B-2

OPERATION

B-2

TABLE B.1 – MIG WELDING MATERIAL/GAS COMBINATIONS

Material Gas

Carbon Steel CO2 or Argon/CO2

Low Alloy Steel CO2 or Argon/CO2

FLUX-CORED (INNERSHIELD) WELDING

The recommended electrode for the flux-cored, self-

shielded process is 0.035” (0.9 mm) diameter Lincoln

Innershield NR-211-MP on 1 lbs. (.5 kg) spools.

SEQUENCE OF OPERATIONS

WIRE LOADING AND THREADING

Refer to Figure B.2.

Turn machine power switch to the OFF (“0”) position

before working inside the wire feed enclosure.

Make sure that the wire feed drive roll and the contact

tip of the gun match the diameter and type of wire

used.

1. Push the spool onto the spindle so that the wire

feeds off the bottom of the spool, toward the drive

roll.

2. Push the spool spacer onto the spindle, against the

spool.

3. Slide the spring onto the spool, then press on the

spool lock, turning it clockwise to lock the spool

assembly onto the spindle.

WELDING CAPABILITY

The machine is rated at 70 amps, 17 volts, at 20%

duty cycle on a ten minute basis. It is capable of high-

er output currents at lower duty cycles.

LIMITATIONS

The machine is recommended for welding on mild

steel up to 1/8” thick.

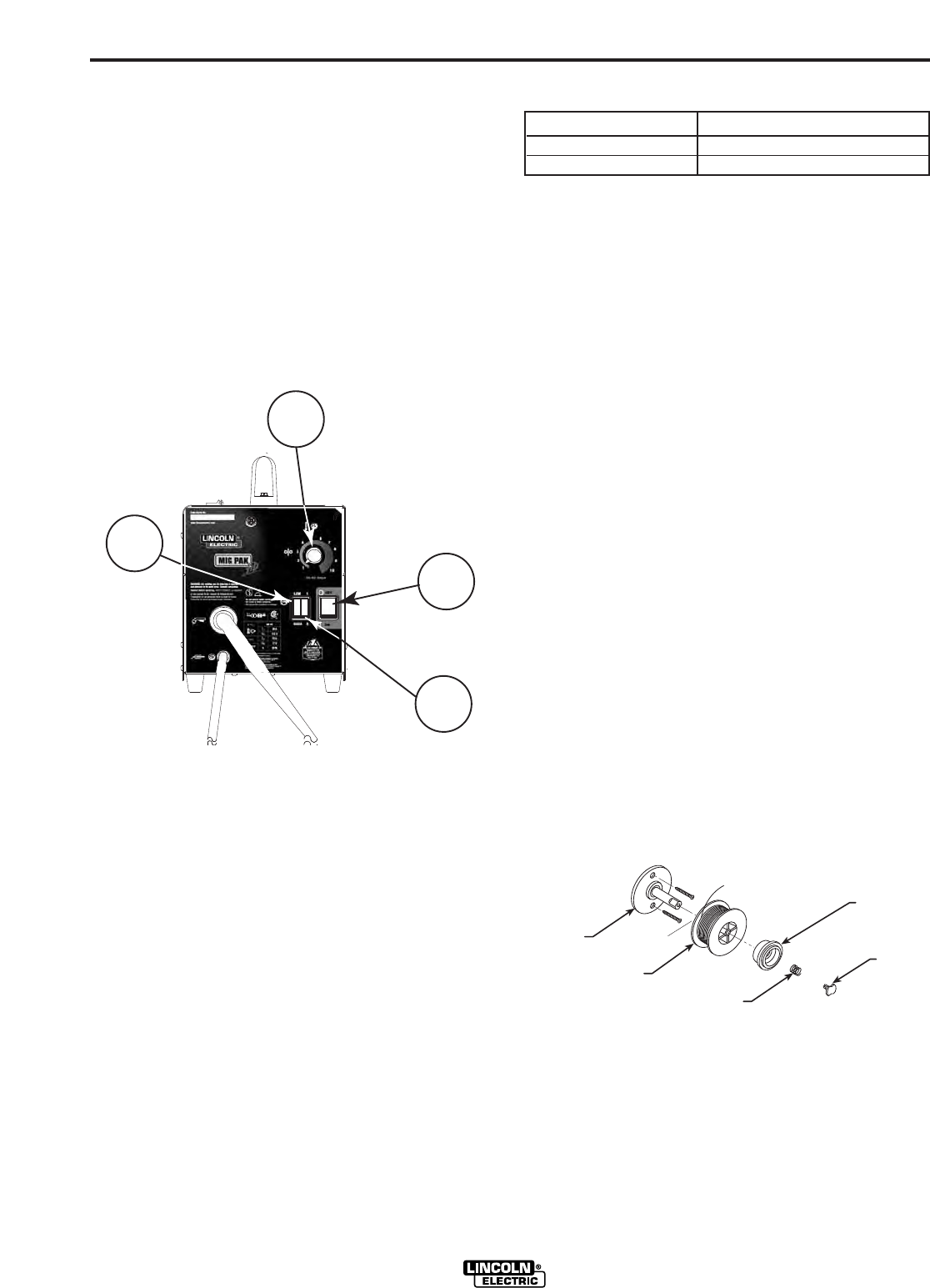

CONTROLS AND SETTINGS

Refer to Figure B.1.

1. Power ON/OFF Switch -When the power is ON

the welding output and wire feeder are ON (“hot”)

when the gun trigger is pressed.

2. Low / High Heat Range Switch. -A rocker switch

control that gives low or high coarse range adjust-

ment of the power source output voltage.

3. 1 – 2 Fine Heat Adjustment Switch. -Allows fine

adjustment of the voltage within the selected Low

or High output range.

4. Wire Speed Control. -Controls the wire feed

speed. Wire speed is not affected when changes

are made in the voltage control.

WELDING OPERATIONS

PROCESS GUIDELINES

MIG WELDING

Table B.1 shows the recommended material/gas

combinations for MIG welding with solid electrodes.

MIG PAK HD

1

4

2

3

FIGURE B.1

SPINDLE

SPRING

SPOOL

LOCK

SPOOL

SPACER

SPOOL

FIGURE B.2