20

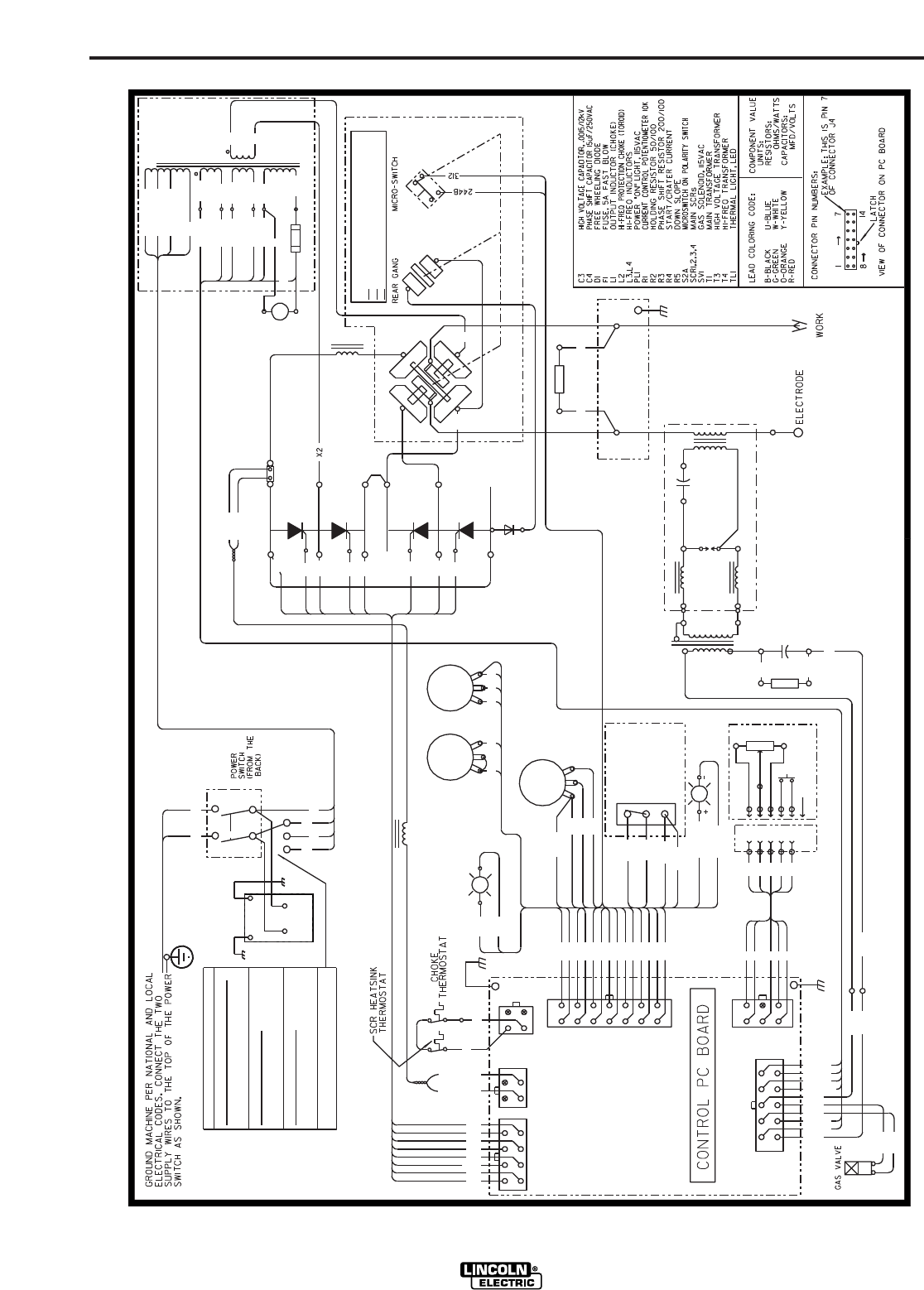

WIRING DIAGRAM

20

SQUARE WAVE TIG 175

NC

W 201

U 210

W 221 (+)

R 222 (-)

R2

R 209

H3 (380V)

L10808

217

T1

H1

DC+

FAN

244A

233

233

276

275

(REAR VIEW,

B

(-)

(+)

R5

MODE SWITCH

R1

2 STEP TIG

4 STEP TIG

240

POWER "ON" LIGHT

231

115VAC

B

POLARITY

SWITCH

(-)

D1

W 221

R 222

F

277A

244A

244B

A

NO

TOROID

CLOSED

OPEN

CLOSED

G

B X7

W X6

18VAC

W X5

B X4

18VAC

232

F1

B

B 230

W 204

H2 (240V)

232B

232A

220

E

STICK

BYPASS

PC BOARD

L1

BYPASS/

415 VOLT CONNECTION (AS SHOWN)

SCR4

CONNECT COPPER LINK FROM POWER

SWITCH STUD TO H4. TIGHTEN NUTS.

380 VOLT CONNECTION

CONNECT COPPER LINK FROM POWER

SWITCH STUD TO H3. TIGHTEN NUTS.

240 VOLT CONNECTION

CONNECT COPPER LINK FROM POWER

244

SWITCH STUD TO H2. TIGHTEN NUTS.

278

279

CURRENT

OUTPUT

235

234

AMPTROL

REMOTE

236

RECEPTACLE

238

REMOTE

SV1

E

C

S

ARC STARTER AS’BLY

L4

T3

115VAC

S3

243

VOLTAGE RECONNECTION

{

WIRING DIAGRAM - SQUARE WAVE TIG 175 (240/380/415/1/50/60)

G1

G2

X1

F

W X3

POS

STABILIZER

R4

217

G1

218

G2

G3

220

216

G4

277

B X8

D

FRONT GANG

SCR2

C

SCR3

BYPASS PC BOARD MUST ALWAYS BE

CONNECTED ACROSS POWER SWITCH.

L2

G4

218

J4

ELECTRICAL SYMBOLS PER E1537.

F

R 277A

216

H4

H3

H2

E

C3

SPARK

X1

278

276

J3

J2

J1

242

280

J4

A

10K A-B

J5

AT MINIMUM

209

210

230

238

234

235

L2

R

U

B

W

R3

S2A

TL1

SHOWN IN AC POSITION)

Y

H

B-D, A-E, C-F, G-H

B-D, C-E, A-F, G-H

A-C, D-E, B-F

H4 (415V)

POLARITY SWITCH MICRO SWITCH

DC-

AC

A

F

L1

A

D

C4

D

C

BB

236B

T4

E

J6

204

201

236

B 242

W

W

S2

B

243

CURRENT

244

280

B-RW

START/CRATER

237

231

275

277

SLOPE

DOWN

G3

H1

B

236A

C

TM

GAP

D

B 232B

236A

THERMAL LIGHT

240

281

279

312

281

78VAC

X2

S

F

115VAC

S

SCR1

PC BOARD

PL1

314

313

L3