B-20

OPERATION

B-20

POWER FEED™ 25M

GMAW-STT™ WELDING

Surface Tension Transfer, or STT™ welding, is a

break-through process offered exclusively by the

Lincoln Electric Company. STT™ is a low heat, low

spatter process created with Waveform Control

Technology™. STT™ is the process of choice for

open root welding, welding on thin materials or weld-

ing on parts with poor fit-up. Low spatter, even when

using 100% CO

2 shielding gas, results in cost sav-

ings in gas and part clean-up.

Several sets of STT™ weld modes are available.

• Modes 110 and 126 provide individual control of

peak current, background current and tail-out, and

are most often used in robotic applications.

• Modes 123 and 124 include Hot Start and give total

control of the arc.

• Synergic STT™ modes keep the arc characteristics

the same when the wire feed speed is changed.

Note: STT™ is available only with specially equipped

Power Wave power sources, like the Power Wave

455M/STT.

For best results:

• Attach the work sense lead as close as possible to

the welding arc.

• Use only solid steel, stainless steel or silicon

bronze electrodes.

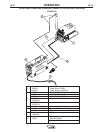

1 K2203-1 Power Wave 455M/STT

K2230-1

POWER FEED™ 10M, Bench Model

K2234-1

POWER FEED™ 10M Dual, Bench Mode

l

2 K2536-1,-2,-3 POWER FEED™ 25M

KP1695-xx, Drive Roll Kit, 2 Roll Feeder

KP1507-xx Drive Roll Kit, 4 Roll Feeder

3 K1543-xx Digital Control Cable

K2683-xx

4

K1796-xx, K2593-xx

Coaxial Weld Power Cable, Lug to Lug

5 K910-xx Ground Clamp

6 K940-xx Sense Lead Kit

7 See Magnum

®

MIG Gun

Literature

Deluxe Regulator for Mixed

8 K586-1 Shielding Gases

Shielding Gas Hose

8

4

3

2

7

1

5

6

FIGURE B.15