding in the

vertical-up position. When welding in the vertical-up

position, use the proper gun angle shown below.

Gun angle for the GMAW process welding in the vertical-up position.

Push Technique

– 20 –